Texas is recognized as a leader in the energy industry with oil and gas production. The Permian Basin in West Texas (if it were a stand-alone country) would rank in the top five global oil and gas producers. Over 50,000 miles of natural gas transmission pipelines, the largest bulk liquid ports in the U.S., an extensive petrochemical network, and of course, a highly trained, specialized workforce of technicians, engineers, scientists and business leaders are just a few of the resources located in Texas that have led to the region’s global leadership in energy.

What many don’t know is that Texas is also the U.S. leader in hydrogen production, transportation and use. About one-third of the nation’s 10 – 12 million metric tons of annual hydrogen production is located in Texas – mostly along the Gulf Coast industrial corridor. This hydrogen is primarily used for refinery operations, ammonia production, and as a chemical feedstock. Over 95 percent of it is generated via a process called steam methane reforming or “SMR” that converts natural gas to hydrogen and carbon dioxide (CO2) with the CO2 being vented to the atmosphere.

Hydrogen’s potential as a clean fuel for a variety of applications beyond its conventional industrial use has long been known. Decades of research and technology development funded by the U.S. Department of Energy (DOE), in partnership with state agencies, industry, non-profits and universities has led to promising low and zero-emissions hydrogen production and end-use technologies that are ready or near ready for commercialization. Power turbines, heavy and light-duty vehicles, steelmaking, and “drop-in fuels,” such as methanol and sustainable aviation fuels (SAF), can all utilize hydrogen – and some already do.

Most of the attention that hydrogen has received recently has focused on “clean hydrogen” or hydrogen with a low “carbon intensity” or CI score. Hydrogen from an SMR typically generates 9 – 12 kilograms (kg) of carbon dioxide (CO2) for each kg of hydrogen produced. While definitions vary, the U.S. DOE has defined “clean hydrogen” as hydrogen with no more than two kg of CO2 per kg of hydrogen produced. To produce clean hydrogen, one must either remove CO2 from the production process and find somewhere to “sequester” that CO2 or utilize a process for hydrogen generation that does not generate CO2. It turns out that Texas is a great place to do both. Discussing CO2 removal and storage is beyond the scope of this article, but there are excellent reports on this topic that can be found at Rice University’s Baker Institute of Public Policy. Among other things, one will find that Texas has literally hundreds of years of CO2 storage reservoir capacity at current rates in the state’s subsurface geology.

It is at this point that one might be asking, “Why are we reading about low-carbon, clean energy when the mantra of the day is, Drill, Baby, Drill?”

To borrow a quote attributed to Mark Twain, “… reports of my death are greatly exaggerated …” In other words, clean hydrogen is still very much alive, and work continues on clean hydrogen projects in Texas and other locations in the U.S. There is a well-established multi-decade trend toward low-emissions fuels that predates the recent focus on climate change, even when the initial cost for those fuels is higher than the fuels they replace. A couple of examples are low-sulfur diesel fuel or using natural gas to replace coal for power production. Both were once thought to be a costly trade-off for incrementally cleaner air.

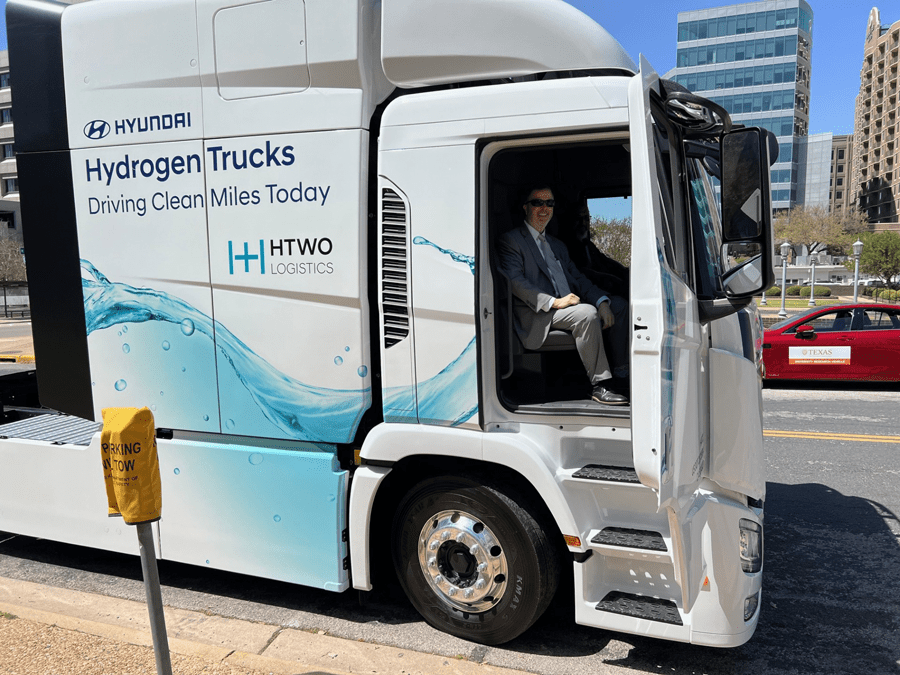

The commercial potential for clean hydrogen can be seen in the development of “mega-plant” projects such as Linde and Woodside’s $2.8 billion plant in Beaumont, Texas, which will utilize clean hydrogen to produce clean ammonia for export. CF Industries’ clean ammonia (also made from clean hydrogen) plant in Ascension Parish, Louisiana, is planned to be operational by 2030. Finally, ExxonMobil continues to move forward with its plan to export clean ammonia (from clean hydrogen) to Asian markets from Baytown, Texas. Other, smaller and/or less developed projects are also moving forward with applications ranging from hydrogen as a heavy-duty truck fuel, to hydrogen for sustainable aviation fuels and “drop-in” fuels such as methanol.

The single most common criticism of hydrogen is its cost. Hydrogen is more costly than many conventional fuels, although not by as much as a few years ago before recent advances in technology. This brings us to another rarely discussed hydrogen application for which cost is perhaps a secondary issue. I am, of course, referring to hydrogen as an energy storage solution.

In Texas, the power grid has a problem. There has been tremendous growth in renewable power generation; i.e., wind and solar. The challenge is that most of the wind and solar power is in the western part of the state, while most of the load demand is in the eastern part of the state. Distance, along with the inherent intermittency of renewable power introduces risks to grid reliability. Adding to the challenges of distance and intermittency, another problem is emerging; electric-grid congestion during periods of high production from wind and solar.

ERCOT, the grid operator in most of Texas, reported in its 2022 “Long Term West Texas Export Study,” (latest edition available) that wind and solar generation capacity in West Texas could be significantly constrained as soon as 2030 when curtailment levels could reach almost 30 percent. Further, the report stated that “technologies beyond typical 345-kV transmission lines would be needed to effectively improve the West Texas export limit.” In other words, we can’t just build our way out of this problem.

The University of Texas’s Center for ElectroMechanics was looking at this problem at the same time, with an eye toward hydrogen as a solution. In a white paper titled, “Renewable Electrolysis in Texas – Pipelines vs Power Lines,” the UT team compared ways to move clean energy from West Texas to industrialized areas along the state’s coast in the most cost-effective – and environmentally benign – manner possible. They focused on a concept called “power-to-gas,” which refers to the production of clean hydrogen from capacity-constrained wind and solar generation as a possible solution for “grid-scale” energy storage. The excess renewable power converts water to hydrogen and oxygen using an electrolyzer. The hydrogen can then be stored or transported via pipeline.

I like to call this process “moving energy across space and time” – space because hydrogen can be transported via pipeline to end use applications far away and time because, once in the pipeline network, it can also be stored to meet hourly or seasonal peaks.

The UT paper concluded that about four gigawatts (GW), or half of the prospective wind and solar-related capacity constraints for West Texas, could be resolved by converting that renewable energy to hydrogen and transporting it to the Houston area (one of the world’s largest hydrogen production/consumption hubs) via a large hydrogen pipeline. That represents almost 25 percent of the Houston area’s use of natural gas-sourced hydrogen via SMRs. The alternative for moving that same electric energy to Houston would be the construction of five 345-kV electric transmission lines. Let’s repeat that: One pipeline or five electric transmission lines to move an equivalent amount of energy!

The breadth of potential end-uses for clean hydrogen is illustrated by the Texas Hydrogen Alliance (THA), the central advocacy group for hydrogen in Texas. THA members include global energy companies, automakers, engine manufacturers, chemical exporters, ports, universities and convenience store operators, just to name a few. Each of these organizations shares a common belief that hydrogen has strong commercial potential and can provide economic, health and societal benefits to consumers for the growing list of hydrogen end-use applications.

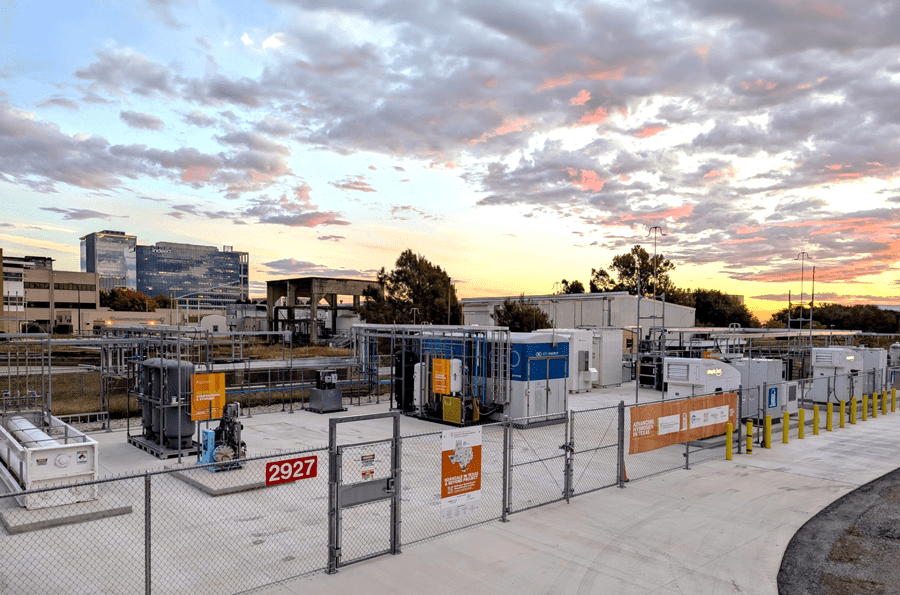

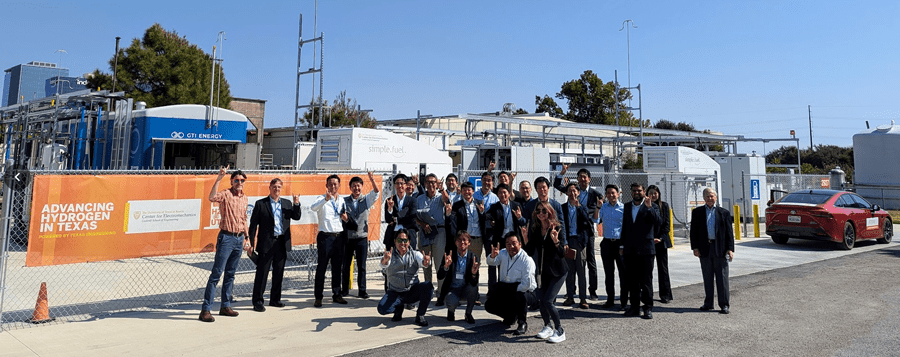

Headline photo: GTI Energy and the University of Texas manage a DOE-funded “protohub” facility in Austin, Texas, which is a testing and training ground for hydrogen operations, supported by 14 industrial partners with hydrogen operations in the region. Photos courtesy of Michael C. Lewis.

Brian Weeks is the Senior Director, R&D Business Development for GTI Energy. GTI is an independent, not-for-profit research and development institute that has been bringing innovative technology to the energy industry for 80 years.

In his current position, Weeks leads the creation of large-scale technology demonstration and validation programs for public-private partnerships, primarily with the U.S. DOE and GTI Energy’s many industry clients. These programs address advanced fuel and delivery infrastructure systems for hydrogen, natural gas and renewables. A recent key role was his leadership in organizing the Gulf Coast clean regional hydrogen hub (HyVelocity) where he continues to lead stakeholder outreach initiatives.

Weeks also serves on the board of the Clean Hydrogen Future Coalition and as an advisor to the Texas Hydrogen Alliance. He was also appointed to the Texas Railroad Commission’s Hydrogen Advisory Council. He is a sought-after advisor on technical, market and regulatory issues surrounding the introduction of emerging energy technologies, especially those involving hydrogen, in which he has over 25 years of experience.

Weeks is a graduate of Vanderbilt University where he received his undergraduate engineering degree. He also has an MBA and is a licensed Professional Engineer in the State of Texas.