The oil and gas industry has quickly made leaps and bounds in combatting COVID-19, and the offshore sector has been forced to develop creative and innovative tactics in winning the battle. Like the various types of work that make up the shale industry, the offshore world serves as the workplace for many, but is also taxed with having to create a safe living environment in addition to a safe working environment. The once commonplace activity of managing shifts for 24-hour operations and extended schedules has quickly become a logistical nightmare.

An incredible amount of time and effort goes into scheduling offshore work and ensuring living space is available, most often described by a term known as “Persons Onboard” or POB. With the current standards and guidelines of social distancing and strict hygiene orders, providing a safe working and living atmosphere has monopolized the attention of many companies. Limiting personnel in living quarters on an offshore facility results in a decreased size in workforce.

Headquartered in Louisiana, LLOG Exploration is a deepwater operator in the Gulf of Mexico and has faced the challenges of COVID-19 head on. According to LLOG geologist, Eric Zimmermann, the company’s approach in dealing with the virus originated with adhering to the guidelines authored by federal and state-run organizations and agencies in the know.

“LLOG’s course of action is in line with the CDC,” said Zimmermann. “We are also following those guidelines of the Louisiana Department of Health and we’re partnering with our telehealth providers.”

Although LLOG is not quarantining workers going to their offshore sites now, it has exhibited ingenuity with the precautions currently in action. Rotations known as “hitches” have been extended to decrease the workforce’s exposure to potential outside contamination. When maintaining health offshore, limiting ingress and egress with land is crucial. Keeping the working population isolated allows for the ability to only be concerned with controlling a potential outbreak offshore.

“Limiting contact is a huge defense,” said Zimmermann. “We’re prioritizing work to be done. If it can wait, then it is postponed for now. We are also conducting a screening process of checking temperatures and if any COVID symptoms are presenting themselves.”

Other companies offshore have adopted this postponement of work practice and while it is agreed necessary, it has wreaked financial havoc on some service providers in the industry. Coupled with the decline in oil prices, the pandemic has greatly affected the financial bottom line of many.

“We have seen a significant decrease in earnings,” said Mike Bethea, CEO of Offshore Technical Compliance LLC, an offshore service provider.

The COVID-19 pandemic is widely considered a fluid situation and information is continually changing. Zimmermann said LLOG conducts bi-weekly meetings dedicated to steering the company’s response.

“The pandemic is dynamic and a top concern for us.” said Zimmermann.

Offshore service providers have also had to develop their own COVID-19 action plans to protect their employees, but also due to the requirements implemented by companies like LLOG. These partnerships have not only increased awareness, but they have also attempted to tip the scales in a positive direction specifically with limiting the number of COVID-19 cases experienced.

Headquartered in Louisiana, Offshore Technical Compliance provides a variety of services including digital pressure testing. In addition to other services offered, it conducts work on major offshore facilities and for many different companies. According to Bethea, major E&Ps and operators want assurances that companies such as his have pandemic preparedness plans in place to prevent individuals, who are potentially infected with the virus, from showing up at heliports and docks. In fact, this practice is widely represented by third-party management systems, such as ISN and Veriforce, where the pandemic preparedness plan must be uploaded to the system to provide validation and verification to the customer.

All members of the offshore community are concerned with the general health and safety of every person on the facility, but additional factors are in play as well.

“The impact of a positive test offshore is extremely costly,” said Bethea. “A variety of policies have been implemented by our customers to ensure safety and decrease the possibility of additional costs.”

Bethea noted that early check-ins have yielded positive results with workers quarantining prior to going offshore. This is an increase in costs; however, it is proactive behavior that can assist in keeping the infection rate to a minimum, if at all.

Although most of these new procedures and policies are costly, deepwater companies are not shying away from providing them. Zimmermann stated that LLOG is committed to medivac quickly, if needed, to remove workers from a facility should they display COVID-19 symptoms.

In addition to the new and challenging logistics of working offshore, the customers and contractors share another issue. Both have employee teams that reside on land and support their offshore activity. They are, therefore, tasked with ensuring safe working environments in their own offices as well as for those working offshore.

“Our office is on a platoon system and we are staggering work times,” said Zimmermann. “We have instituted a no-touch policy and we have a team that cleans our facility daily. Masks are also required in all communal areas of our offices.”

Bethea stated his company’s office response is in line with agency regulations. Staff is limited to no more than ten people in the office at a given time and must practice social distancing. Staff members who are not in the office have the capability to work from home.

“Our employees are required to wear masks when entering our building, but can take them off when they reach their individual office spaces,” said Bethea. “If a person does not feel well, we want them to stay home.”

Bethea feels Offshore Technical Compliance’s vigilance has played an important factor in why it has experienced no cases of COVID-19 on a company level. Disinfecting protocols have been instituted in its offices with a professional service cleaning the facility twice a week. Food must be closed and sealed, and hand sanitizer stations have been staged at commonly touched surfaces. Office personnel have also been tasked with cleaning and wiping surfaces in their personal workspaces.

Because COVID-19 directly affects all aspects of business, offshore companies have been forced to change their thinking and how they can adapt to the new normal. Task forces and special committees are being devised to meet business needs. Zimmermann indicated that LLOG’s HSE staff is leading its offshore efforts and staying educated with the virus’ changing effects.

Bethea said that Offshore Technical Compliance’s management team is monitoring its response globally as services are provided on an international level. He explained that it is challenging because, in addition to the federal and state guidelines revolving around COVID-19, the company must also follow the guidelines of other countries where its services are provided.

“We have a relationship with a management company in Mexico that helps us over there,” said Bethea. “That company is bilingual.”

Considering that, as of this writing, the U.S. appears to be witnessing an increase in COVID-19 positive cases, many offshore companies have been looking to the future and attempting to establish protocols to deal with the pandemic for an extended period. According to Zimmermann, LLOG is meeting regularly to examine information and plan for potential strategies needed for the company to coexist with the virus.

Bethea said that Offshore Technical Compliance is relying on innovation to shape any needed strategies. The company is investigating bundling services to be competitive and is focusing on global markets where it is not as simple to cease work.

Speculation over how conducting business may be forever altered after COVID-19 has run its course has plagued the offshore industry. With reports of increased numbers in positive cases, as well as the possibility of vaccines on the horizon, one question is continually repeated: Will the pandemic leave behind lasting effects that will permanently change the business models of offshore companies around the globe?

“It is a little early to tell what the post-COVID world will look like, but we have aggressively acted to get our digital communications platforms to a high level,” said Zimmermann. “This utility will certainly be a centerpiece to how we do our business in the future.”

Zimmermann added that many adjustments will be made and that teleconferencing has been invaluable. He indicated that the capability to share a screen has been a very useful feature during those teleconferences. He also said he envisions corporate travel being streamlined.

According to Bethea, he sees many tactics remaining in the workplace. Practices such as distancing when possible and hand washing should be remaining in use as needed. He feels the pandemic has revolutionized how the world uses the telephone and foresees video conferencing being the primary form of communication. He is also convinced that remote working will be regularly instituted in the workplace.

“One thing we have learned from this pandemic is to be flexible,” said Bethea. “We will be better prepared in the future.”

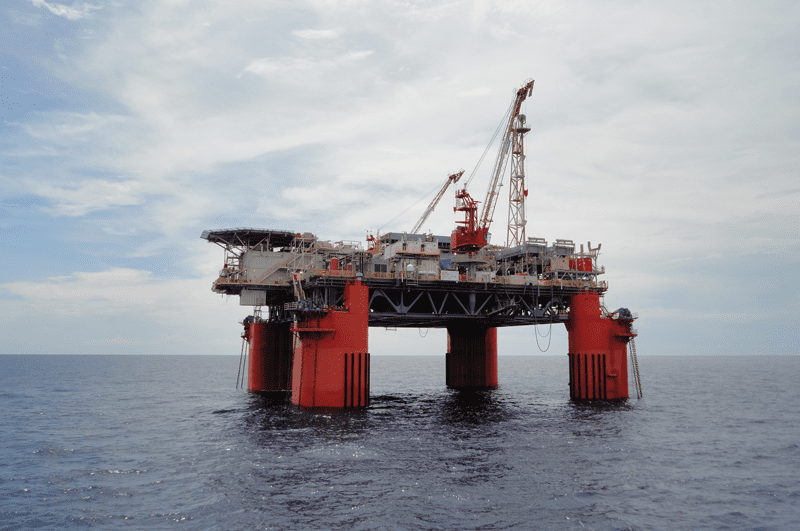

Headline photo courtesy of LLOG Exploration: LLOG Who Dat Production Facility

Nick Vaccaro is a freelance writer and photographer. In addition to providing technical writing services, he is an HSE consultant in the oil and gas industry with twelve years of experience. Vaccaro also contributes to SHALE Oil and Gas Business Magazine, American Oil and Gas Investor, Oil and Gas Investor, Energies Magazine and Louisiana Sportsman Magazine. He has a BA in photojournalism from Loyola University and resides in the New Orleans area. Vaccaro can be reached at 985-966-0957 or nav@vaccarogroupllc.com.