Environments in oil and gas wells are harsh, complex and abrasive, wreaking havoc on drilling systems and equipment, which are especially difficult to replace or repair when in boreholes miles underground. For manufacturers in this space, industrial 3D printing, known as additive manufacturing (AM), has been a game-changer.

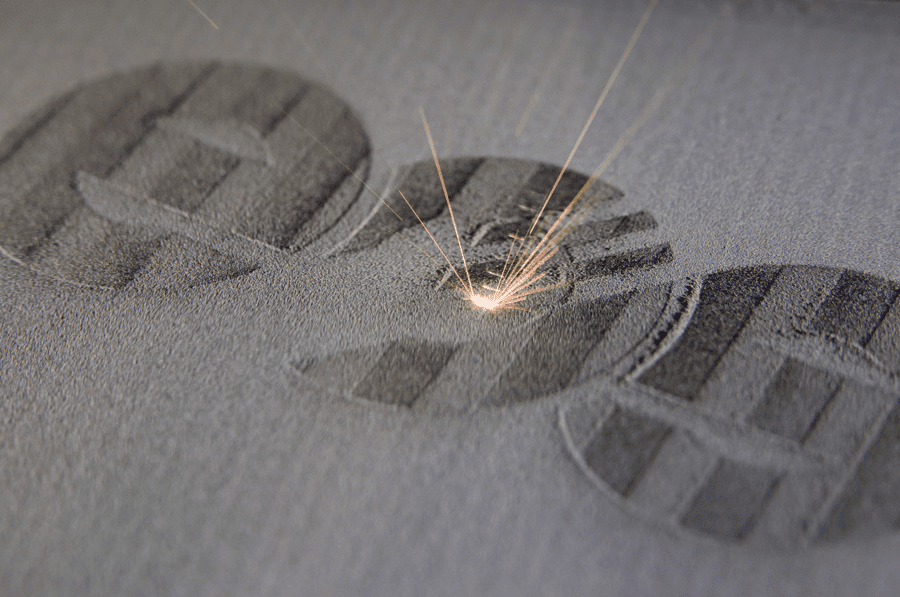

AM technologies showed early success in the oil and gas industry by producing plastic components, but they lacked durability for all drilling applications. Today, with AM’s advancements, specifically printing durable metals like (stainless) steels, nickel alloys and copper alloys, enables companies to design products meant for extremely challenging drilling tactics and complex geometries.

And the industry is taking notice. Major industry players, like BP, Shell and Total have begun establishing Joint Innovation Projects (JIPs) to develop guidelines and economic models for using AM in the oil and gas industry. In fact, it’s estimated that within the next five years, 3D printing in the oil and gas market will be worth $32 billion. By 2030, it’s expected to be worth over $60 billion.

Benefits of Industrial 3D Printing

It’s no surprise the AM market is anticipated to boom within a decade; it just makes business sense. For manufacturers supplying and servicing the oil and gas industry, AM helps validate designs faster and reduces time to production. AM produced applications are often more durable compared to their traditionally produced counterparts, allowing for complicated features like a variety of lattice structures and thin but durable webbing or complex channels which can increase the performance of applications such as drills, injection nozzles for gas turbines and even turbine blades. In fact, according to Siemens, “If you can 3D print a turbine blade, you can print pretty much everything.”

Reduced costs and time to market aren’t just appealing to manufacturers. Customers also benefit from increased drill accuracy, reduced drilling times, and fewer maintenance disruptions through smart and hybrid AM repair models.

If we look at the supply chain aspect of AM, distributed manufacturing concepts with digital inventory also create tremendous benefits for CAPEX heavy industries such as oil and gas. Simply put: 3D printing on-demand. Because there is a lot of maintenance in the field, organizations only have two choices – on-site warehousing, which leads to large amounts of working capital, or fast supply, which creates high transport costs, especially in far-flung locations, like North Dakota or on a rig.

Common Challenges

Though the benefits are clear, as AM continues to grow in the industry, many businesses aren’t making it beyond pilot mode. Although every organization has a unique implementation journey, when we look at companies who have struggled with AM, there are many similarities. Namely, bringing on AM is a change strategy, just like when you implement any other novel technology. And, like with any digital transformation, it involves rethinking your design processes, your manufacturing philosophy, and your value and supply chains – a process that’s easier said than done.

Let’s back up for a second and revisit this idea of optimizing value chains through AM.

The “manufacturing” part of “additive manufacturing” refers to the full end-to-end manufacturing process journey, involving a large number of people, processes, and decisions. This is known as the value chain – the entire universe of people, processes, and organizational infrastructure that goes into the process of creating and delivering goods, starting within research and development (R&D) through production all the way through to marketing and aftersales.

The AM process is similar to traditional manufacturing, which has a complex value chain in itself:

- The efforts begin well before and extend well beyond production.

- You need experts within your organization to identify where and when AM makes sense.

- You need technical specialists to define product specifications.

- You need designers and engineers to ensure that your products meet those specifications.

- You need experts to explore and validate the materials that can be used.

- And of course, you need to define and refine the manufacturing processes to make it happen.

So, imagine what it takes to transform, improve and optimize every link in that chain. That’s what’s involved in successful AM implementation.

Steps to Ensure Your Company is AM Ready

Overcoming challenges, putting them into perspective, and seeing them as “growing pains” are all part of ensuring your organization is in the right place to succeed. There are a few critical components to keep in mind in this vein as you begin your AM journey.

1. Start with the end in mind

Here’s the good news: The first and most crucial step in any AM journey doesn’t involve costly investments in technology at all. It involves looking inward at your organization and defining your challenge and desired end goals. Part of this includes identifying where you’ll need new knowledge and expertise.

No one knows what form 3D printing will take in the beginning. That’s the point of starting with your long-term strategy and determining the smaller, more incremental objectives that will help get you there.

2. Rethink how you think of innovation

By beginning the process now, you’re putting the organization in a better place to explore AM at scale. While your first steps may be modest, they’ll work toward more significant 3D printing strategies. AM is an agile technology. It’s not just a small project that starts with one person or application and scales up. It’s built to move quickly and scale rapidly throughout your organization. With industrial 3D printing, you can build parts overnight and take them through multiple iterations. This process works best if your company is set up to be an agile organization.

Currently, many companies still innovate in waterfall structures. There’s a very linear approach with waterfall methodologies that follows a define, design, develop, test and implementation process. On the other hand, agile models develop in circular spurts and close to the customer in quick iterations. Coupled with 3D printing, agile is the only way you can increase knowledge throughout your value chain and make sure the journey is clear to all related functions.

3. A single “AM team” isn’t the best approach

As you can see, industrial 3D printing is an entirely different way of thinking. This means creating agile teams that aren’t bound by traditional methods and setting up your organization so you’re optimizing that approach. Ideally, you’ll need people from all parts of your business with in-depth knowledge of 3D printing who can also work together fluidly. Something that works well in this regard is the “Team of Teams” approach.

Popular in the software development space, “Team of Teams” means people can still operate in their current hierarchical structure. At the same time, they can also form teams cross-functionally by not taking any existing hierarchy or function into account. In this approach, it’s not unusual for a member of the executive team to be on another team in a non-leadership role. Instead, they might be led by a lower-level leader (making executive buy-in and support that much more important).

Agile team setups create an open work environment. They provide opportunities to pull people in as needed to make sure you have all of the necessary expertise on a particular project.

4. Your AM journey will be like no other

Remember, industrial 3D printing isn’t as easy as turning on a printer. It requires extensive prep work and buy-in from all levels of your organization. And even if your competitors are already using 3D printing for similar applications, how you use AM can (and should) be sculpted to your specific needs.

There will be failures and challenges. But if you let your in-house knowledge and business objectives define how you deploy additive manufacturing throughout your organization, then you’re ready and primed for success.

Headline photo courtesy of EOS

Fabian Alefeld is the North American manager for EOS’s Additive Minds consulting practice, which works

with organizations across a variety of industries to maximize their efforts at every stage of the AM journey from start to part. For more information, visit www.eos.info. In May 2020, AMCM, an EOS Group company, announced its AMCM M 4k-1 (single laser) and AMCM M 4k-4 (four laser) industrial DMLS metal 3D printing platforms, which offer high-performance, customizable platforms ideal for oil and gas applications.