Oil waste management – more precisely, oil recycling – is a vital component of the energy sector. It ensures the responsible disposal, treatment and reuse of waste generated from oil exploration and production. From fluid logistics and platform cleaning to advanced recycling processes, specialized companies are now at the forefront of creating sustainable systems that align with global environmental goals.

With increasingly stringent environmental regulations and a growing global shift toward cleaner energy, the industry is undergoing a transformation. New technologies, like three-phase separating centrifuge decanters, are emerging that are redefining how we handle waste oil.

Waste Oil: From Environmental Threat to Economic Opportunity

Waste oil is often perceived as a pollutant. In reality, it’s a resource waiting to be tapped. This industrial byproduct once destined for incineration or landfills is now becoming a cornerstone of circular economy strategies. Thanks to advanced recycling methods, up to 70 percent of recyclable waste oil is converted into high-quality base oils, the foundation for premium lubricants.

Beyond lubricants, recovered waste oils are also fueling cement factories and playing a vital role in the steel industry as a substitute for primary fuels, conserving resources and cutting emissions.

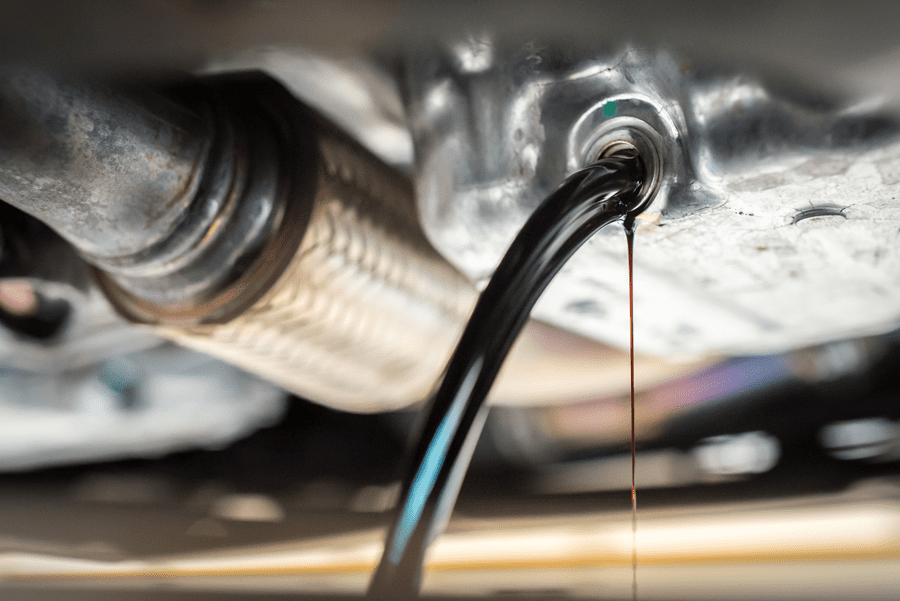

But the stakes are high. A single drop of improperly disposed waste oil can contaminate thousands of liters of water. Efficient collection and treatment systems are critical to prevent environmental degradation while recovering valuable materials.

Regulation and Responsibility: Building the Infrastructure for Change

In the EU – and particularly in Germany – waste oil disposal is tightly regulated under the Circular Economy Act (KrWG) and the Waste Oil Ordinance (AltölV). Retailers are required to accept returned oil, ensuring that what is sold can be responsibly reclaimed. This legal framework helps prevent illegal dumping and encourages safer recycling practices.

A successful waste oil collection network hinges on accessible drop-off points – often at workshops, gas stations and recycling centers – backed by robust logistics that transport waste to treatment plants quickly and efficiently.

Still, challenges remain. Contaminated oils are often too difficult to recycle, and improper disposal remains an issue. Increased enforcement, public education and stronger collaboration between producers, retailers and recyclers are essential to raise collection rates and enhance system accessibility.

Three-Phase Separation: Revolutionizing Oil Recycling

A major breakthrough in waste oil treatment is the three-phase separation system, which dramatically improves both recovery rates and cost efficiency:

- Volume reduction: Sludge is reduced by 80 to 90 percent, lowering disposal and transport costs.

- High-purity oil recovery: Up to 90 percent of usable oil can be reclaimed.

- Water separation: Water, with minimal oil residue, can undergo further treatment with ease.

Example: From 100 tons of waste oil, a three-phase separator can yield:

- 70 tons of clean, recyclable oil

- 20 tons of water with less than 0.2 percent oil content

- Just 10 tons of dry sludge, drastically reducing hazardous waste

Technical Considerations: Explosion-Proof Systems and Operational Safety

The location of recycling machinery determines the level of explosion protection required. Flottweg’s IMO-compliant systems are certified for use in ZONE1 and ZONE2 areas, environments where flammable substances may be present under varying conditions. This ensures safety even under the most demanding industrial scenarios.

Global Waste Oil Market: Growth, Challenges and Innovation

The waste oil market was valued at $74.09 billion USD in 2023, with projections reaching $139.08 billion USD by 2031. Several factors are driving this growth:

- Industrial expansion and rising oil usage

- Stricter environmental standards

- Incentives from oil price volatility

- Advanced recycling technologies

However, hurdles such as contamination, public skepticism and insufficient infrastructure still limit growth. Governments and private players are responding with improved recycling processes, public outreach and international cooperation.

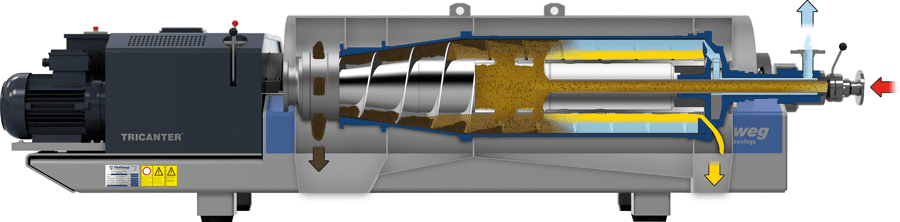

In response to regulatory pressure, more waste oils are now refined instead of burned. Technologies like the Flottweg Tricanter® and Flottweg AC-Separators play a key role here, enabling high-purity separation of solids, oil and water. The Tricanter® is ideal for processing fibrous or heavy solids, while the AC-separator is designed for finer separations when wastewater purity is critical.

If recycling isn’t feasible, waste oil can be burned for energy, but only after it’s cleaned of solids and moisture. These impurities reduce efficiency and increase maintenance issues. Pre-treatment through separation ensures cleaner combustion and better performance.

Technology Spotlight: Inside the Flottweg Tricanter®

The Tricanter® enables simultaneous separation of:

- Solids (heaviest)

- Heavy liquid phase (e.g., water)

- Light liquid phase (e.g., oil)

With features like the adjustable impeller, Flottweg Simp-Drive®, and advanced wear protection, the system adapts in real-time to varying feed compositions, maximizing recovery rates and minimizing downtime. Benefits include:

- Oil purity of up to 99.8 percent

- Solids content reduced to <0.2 percent

- Operational savings via reduced transport and disposal costs

- Long lifespan and low maintenance needs

Real-World Impact

One German company processes over 120,000 tons of liquid waste annually using two Flottweg Tricanters®, operating reliably since 2009 and 2013 without any unscheduled repairs. Located in the heart of Hamburg’s port, this facility recycles oil-bearing waste from ships and industry into:

- Heating oil

- Water clean enough to release into the Elbe River

- Solids safely disposed

This case illustrates how advanced separation technology and responsible infrastructure can turn waste into a resource benefiting both the economy and the environment.

A Smarter Future Starts with Smarter Waste

The story of waste oil is being rewritten. What was once viewed solely as a hazardous byproduct is now recognized as a valuable resource: An opportunity to recover energy, reduce environmental harm, and build a more circular economy.

Thanks to advancements in technology like the Flottweg Tricanter® and stronger regulatory frameworks, oil waste management is becoming more efficient, more profitable, and significantly more sustainable.

But technology alone isn’t enough. A successful transition requires collaboration between governments setting smart policies, companies investing in infrastructure, and consumers participating in responsible disposal. Enhanced collection systems, greater public awareness, and easier access to recycling points will play a critical role in increasing recovery rates and reducing illegal dumping.

The path forward is clear: By turning waste into value, we can protect our environment, conserve resources, and drive innovation in the energy sector. Waste oil is no longer the end of the line; it’s the beginning of a cleaner, more intelligent future.

Headline photo: Waste oil is often perceived as a pollutant. In reality, it’s a resource waiting to be tapped. Photos courtesy of Flottweg.

Stefan Gnose is a Diplom-Ingenieur working as a sales engineer focusing on mining, industrial waste, and mineral oil processing applications. He has a proven track record of providing consultative solutions. Flottweg’s many separation technology solutions achieve tangible success for the customer. With an annual turnover of nearly 300 million euros and an export quota of over 80 percent, Flottweg is one of the world’s leading manufacturers of centrifuges, equipment, and systems. Flottweg knows what is important to operators and works daily with this knowledge to find the optimum solution for its customers. With over 60 years of experience, Flottweg stands for highest product quality: Made in Germany. To learn more, go to Flottweg.