Predictive maintenance (PdM) is indisputably the future for the oil and gas industry, which relies on reliably functioning physical assets for the production that drives revenue and growth.

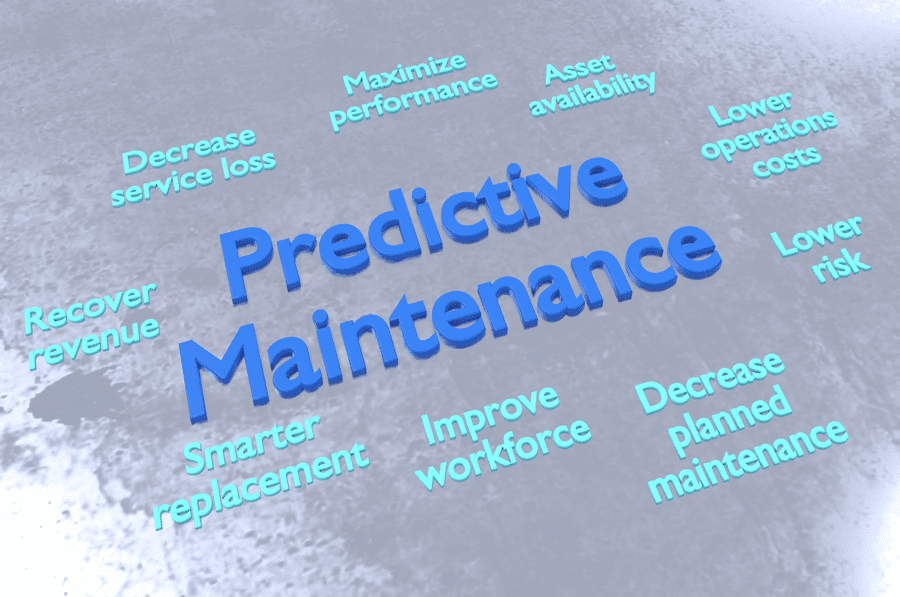

The benefits of a predictive maintenance approach are clear. As sensors and machine learning work together to pinpoint issues in advance, operators can better plan maintenance schedules, circumvent issues, and significantly reduce both unexpected non-productive time (NPT) as well as secondary damage caused by faulty equipment. Simultaneously, as assets spend less time in the shop, they are available to service more jobs with the same amount of equipment. There’s a human impact upside, too; reducing environmental, health and safety (EHS) risks helps workers stay safe and productive on the job.

Crucially, the advantages of a PdM approach add up to major savings: The annual estimated cost of unplanned downtime is $50B. In fact, oil field services company Schlumberger saved $8M in under a year of implementing a predictive analytics program that forecasts equipment issues for fracturing pumps, and acknowledged a similar program would generate savings in excess of $30M in three years.

But while PdM is by far superior to condition-based maintenance and more reactive alternatives, a pure machine learning approach has some limits, which is why adding physics-based modeling can be a gamechanger, improving cost savings, efficiency and effectiveness.

Access to Data is Often a Question Mark

In the oil and gas industry, adoption hasn’t been widespread; less than 25 percent of oil and gas operators are using predictive maintenance strategies. The lack of adoption isn’t altogether surprising. Accurate prognostics rely on very specific data: previous examples of faults and run-to-failure. But if companies don’t have a rich historical trove of this data at their fingertips, it’s time consuming and expensive to invest in the infrastructure required to collect it. Additionally, the lead time these solutions provide is often a few weeks, which is not always enough time for operators to act on data-backed predictions in a meaningful way.

Consistency is Key

The requirement to have data at your fingertips is not the only obstacle to a pure machine learning solution. There’s also the question of asset instrumentation. Are sensors on all relevant pieces of equipment? Are the same sensors on the same assets across all your sites so you can have an apples-to-apples comparison? Are data recorded consistently? Is it always in the same format? Do you have the same number of sensors at each site? Are all sensors labeled correctly?

The classic computer science adage – “garbage in, garbage out” – has endured these many years for a reason. If you have imperfect, inconsistent data, you will not get the accurate, data-backed insights that will allow you to predict and plan with confidence.

Predictive Maintenance is Still the Best Option

No matter what, PdM is the best alternative available, especially when compared to its predecessor, condition-based maintenance (CBM), which does not provide sufficient notice to plan shutdowns, replace parts and mitigate cost. A recent study underscored CBM’s lingering popularity: 41 percent of plant managers are still turning to this reactive maintenance approach despite its severe limitations.

It’s a missed opportunity to build a more proactive, predictable and sustainable maintenance system when – thanks to algorithmic and hardware advancements – these benefits are more within reach than ever before. Sensor technology has only gotten more sensitive, varied and inexpensive. Meanwhile, machine learning and artificial intelligence continue to mature, better able to identify patterns and make informed recommendations that plant owners, operators and managers can be confident in. Collectively, this evolution in innovation is the reason predictive maintenance will be the standard for most asset-heavy industries in the very near future. That said, its advantages can be realized even sooner with physics-based modeling.

Physics-Based Modeling Advances Predictive Maintenance

In the typical PdM solution, it’s not uncommon for data scientists to work closely with a plant’s operations team for a year-plus to generate the solid pipeline of data necessary to train machine learning models well enough to make accurate predictions.

But what if you don’t have a year to wait?

A blended approach of physics models with data science makes it possible to move much faster (think months, not years). Like data-driven predictive maintenance, this starts with evaluating current data, understanding how the collection process works, identifying the most problematic equipment types, and prioritizing the highest ROI fixes. Physics-based modeling makes intelligent use of understanding how different equipment types function. Through physics-based simulation, we can better predict when and how this equipment will fail with a higher degree of certainty, improving a plant’s ability to plan and prevent these issues.

For example, using a physics-based model tuned to a reciprocating process compressor, we were able to detect valve leakage simulated in hardware with over 99 percent accuracy. Moreover, a physics-based algorithm can also distinguish between valve location (i.e., suction or discharge) without any pre-training. Since the physics-based algorithms are more sensitive to leakage severity, fault detection often occurs weeks in advance of purely data-driven approaches.

Pre-training for the Win

There’s another reason physics-based modeling is such a powerful approach to predictive maintenance: You don’t start from square one every time. No matter if you specialize in upstream, midstream or downstream operations, you can reap the benefits of physics-based models that have been developed for different equipment types and the unique signals that indicate incipient faults or failure. As these models are effectively “pre-trained,” it can take as little as a month of ingesting new data to calibrate a model to a specific geometry and operational pace and start seeing actionable insights.

Looking Ahead

Oil and gas companies are facing market volatility, a sluggish supply chain, and high CapEx and operations and maintenance expenditures. Additionally, the hefty cost of NPT matters greatly, an assertion underscored by industry research from Kimberlite, which found that a one percent downtime rate (just under four days) adds up to $5M+ annually.

In short, there is no reason to delay – and every reason to move quickly – to explore implementing a predictive maintenance approach augmented by physics-based modeling.

Neil Eklund is one of the most innovative, forward-thinking researchers in the field of Prognostics and Health Management (PHM). With 20 years of deep technical experience in machine learning, data science and industrial analytics, Dr. Eklund serves as principal data scientist at Novity, the industrial predictive maintenance venture recently launched by Xerox PARC. Before joining Novity, Dr. Eklund served as the chief data scientist and scientific advisor at Schlumberger, where his work led to the creation of a new PHM-focused business segment, Technology Lifecycle Management. Prior to that, he spent 14 years in the machine learning laboratory at GE Global Research where he was responsible for bringing advanced analytics as a shared service to GE businesses for better and faster utilization of the company’s industrial data assets. Dr. Eklund holds a PhD in Machine Learning and he is also a PHM Society Fellow.