When you picture an American jet fighter on a critical mission or the latest electric vehicle (EV) rolling off a factory line, you may not realize that several of the key materials that drive these technologies, including tungsten, come from halfway across the world. Although tungsten is a critical mineral prized for its unmatched density, high melting point, and hardness, the U.S. has gone more than 10 years without producing a single ounce domestically, relying instead on foreign suppliers to fuel innovation. This gap leaves everything from national defense to high-tech manufacturing vulnerable to disruptions in the supply chain at any time and underscores the urgent need to secure a reliable supply at home. To further understand the stakes and why the current U.S. supply gap is so concerning, let’s examine how tungsten is produced and who controls it worldwide.

Current State of Tungsten Supply

Today, the global tungsten market is overwhelmingly dominated by China, which produces roughly 80 to 90 percent of the world’s supply. Other countries contribute only small fractions, leaving the U.S. highly dependent on foreign sources for this critical mineral. Historically, the U.S. once had a modest tungsten industry, peaking during the mid-20th century when domestic mines supplied defense and industrial needs. Over time, however, production declined due to competition from cheaper imports, high extraction costs, and dwindling reserves, eventually reaching zero over a decade ago. This absence of domestic supply has left the U.S. vulnerable to shifts in global markets, trade disputes, and geopolitical tensions. In other words, relying almost entirely on foreign producers, particularly one nation with outsized control, significantly decreases our ability to respond quickly and independently in moments of crisis.

National Security Implications

Therefore, restoring a domestic supply of tungsten is about more than just mining a mineral; it’s a matter of national security, industrial resilience, and economic strength. The U.S. reliance on foreign tungsten leaves defense programs, from aircraft to armor-piercing munitions and advanced weapon systems, vulnerable to export restrictions, tariffs, and geopolitical tensions. A secure domestic supply would ensure uninterrupted access for critical defense applications, reducing vulnerabilities in military supply chains, and safeguarding the operational readiness of U.S. forces.

At the same time, tungsten powers high-tech industries such as semiconductors, electronics, and EVs, making reliable access essential for innovation and growth. It also plays a key role in emerging technologies, including fusion energy research, which could shape the future of sustainable power. Bringing tungsten production home would provide a stable foundation for defense, empower industries to develop new technologies without supply-chain uncertainty, create high-skilled jobs, and strengthen regional economies. In short, restoring domestic tungsten supply would transform a vulnerability into a competitive advantage for both national security and technological leadership, making it something the country can no longer afford to ignore.

The Reality of Restoring Domestic Tungsten Supply

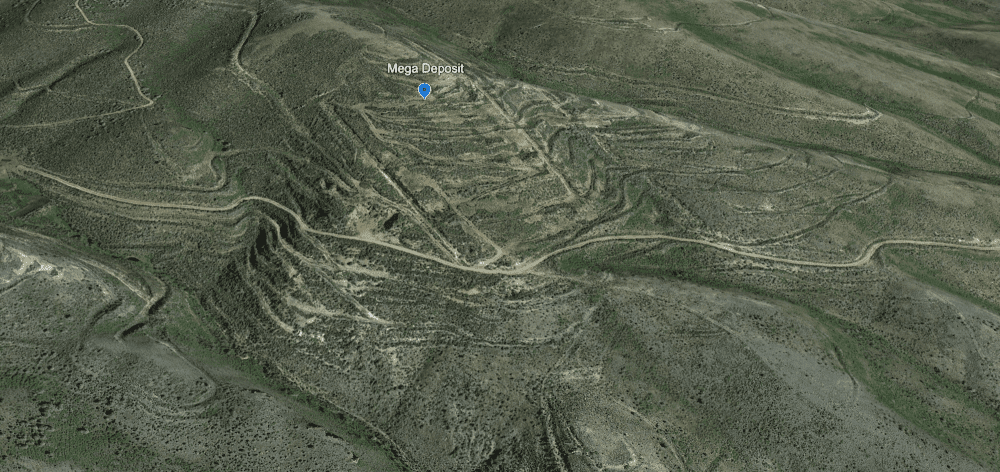

Restoring domestic tungsten supply will require a coordinated effort across government, industry, and research institutions. Identifying and developing untapped domestic deposits is the first step, followed by investing in modern mining and processing facilities capable of producing high-purity tungsten for both defense and industrial applications. Industries from aerospace and defense to electronics, semiconductors, and EVs all depend on tungsten, and even short-term shortages could stall innovation, delay production timelines, and drive up costs across these critical sectors, underscoring the urgency of building a stable domestic supply.

Public-private partnerships and targeted incentives could encourage companies to take on the upfront costs of extraction and refinement, while research into more efficient and environmentally responsible methods could make domestic production economically sustainable in the long term. Strategic stockpiling and supply chain planning would further ensure that critical industries and military programs maintain uninterrupted access, even during global disruptions. Together, these measures could establish a resilient supply chain that strengthens both economic growth and technological competitiveness.

The Necessity of a Stable Domestic Supply

As we see it, restoring domestic tungsten supply is no longer optional. Securing reliable access would strengthen national defense, reduce reliance on foreign sources, and empower industries from aerospace to electronics, semiconductors, and EVs to innovate without the constant risk of supply disruptions. A stable domestic supply would create high-tech jobs, bolster regional economies, and provide the U.S. with a strategic advantage in both security and technology. It would also mitigate risks associated with overreliance on foreign suppliers, particularly China, ensuring that critical materials remain accessible even amid global uncertainties. Although the challenges are real, the opportunity is clear: By investing in domestic tungsten production, the U.S. can transform a long-standing vulnerability into a foundation for resilience, innovation, and global leadership.

Photos courtesy of Patriot Critical Minerals Corp.

Brodie Sutherland is the CEO of Patriot Critical Minerals Corp. A dynamic CEO and professional geologist with over a decade of experience leading mineral exploration across 20-plus countries, Sutherland excels in geological mapping, sampling, and drilling to unlock critical mineral resources. For more information, visit Patriot Critical Minerals Corp.