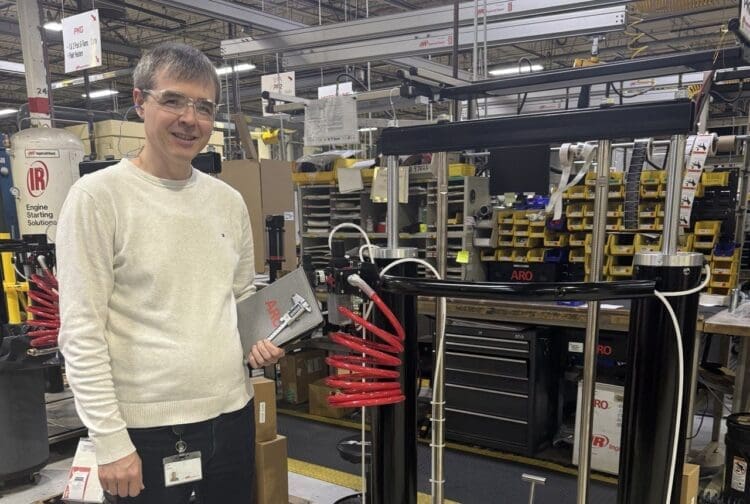

Viktor Sedush, Lifecycle Engineer at Ingersoll Rand, on where real energy savings come from

In 2025, energy efficiency has once again proven to be one of the fastest and cheapest ways to cut emissions and costs. According to the International Energy Agency’s Energy Efficiency 2025 report, global investment in the sector will rise 6 % and approach $800 billion. For industry, this means real savings are no longer achieved simply by buying new “green” equipment, but through a systematic approach to design, manufacturing, and decades-long support.

This is exactly the philosophy behind Viktor Sedush’s work — Lifecycle Engineer for the ARO brand at Ingersoll Rand, an S&P 500 American industrial giant specializing in fluid- and air-handling systems. For over a quarter of a century, he has been responsible for industrial diaphragm pumps that move paints, resins, acids, food ingredients, ceramic slurries, and other difficult media in chemical, food, pharmaceutical, and general manufacturing plants. First in Ukraine, and since 2023 in the United States, His role goes far beyond developing individual components: he leads global cross-functional teams on quality, manufacturability, cost-reduction (VAVE), and innovation (i2v).

The winner of the Cases & Faces International Award and the author of a development that transformed Ukraine’s metal industry, Viktor Sedush, explains how this works in practice: where the biggest energy losses actually occur, and why a single engineer who follows a product from concept to its final day of service can change the economics of entire plants.

Most energy costs appear after the sale

Viktor Sedush immediately debunks a common myth: “The main energy losses occur during the operational phase at the customer’s site. The ratio is usually 20:80 — only one-fifth is spent on production, everything else the customer pays for years.”

Industrial diaphragm pumps have been pumping aggressive or viscous media for decades in places where conventional centrifugal pumps simply cannot cope. And if they are not monitored after sale, within a few years they begin to consume tens of percent more electricity than was stated at the outset. The reasons are simple: internal leaks, seal wear, sub-optimal operating modes, and outdated recommendations.

That is why the concept of “lifecycle engineering” exists — continuous manufacturer support of the product throughout its entire service life, often 20–30 years. The lifecycle engineer receives continuous feedback from factories in the US, Europe, Asia, from service centres, and directly from end users. That feedback becomes concrete improvements: new materials, tighter tolerances, updated operating algorithms.

“A lifecycle engineer is someone who sees the product through the customer’s eyes years after the purchase,” Viktor says. “I constantly receive data from manufacturing, quality, and end users. It lets me eliminate anything that affects energy efficiency and reliability right away.”

From pneumatic to electric drive — removing the biggest source of loss

Just a few years ago,95 % of all diaphragm pumps worldwide still ran on compressed air. Electricity was first turned into pressure at the compressor (30–40 % loss), then the air travelled through pipes (another 10–15 % lost), and only after that was it converted into diaphragm movement. Three unnecessary energy conversions. “The simplest thing we could do was just get rid of the compressed-air stage entirely,” Viktor Sedush recalls.

In 2023–2024, the team he led developed a fully electric diaphragm pump: instead of an air motor, a classic crank-and-rod mechanism driven directly by an electric motor – the same principle that has been reliably working in millions of car engines for more than a hundred years. Viktor himself drew the basic schematic and came up with a new diaphragm clamping system that made the connection absolutely rigid (“like a monolith”) while still allowing the membrane to be changed in minutes with ordinary wrenches. This solution simultaneously reduced unplanned downtime, lowered maintenance labor costs, and improved long-term reliability by eliminating alignment errors and repeat assembly failures common in earlier designs.

“In the end, at the same flow rate, pressure, and pumped media, the pump started using 40 % less electricity than the best pneumatic equivalents,” he says.

At an average power of 3–5 kW, that means hundreds of thousands of kilowatt-hours saved per pump per year — and millions across an entire plant.

Continuous improvement never stops

Launching a new product is only half the journey. Once series production begins, the most voluminous and often the most profitable phase starts. As soon as higher-quality materials, more effective components, or new technologies become available, the team makes changes even to designs that have been on the market for 10–15 years.

For example, in the last two years, ARO pumps have received new polymer coatings, lower-friction bearings, and seals. Every change is rigorously tested for backward compatibility: a customer who bought a pump in 2015 must be able to install the new part without modifying anything. This is genuine long-term support — the kind customers are willing to pay a premium for.

Sometimes the biggest savings require no hardware replacement at all — just the correct model selection and operating regime.

“A higher-capacity pump runs at a lower speed and wears far more slowly. Yes, it costs more upfront, but over its lifetime, the savings on service and spare parts can be several hundred percent of the initial price difference,” Viktor explains.

Real-world example: a customer choosing between an $8,000 pump and an $11,000 equivalent. The $3,000 difference is recouped many times over because the more powerful unit runs at 60 % of maximum instead of 90 %, wear drops 3–4 times, and service intervals extend from 4,000 to 12,000 hours. Over ten years, the savings on maintenance and parts reach $25,000–35,000 — a return of 800–1100 % on the extra investment.

These Total Cost of Ownership calculations are what lifecycle engineers provide to every major customer — and what customers actually pay for, not just the metal.

The non-obvious key to energy efficiency

Back in the early 2000s, Viktor Sedush developed an aeration feeder for metallurgy where powder dosing accuracy of 1–1.5 % saved tens of thousands of dollars a year on reagents and furnace electricity. That development became widely adopted in industrial practice and is considered a meaningful contribution to the modernization of metallurgical processes in Ukraine. In parallel, Viktor authored methodological and technical guidelines used by engineering teams and operators, translating complex process physics into practical, repeatable industrial solutions. His work earned professional recognition, including the Cases & Faces International Award, and led to senior engineering roles involving responsibility for product architecture, cross-functional coordination, and long-term technology strategy across multiple production sites.

“That experience taught me to look for the simplest possible solutions with the fewest moving parts and no pulsations. Pressure spikes always mean extra kilowatts and accelerated wear,” he repeats today.

The same principles formed the foundation of the EVO electric pump and dozens of improvements across the current ARO range.

On the customer’s side, energy efficiency largely depends on the people operating the equipment.

“The main problem with the customer is usually the maintenance staff. That’s why training is our top priority. Our pumps have several operating modes, and choosing the right one lets customers keep energy efficiency at maximum for years,” Viktor emphasises.

The team regularly conducts on-site audits, helps develop standard operating procedures, and keeps documentation up to date. A simple change in start-stop sequence or switching to the recommended speed can deliver additional percentage points of savings — and it works for decades.

When a single engineer oversees a product throughout its entire lifecycle — from the very first idea to its final day in service — energy efficiency stops being a marketing slogan. It becomes a real, measurable value that delivers profit to both manufacturer and customer, year after year, for decades.