When it comes to skilled occupations, classroom learning can only take you so far. As with many industrial and factory-based jobs, experience and knowledge are built up over time for workers in the oil industry. While new workers can certainly enter the field with a basic understanding of what the job actually entails, it takes years of hands-on experience before they’re fully skilled and confident in their abilities.

Novice oil workers often turn to the old-timers as they learn the tricks of the trade. Yet veteran oil workers are retiring in droves, tasked with passing the torch to the next generation of industry leaders and workers. How can those industry veterans help prepare the next generation of oil workers, amidst technological advancements and political turmoil?

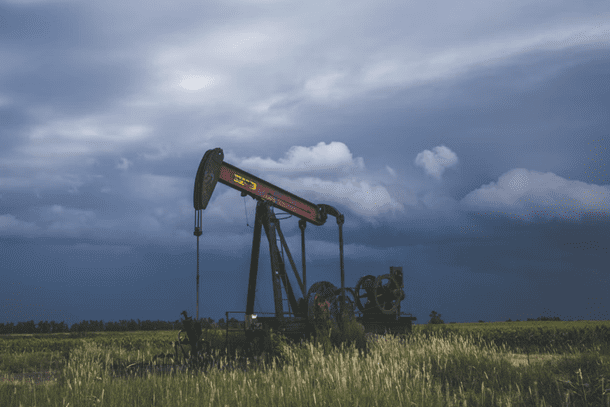

To move in the right direction, oil industry leaders must take measures to address the skill gap while ensuring proper training of workers and improving safety measures. From petroleum engineers to oil roustabouts, the success of oil hinges on the workers who handle the everyday processes that keep the world running. It’s time to prepare the next generation of oil workers for success — here’s what you need to know.

Passing the Torch: Changing Generational Perceptions

Recruiting oil workers is a time-sensitive issue, as veterans are retiring in droves. In addition, many of the workers that were laid off due to the COVID-19 economic downturn never returned. The general public’s trust in oil and gas has also waned in recent years, primarily due to the purported environmental impact of oil extraction. Young people are of particular note in this regard: In a recent poll, 75 percent of adults under the age of 30 said they favor alternative energy over fossil fuels, based on environmental factors alone. This example represents one of the biggest generational issues facing the oil industry.

As employment cyclicity in oil and gas continues to rise, recruiting skilled workers should be a top priority for industry leaders. Not only does the industry need to attract workers; however, it must also retain employees of every job description in the long run. To achieve that goal, companies must keep workers happy and safe, which can be a challenge when it comes to the oil industry.

It should come as little surprise that oil extraction is one of the most dangerous occupations in the world. While oil fields, rigs, and other job sites are held to strict safety standards, mistakes unfortunately occur, and accidents can happen to even the most skilled worker. Common safety hazards in the oil and gas industry include the risk of fires and explosions, mechanical malfunctions, and work in confined spaces, to name a few.

The good news for aspiring oil workers is that the industry has come a long way in terms of safety measures. Today, industry leaders utilize a variety of tactics in the name of employee safety and efficiency, such as signage and training programs. Posting easy-to-read signs with clear images is an easy, cost-effective way for employers to spread the word about safety hazards and ways to prevent them.

Addressing Skill Gaps in the Oil Industry

Although the image of roughnecks is what typically springs to mind upon mention of an “oil worker,” the reality is much different. The good news for young people who may be reluctant to perform manual labor is that there are various types of jobs within the oil and gas extraction subsector. Industry career options span from oil field roundabouts to geoscientists, pump system operators, and beyond.

Likewise, worker salaries can also vary considerably. For example, the number of petroleum engineers employed in the oil and gas industry in 2021 exceeded that of roundabouts, reports the U.S. Bureau of Labor Statistics. Petroleum engineers are among the industry’s highest-paid, bringing in a median annual salary of more than $141,000. By comparison, oil and gas roustabouts can expect to earn $46,990 annually.

In order to work as a petroleum engineer or similar professional, an advanced degree is often required. The same doesn’t apply to roughnecks and roustabouts, however. Working in a manual labor position requires a broad skill set, much of which can only be cultivated in the field. In an effort to address workforce skills gaps left behind by retiring veterans, hands-on learning can help new workers get up to speed quickly. Site managers and those tasked with training new recruits should also encourage open dialogue and questions from their workers.

Keeping Future Oil Workers Safe and Happy

Extracting oil is a demanding line of work that comes with its fair share of hazards. The next generation of oil workers must recognize those potential dangers, and learn how to do their job efficiently and accurately, despite any challenges that exist. Veteran workers can help keep the industry alive by sharing their knowledge with those young workers before that valuable data is lost to history.