You hear about lone worker accidents all the time. “Lone Worker” is not just remote oilfield or pipeline workers in the wilderness. According to Wikipedia, a lone worker can be “an employee who performs an activity that is carried out in  isolation from other workers without close or direct supervision. Such staff may be exposed to risk because there is no one to assist them and so a risk assessment may be required…” That definition covers many activities within the oil industry and others.

isolation from other workers without close or direct supervision. Such staff may be exposed to risk because there is no one to assist them and so a risk assessment may be required…” That definition covers many activities within the oil industry and others.

Up in our neck of the woods in New England, we had a few lone worker incidents that grabbed significant coverage. One involved a worker who was severely injured after falling into a large lathe at a Glastonbury, CT manufacturer DAC Technologies. The 58-year-old man was extricated and airlifted to Hartford Hospital by Life Star helicopter.

Another involved a National Grid worker who fell out of the bucket he was working in and struck wires as he fell approximately 35 feet to the ground.

Given these types of incidents, lone workers are now often supported by cloud-based automated monitoring systems and specialized monitoring call centers – often referred to as an ARC (Alarm Receiving Center) in the UK, or EDC (Emergency Dispatch Center) in the U.S. In fact, Man Down/Lone Worker detection devices have become standard, if not a requirement, for most work sites in the oil and other industries.

Given the gravity of this investment—cost and what is at stake, literally people’s lives – companies need to do their homework when purchasing a man down/lone worker detection device or devices.

Sure, your budget will play a large factor in the system you purchase. Yet to make the best investment for your dollar and provide optimal safety for your workers, you want your man down/lone worker devices to contain the following features:

Man-down (no-motion) detection – If a worker is down and not moving, optimal response time is key. In addition to having this feature, you want a system where you can adjust the alarm time. Many systems will come pre-set to 90 seconds. Different projects and clients can have different safety requirements and you will want a system where you can adjust the no motion setting.

Panic alarm – As the name implies, a worker may not always be able to verbally communicate distress. A device with a panic alarm provides an extra communication tool to alert the command center of a problem.

Live cloud-hosted web software for configuration and emergency response management – With today’s technology, software and firmware updates occur on a regular basis. By having your lone worker/man down system hosted in the cloud, you ensure that updates to the system occur immediately and in real-time.

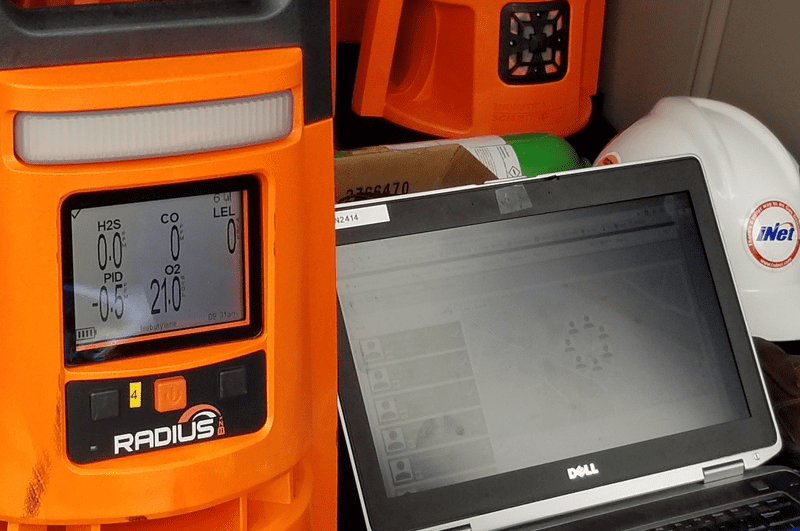

Live gas detection compliance dashboard – This feature eliminates manual data collection, review and reporting. But most importantly it provides a real time view on conditions.

24/7 live monitoring Safety Operations Center – A few providers of lone worker/man down systems will offer 24/7 live monitoring. This is in addition to your own staff keeping a watchful eye and ear on your lone workers. This second set of eyes and ears provides an extra layer of safety.

Push messaging with the live monitoring team – Another imperative for lone workers to be able to communicate by receiving a text for example to “evacuate” or “check-in.”

False detection – This feature enables a lone worker to cancel a pending alert before it is communicated to the command center dashboard. A quick “shake” or resuming movement returns the work-alone device to normal operation.

Automated-prescheduled, wireless firmware updates and device configuration changes – Whether your service is on the cloud or not, you want to ensure your device and firmware are current 100 percent of the time. Automated prescheduled /Pre – Approved updates should be included with any system you purchase.

Customizable system – Most lone worker/man down systems come with pre-set configurations. For many operations, the standard settings will suffice. Yet there are many benefits to purchasing a system that is customizable. For example, should you do government contracts. Many of those might require a system that has shorter no-motion detection (e.g., 60 seconds detection rather than 90 seconds). Think of your lone worker/man down system like an iPhone. You purchase your phone and then in another year a new phone comes out with a few additional features. If you want the additional features, you must buy the new phone. Lone worker/man down devices come in customizable formats so that instead of buying an entirely new system, you can simply add onto your existing one.

Extended warranties – Your typical lone worker/man down devices will come with a two-year warranty. That’s standard. If you have an opportunity to purchase an extended warranty, you should do so. The length of the extended warranties will vary. Our organization offers a five-year warranty. That will typically cover the lifetime of the devices. Extended warranties are an even better idea if the system you purchase is customizable.

Man Down/Lone Worker detection systems vary in price. For a smaller organization requiring five devices, you can expect to spend in the neighborhood starting at $6,000.

You can’t place a value on human life. Unfortunately, price does play a role in the type of system you might purchase. By doing your homework, you can find a system that offers optimal protection for your workers, liability protection, and value for your business.

John V. Carvalho, III is the president of Apollo Safety, Inc. Veteran-owned, Apollo Safety specializes in gas detection products and services for portable and stationary systems.