Multi-element, automatic self-cleaning strainers optimize upstream and downstream production, while minimizing maintenance and downtime

For the oil and gas industry, coarse filtration of various fluids is critical to ensure reliable production, extend the life of a wide variety of upstream and downstream equipment, and increase the intervals between backwashing or necessary maintenance.

Upstream, production wells often use coarse filtration (from 30-100 microns) to remove sand, solids, or debris during secondary phase waterflooding, where clean filtered water is introduced into a rock layer through injection wells to push residual oil to operating wells.

Deep water rigs may prefilter seawater to remove solids before further filtration for uses ranging from enhanced oil recovery, to heat exchangers, to producing potable water.

Upstream, when oil is produced, liquid separation is used to separate produced water from the oil. Coarse filtration may be needed during the produced water treatment.

In downstream applications coarse filtration may be 125-3200 microns. Refineries often prefilter raw water from lakes, rivers, and aquifers to remove organic, aquatic, and other solids, which allows fresh water to be used as process and cooling water. In cooling towers, filtration can improve cooling efficiency while reducing fouling and plugging. In process equipment, the removal of suspended scale and debris from heat exchangers and cooling systems can prevent the clogging of equipment and nozzles.

“Without adequate coarse filtering of process fluids, oil and gas systems can be susceptible to expensive damage from large particulates,” says Glenn Mountain, General Manager at R.P. Adams, a Buffalo, NY-based manufacturer of industrial filtration equipment. “Raw or produced water that is not adequately pre-filtered can cause excessive fouling, leading to decreased production as well as costly, premature replacement and unscheduled production downtime.”

Fortunately, a growing number of oil and gas industry professionals are ensuring more reliable production with superior water or process fluid quality by using low maintenance, multi-element, automatic self-cleaning strainers. This approach provides a more effective first line of defense against equipment damage and downtime.

Optimizing Process Reliability and Production

Historically, the oil and gas industry has utilized certain types of sand or media filters, centrifugal separators, and basket type strainers for coarse filtration. However, in many cases these have a number of shortcomings, including susceptibility to fouling and damage, which can require frequent cleaning, maintenance, and early replacement.

“Whether for upstream or downstream processes, the industry wants to keep production going 24/7,” says Mountain. “So, the goal is to avoid equipment damage, process interruption, and having to pay maintenance technicians to open up filters for cleaning when they get dirty.”

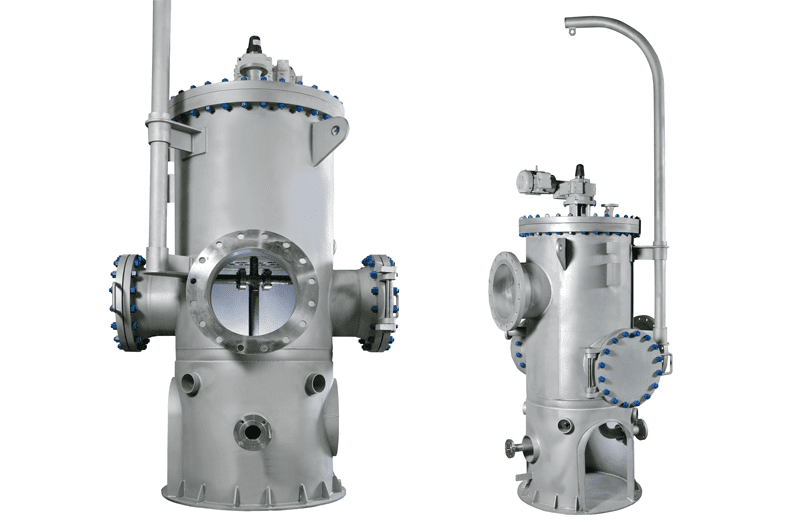

In response, many oil and gas industry professionals now rely on multi-element, automatic self-cleaning strainers like those from R. P. Adams. The company first introduced and patented the technology in the 1960s, and has over 10,000 installations worldwide today.

This design provides an alternative to sand and media filters, centrifugal separators, and basket type strainers. Unlike those designs, the multi-element, automatic self-cleaning strainers can provide continuous removal of suspended solids. When utilized as the “first line of defense” for oil and gas water or fluid filtration, the strainers can reliably filter out sand, silt, and other suspended solids as small as 30-100 microns in size.

A significant feature of the multi-element design is in the engineering of the backwash mechanism, which enhances reliability. With many traditional strainers, the backwash mechanism comes into direct contact with the straining media. This can be problematic, as large, suspended solids often encountered with raw or produced water can become lodged between the straining media and the backwash assembly. The result is straining media damage and/or rupture that can compromise filtration and even other downstream equipment, hindering production. Instead, the multi-element design utilizes a tube sheet to separate the straining media from the backwash mechanism. This prevents the backwash mechanism from coming into contact with the media and damaging the elements.

Oil and gas industry operators often also need to consider how to best reduce membrane fouling and required maintenance. Traditional strainers, however, due to limitations in straining area can become clogged quickly. When that occurs, cleaning, media replacement or backwashing is necessary, which adversely affects productivity as well as maintenance costs. In this regard, the multi-element design provides three to four times the surface area of traditional strainers and pre-filters. This translates directly into less frequent backwashing so less water goes to waste, less power is consumed, and less maintenance is required.

While traditional media found in large basket designs can lead to collapse and failure under differential pressures as low as 35 PSID, the smaller diameter of the media used in the multi-tube strainers also enables the strainer to safely handle differential pressures in excess of 150 PSIG. This protects production even under higher differential pressures in the field, which could otherwise result in significant downtime.

As an additional protective measure, the strainers also include a shear key, which sacrifices itself in the presence of excessively large debris. So, if large debris were to cause mechanical problems within the strainer, the shear key breaks, protecting the unit’s rotating assembly, motor, and gearbox by halting the drive shaft rotation. Filtration continues, but operators notice an increase in differential pressure as the backwash cycle is interrupted, and can take action to clear the obstruction and replace the shear key.

For oil and gas environments exposed to highly corrosive elements like seawater or salt spray, upgrade options to materials such as super duplex and duplex stainless steels, titanium, Monel, Inconel, and Hastelloy can also provide further resistance to corrosion and corrosion-related damage.

When considering technology for oil and gas course filtration systems, automatic multi-element, self-cleaning filters are an increasingly popular choice and a reliable, cost effective solution.

Del Williams is a technical writer based in Torrance, California.