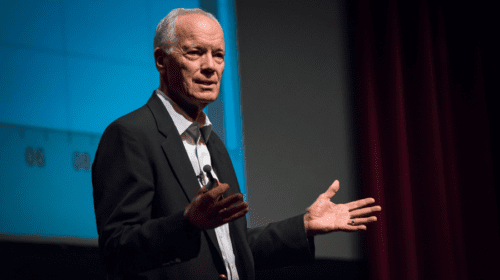

The founder and CEO of BMA Biotech, Mark Bullock is no stranger to the oil and gas industry. Both Bullock’s step-father and father-in-law have both worked in the industry for over 40-years. So, it is little wonder how a small-town boy from the United Kingdom is now living in Sugar Land, Texas and providing highly effective products and sustainable services to the O&G industry.

“BMA Biotech is a family owned company, with long and established ties in the oil and gas industry,” Bullock said.

To aid Bullock in the development of his first range of oilfield chemicals, he built up a team of scientists and petroleum engineers who all had considerable experience within the industry. This would ensure that not only were BMA Biotech’s oilfield chemicals highly-effective in their application, but also, it would make sure that the products were sustainable and reduced risks to health, safety, and the environment while being 100 percent biodegradable within 75-days.

Bullock said within a few short weeks of the release of their newly developed oilfield chemicals in early 2017, their professional network and new clients within the industry begun to voice concerns regarding a number of oil spill cleanup products used in the industry, which was akin to snake oil.

“Our clients continually chose BMA Biotech to undertake field assessments and the implementation and execution of treatment plans, as all of our field personnel have extensive site evaluation and both soil and water remediation treatment experience, in the continental United States, United Kingdom, Europe, and certain regions in the Mid-East,” Bullock said. “I know it is different in every state and country, but in Texas it is called the Responsible Party. Basically the company that causes the spill, for lack of better words, is the one legally on the hook for the clean-up.”

Bullock listed off a few PT Barnum-esque claims he was aware of, which ranged from turning crude oil into non-harmful sand to other spurious claims which were scientifically impossible.

“Look at what they are telling you about their products and actually just Google it,” Bullock said. “You’ll find more than enough academic research out there to prove or disprove their theory.”

To ensure that BMA Biotech was able to develop a more effective range of spill remediation products, they added new members to their research and development team which had over 40-years of experience in oilfield remediation sector.

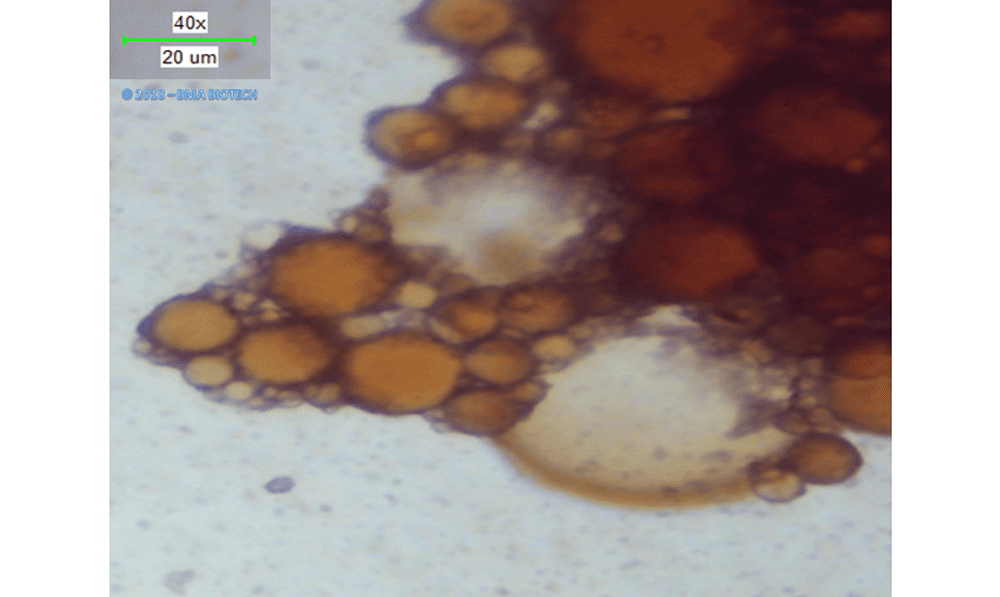

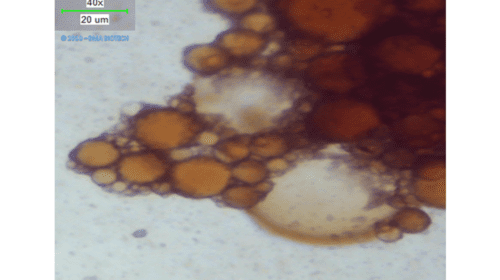

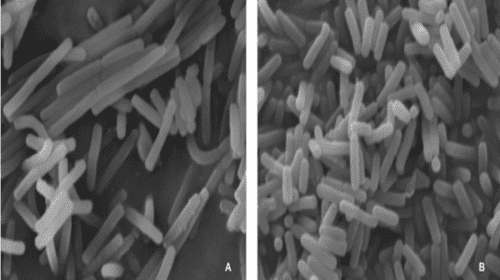

By early 2018, BMA Biotech had released their first ex-situ soil wash chemical and in-situ/ex-situ microbial based spill remediation products. Bullock said, their bioremediation product differs from conventional products as they don’t use bulking agents – such a vitamins and their bioremediation product contains a wider spectrum of microorganisms than any other microbial based remediation product.

“We developed a microbial remediation product and we proved our formulation by adding more microorganisms than any other product on the planet,” Bullock said. “Which is far more sustainable and effective.”

He then went on to say how their ex-situ chemical treatment differs is that it can be separated from oil/petrochemicals and then re-used. In addition, the oil/petrochemicals can be recovered and sold as a commercial commodity.

“We pride ourselves on setting the standards, for others to follow. We only resort to ‘dig and haul’ as a very last resort, or if state agencies prefer this method of oilfield contamination cleanup. We stand behind all of our remediation products, and only deploy the most effective types of treatment methods. We do not mis-sell our products, nor do we make false or inflammatory claims about our services and capabilities of our products,” Bullock said.

Initially, it seemed that the PT Barnum-esque companies were being countered by BMA Biotech’s new remediation products, to some degree. But Bullock knew he had to step up to the next level when a company basically told him to assist them in a clean up mess from one of the snake oil companies operating in the oilfield.

“We have over 40-years of hands-on experience in providing Phase I and Phase II environmental site assessments and delivering effective soil and water remediation programs to a diverse range of oil and gas companies around the world,” Bullock said. “We believe our oilfield environmental services are world-class and provide a true ‘cradle to grave’ approach to the cleanup and successful remediation of oilfield contamination.”

Jason Spiess is a multimedia journalist, entrepreneur and content consultant. Spiess has over 25 years of media experience in broadcasting, journalism, reporting and principal ownership in media companies. (Over 30 years experience if you count his adolescent years as a newspaper delivery boy learning the importance and logistics of daily distribution and monthly door-to-door bill collecting.) Spiess has worked in the areas of oil and gas, UAS and precision agriculture, health care, cannabis, agriculture, real estate, government affairs and economic development. Spiess is the host of two radio programs, Building the Bakken and Coffee & Capitalism, and three specialty programs, MonDak OilField Review, Corporate Ink and UnStuck, that carry a radio network that spans five states and two countries. Spiess is a North Dakota native and graduated from North Dakota State University.