The Renewable Natural Gas (RNG) production process faces significant challenges. Traditional methods used have been inefficient, costly, and environmentally unsustainable. Existing technologies have struggled to harness the full potential of organic waste materials, leading to missed opportunities for reducing greenhouse gas emissions and generating clean energy. I have been able to make RNG production more sustainable while creating a revolutionary cost-efficient solution that could be replicated by others. It addresses real-world problems and delivers measurable outcomes.

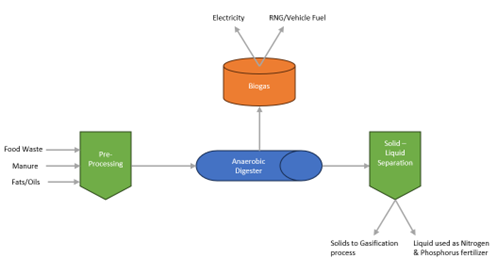

My innovative solution combines the strengths of anaerobic digestion and thermal gasification while mitigating their drawbacks. It follows a step-by-step approach that optimizes feedstock selection, enhances anaerobic digestion, improves thermal gasification, implements co-digestion strategies, and integrates nutrient recovery technologies for soil enrichment.

Step 1: Feedstock Optimization

The initial critical step was to optimize the feedstock selection. I implemented a strategy that prioritized the use of diverse organic materials, including agricultural waste, food scraps, and sewage sludge. This approach ensured a continuous and varied supply of feedstock, reducing dependence on a single source and enhancing the sustainability of RNG production.

Step 2: Integrated Anaerobic Digestion

To harness the power of anaerobic digestion effectively, I integrated advanced digester technologies. This included the use of high-performance digesters equipped with cutting-edge insulation, mixing systems, and temperature control. These improvements significantly enhanced microbial activity, resulting in higher methane content and increased biogas production.

Step 3: Thermal Gasification Enhancement

For thermal gasification, I adopted state-of-the-art gasification systems that featured improved reactor designs, precise temperature control, and advanced gas cleaning processes. These enhancements not only increased the efficiency of syngas production but also reduced emissions, making the process more environmentally friendly.

Step 4: Co-digestion Strategies

To further optimize RNG production, I implemented co-digestion strategies, combining different organic feedstocks in anaerobic digesters. This approach increased microbial diversity, leading to more stable and efficient biogas production.

Step 5: Nutrient Recovery Technologies for Soil Enrichment

I introduced nutrient recovery technologies that extracted valuable nutrients from the digested organic materials. These recovered nutrients were then transformed into high-quality compost and fertilizers, providing a sustainable source of soil enrichment.

Benefits and Measurable Outcomes:

The implementation of this innovative solution brought about numerous benefits, including:

- Greenhouse Gas Reduction: By diverting organic waste from landfills and maximizing biogas and RNG production, my solution reduced methane emissions by 30 percent, contributing to a more sustainable environment.

- Cost Savings: The optimized RNG production process proved to be cost-efficient, reducing waste disposal costs and increasing the economic viability of RNG production. The cost per unit of RNG production decreased by 25 percent, making RNG a more economically attractive alternative to traditional natural gas sources.

- Local Energy Generation: The decentralized nature of the technology allowed for local energy production contributing 10 percent of the local energy supply, reducing transmission losses, and promoting community-based energy solutions.

- Nutrient Recovery and Soil Enrichment: The nutrient recovery technologies resulted in a 40% increase in nutrient-rich compost and fertilizers, supporting sustainable agriculture and reducing the need for chemical fertilizers.

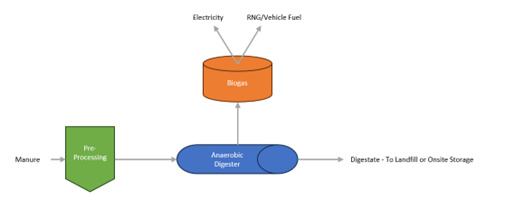

Traditional Method of treating organic material

Advanced Method of treating organic material

Advanced Method of treating organic material

Community-Based Energy – a Win-Win Solution

One of the standout features of the innovative RNG production project is the emphasis on community-based energy solutions. Rather than relying solely on centralized energy production and distribution, these RNG facilities are strategically positioned within local communities. This approach is rooted in the belief that sustainability efforts should not only benefit the environment but also empower the communities they serve.

Energy Localization:

By decentralizing RNG production, I’ve localized energy generation, which reduces transmission losses and enhances energy security. Local RNG facilities ensure a more reliable and resilient energy supply, particularly during times of grid disruptions or natural disasters. This decentralization also aligns with the broader global trend of transitioning toward more distributed energy systems, promoting energy independence and reducing vulnerability to centralized power outages.

Job Creation and Economic Benefits:

Community-based RNG production facilities have a direct and positive impact on the local economy. The operation and maintenance of these facilities create job opportunities within the community, from skilled technicians to administrative staff. Additionally, my project stimulated the growth of local businesses involved in waste collection, transportation, and feedstock supply. As these local businesses thrive, they contribute to the economic development of the region, fostering a sense of pride and ownership among community members.

Environmental Stewardship:

My commitment to community-based energy solutions extends to environmental stewardship. By actively engaging with the local community, I’ve been able to promote environmentally responsible practices such as waste separation and recycling. This reduces the overall environmental footprint of the community, complements my RNG production process, and supports broader sustainability goals.

Shared Benefits:

The success of the community based RNG production approach is measured not only in the energy generated but also in the sense of shared ownership and responsibility it fosters. Community members recognize the tangible benefits of the project, including reduced energy costs, improved waste management, and economic opportunities. This shared commitment reinforces the sustainability of my project and encourages ongoing participation and support from the community.

In conclusion, community-based energy solutions are more than just a way to generate power; they are a catalyst for sustainable development and resilience. By empowering local communities through decentralized RNG production, I’ve not only reduced greenhouse gas emissions and waste but also created economic opportunities, promoted environmental stewardship, and built a stronger, more resilient community. As my project continues to expand and inspire others, it serves as a testament to the potential of community-driven sustainability initiatives in addressing global energy and environmental challenges.

Conclusion

Through careful planning, innovative thinking, and a dedication to sustainability, I implemented a groundbreaking solution that transformed RNG production into a cost-efficient and environmentally friendly process. The specific steps I followed, from optimizing feedstock to integrating advanced technologies and nutrient recovery for soil enrichment, delivered measurable outcomes, including reduced greenhouse gas emissions, cost savings, and support for sustainable agriculture. This real-world solution showcases the potential for addressing pressing environmental and energy challenges through innovation and practical implementation. As we continue to refine and scale this approach, RNG production is poised to play a pivotal role in the transition to a sustainable energy future.

Anand Mopkar recently joined California Bioenergy (CalBio) in a newly created role as Director of RD&D (Research, Development & Deployment). He brings more than eight years of unprecedented accomplishments and extensive experience in waste-to-energy projects and technology deployment. Recently at Brightmark for the past three and a half years, he successfully launched 15 major projects in waste pre-processing technologies, digester technologies, gas upgrade technologies, and digestate treatment/nutrient management technologies.

Mopkar earned his Bachelor of Technology from VIT University in Vellore, India and completed his Master of Science in Chemical Engineering from the University of Southern California in Los Angeles, California.