From Paper Records to Digital Checklists and Digital Twins and an Electronic Ecosystem to Prevent the Next Macondo

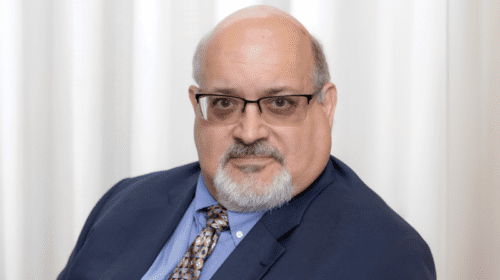

April 20, 2010: Mike Fry recalls that fateful night – “I was the Subsea superintendent for Transocean. I helped support several of our GoM deepwater fleet from a Subsea operations standpoint and technical field support. The Deepwater Horizon was one of them. So, on the night of the incident, I got a telephone call basically asking where the control system drawings were, and obviously, I knew that something was wrong because that would not be a call that I would get at basically about 10:30 at night.”

But then when Fry asked what was wrong, they just said, “Hey, don’t worry about it at the moment. Go back to bed.” He scrambled out of bed and called and e-mailed the rig. No response. Then he sent an e-mail to the rig manager in Houston saying, “Hey, I got this really cryptic telephone call, what’s going on? Is there anything I can help you guys with?” They responded quickly, “Hey, Mike, you need to get to the office as quickly as possible, can’t discuss anything more about it.”

As Fry raced for the Transocean office he wondered “what could be that severe that they won’t give me any information” and imagined different scenarios. But nothing could have prepared him for the USCG satellite images taken from space. The Deepwater Horizon MODU was burning with flames shooting 200 feet through the derrick. He had worked with six of the eleven men who died that night. He was also close to some of the 63 men and women who are still going through surgeries today. For the next 86 days he would live in the BP Crisis Center taking 12-hour shifts as the best and brightest engineers and scientist on the planet worked to cap the well on July 15, 2010. Macondo was the offshore oil and gas Industry’s Apollo One. The goal in 2020 is to prevent a Challenger or Columbia type disaster.

Fry says every week he is still asked if Macondo could have been prevented. He says, “unfortunately, the question he still gets is always from an operational standpoint if the things that went wrong, not counting the BOP, if we did the exact same thing over again, could Macondo happen a second time?”

“Unfortunately, the answer is yes because it had nothing to do with the blow-out preventer. Investigations proved there were so many things that went wrong that if we did it all over again, the exact same steps with the new regulations in place, it would happen again,” Fry says.

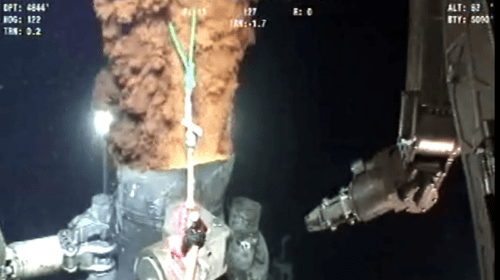

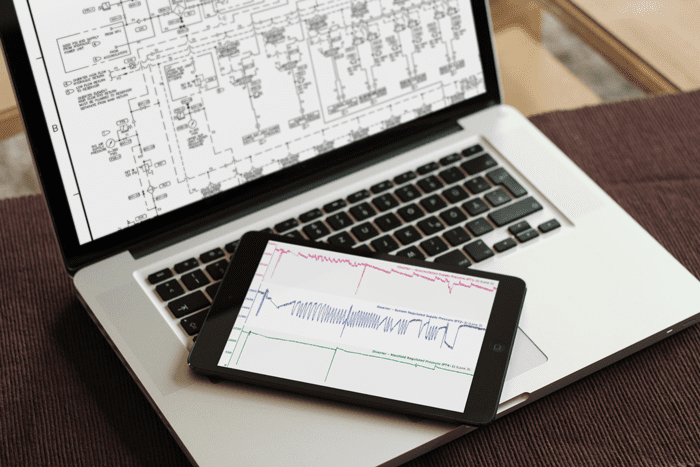

Like an EKG – it creates a digital fingerprint of every minute of the BOP and riser equipment. Evidence for

the regulator, operators and drilling contractors of procedural compliance. Photos courtesy of Mike Fry

Even in 2019 he gets questioned about the cost and the ROI. When potential customers asked him why they should invest in a digital checklist and ecosystem to provide evidence that procedures are followed 100 percent of the time his memories of those lost on the night of April 20, 2010 lead him to speak from the heart: “It’s like, guys, Macondo was really only nine years ago. Are we going back in the other direction again? I understand what’s right, but cost is now coming back into the forefront, right? So, how do you eliminate a Macondo from happening? Operationally, you really have to have organizations where the human factor of peer pressure and outside influences get removed, and it just comes down to procedural discipline and doing what needs to be done, WHEN it needs to be done simply because this is the way that we do business, these are our policies and procedures, and we’re going to follow them to the letter of the law, and we’re not going to deviate because of management pressure to try to speed things up. We’re going to do the things the way they need to be done, and just execute it safely, and move onto the next job,” Fry says.

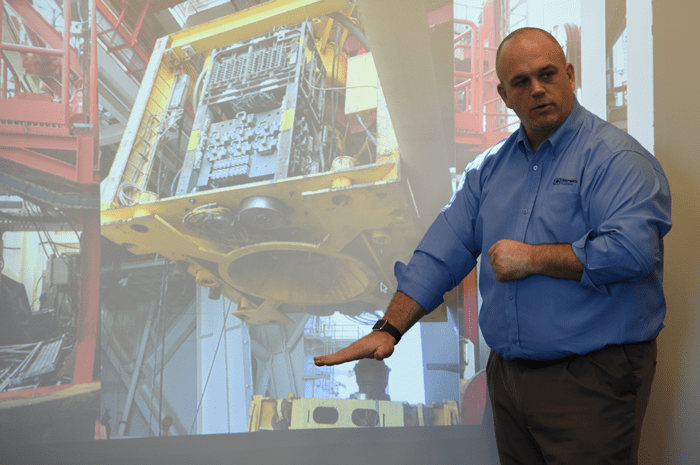

In 2014 while working in the corporate office for Vantage Drilling still remembering Macondo, Fry had a moment that led him to make a life changing decision. He decided he could continue trying to change his company or walk away and start his own company with the mission of changing the global drilling industry. He picked the latter option. By 2015, Deepwater Subsea opened in Houston offering IADC accredited Deepwater Subsea Management Training which involved white binders with all the API and BSEE regulations and the Microsoft Suite for creating a more streamlined approach for operation project management and daily tracking of BOP and riser systems. Those courses spun into quality assurance and leadership courses and providing audit services for his clients around the globe.

When BSEE unveiled the new well control rules in 2016 Fry became convinced that paperwork might be a cause of procedural drift and in people not performing the required tasks. He dreamed of putting the procedure checklists on an iPad or laptop. He reached out to software companies, “They all said give me six figures and six months.” He dreaded having to communicate to a software vendor what it had taken him more than two decades to understand.

Throughout 2016, Deepwater Subsea began signing up clients to do their annual compliance audits and as he traveled around the globe, Fry realized the global deepwater drilling industry needed an innovative approach to capture all the data collected minute by minute that would leave an electronic ledger of every action taken, photos of the equipment, something beyond an electronic tally book on when a problem was spotted and the response onshore and from OEM. Total transparency could prevent near misses and also provide a method for reporting every detail.

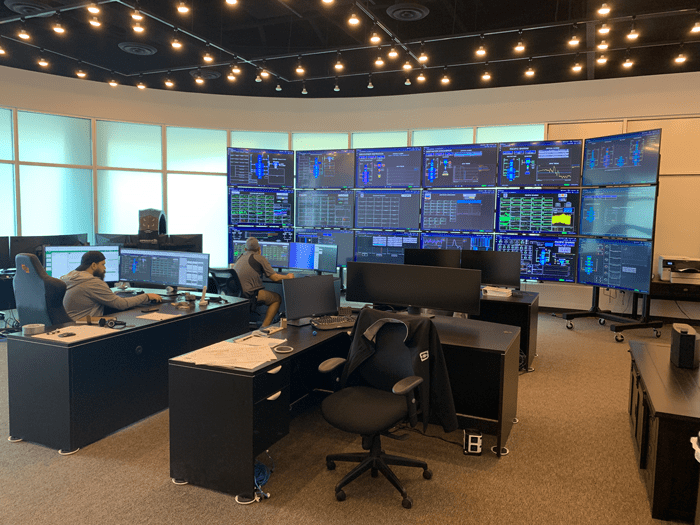

In March 2018, Fry attended a conference and met the folks from J5 International. He says it was the quickest deal he ever consummated in his life. Everything he had been hoping for and dreaming about fell into place. With the addition of new software, he could lay out all the information in much the same way he had learned to do with Microsoft Office and using Google Docs. J5 allowed adding the digital twins for the BOPs of his clients and the creation of the 24/7 real time monitoring system center for all the BOPS he had contracts to service.

In 2019, Fry added Hexagon’s SDX platform. The Hexagon and J5’s operational management system can pull information from the OSIsoft PI system and it can also write back from the IndustraForms, back into the PI system. The Hexagon’s SDX operational software allows the use of smart P&IDs, basically integrating with J5’s IndustraForms, and also pull PI system data.

As the Deepwater Subsea Digital Ecosystem combining multiple software and AI solutions, customers and drilling contractors expressed excitement over finally having minute by minute legal proof of procedural compliance.

But when Fry started rolling out the program to his team and the workforce he was faced with hostility. Even though many had grown up with Xboxes and playing video games, they instantly wondered why they needed Big Brother tracking everything they did each day. They expressed shock at not being trusted. The post Macondo paperwork took so much time away from the actual work and had been overwhelming but they feared the digital system would just make their job even more challenging.

Change is painful and difficult. When his team and offshore workers asked him why he did not trust them, he realized implementing the totally digital ecosystem would take more than trust. He would have to provide a compelling and rational reason for the dramatic change in industry operations.

To allay fear of the digital system, Fry created roll-out classes on the new BSEE requirement for verifying procedural compliance. One of the points Fry shared in class, “When the BSEE inspector arrives at your rig you will have to verify and show how you documented the process, and show the documentation we use for verification. This digital checklist allows a BSEE inspector who is digging deeper to find everything in less than five minutes. The digital checklist is protecting each of you and all of the companies involved to identify the small before they become an insurmountable crisis.”

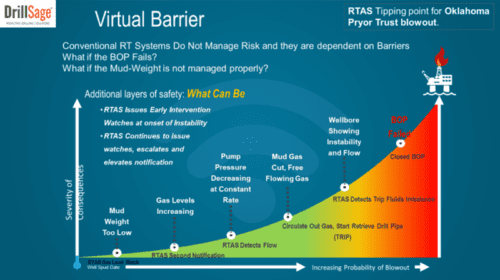

Fry says the ecosystem is great for overall subsea operation, but perhaps the biggest change from ten years ago is the ability to troubleshoot: “When the alert goes to the Janus24 monitoring center in Houston, the team on duty calls the rig to inform them of the event.” Fry says with the click of a mouse the team can pull up the digital BOP while the ROV is flying down and can get a 3D image of what the camera on the ROV will be showing. It might take the ROV five hours to reach the seabed. With a few more clicks the Deepwater Subsea team has all the information needed to share with the client and with the work crews and ROV operator. “The client, drilling contractor and all stakeholders can see what is happening in real time almost as though we were visually inspecting the BOP from the seabed,” Fry says.

Lillian Espinoza-Gala, owner LEG Exploration Education, served on the steering committee for National Academy of Science Offshore Worker Empowerment workshop held in Houston in January 2018 and a section of her Macondo Research is published in Chapter 2 of the proceedings. She currently serves as a Membership Chair on SPE International Human Factors Technical Section Board.