While the oil and gas industry may fluctuate, the presence of drilling waste remains consistent – as does the need to dispose of that waste. Operators are often on the lookout for innovative ways to handle, treat and even reuse waste from oil and natural gas drilling processes.

Drilling mud, also known as drilling fluid, is one of those common wastes and an essential component of the drilling process. In oil and gas drilling operations, drilling muds are used to control subsurface pressures, lubricate the drill bit, stabilize the well bore and transport drill cuttings to the surface.

During the drilling process, boreholes are created in the earth. Those holes are drilled for the extraction of oil and gas, as well as for core sampling and other purposes. Drilling mud aids in the borehole drilling process by acting as lubricant for the drill bit while also transporting drill cuttings – another form of drilling waste – to the surface. Drill cuttings are broken pieces of solid material that are created as the drill bit penetrates and breaks the rock. As the drilling mud circulates up from the drill bit, it carries the drill cuttings up to the surface, where the mud and cuttings must be separated before recovery.

Thermal treatment presents operators with the opportunity to remediate and reuse drilling wastes. With the use of a thermal desorption unit, drill cuttings and drilling muds can be treated for beneficial reuse.

Types of Drilling Mud

Depending on the application, one of three types of drilling muds may be used: water-based muds (WBMs), oil-based muds (OBMs) or synthetic-based muds (SBMs). OBMs are one of the most effective drilling fluids, but many wells, especially in the southern gas basin of the North Sea, are drilled with WBMs. SBMs have a lower environmental impact and biodegrade more quickly, making SBMs one of the more frequently used types of drilling fluids.

WBMs are produced with water mixed with clays and other chemicals to create a homogenous blend and generally consist of bentonite clay with additives, such as barium sulfate, calcium carbonate or hematite. Thickeners, such as xanthan gum, glycol and starch, may also be used to influence the mud’s viscosity.

OBMs have a base fluid consisting of a petroleum product. Because of their increased lubricity, enhanced shale inhibition and greater cleaning abilities, OBMs are more frequently used than WBMs. OBMs are also able to withstand greater heat without breaking down.

SBMs possess a base fluid of synthetic oil. These muds are most frequently used on offshore rigs because they have the same properties as OBMs but a toxicity of fluid fumes that is significantly lower.

Drilling Waste Disposal and Recovery

After the drilling job is complete, the drilling wastes must be disposed of in some way. The U.S. Environmental Protection Agency classifies drilling fluids as “special waste,” meaning that they are exempt from many federal regulations. Because of that classification, laws governing the disposal of drilling muds vary from state to state. In California, for example, the state government has a strict set of regulations for drilling wastes and requires operators to obtain approval before they may begin any type of disposal.

In 2012, an oil company in Texas had to pay a $1.35 million fine after drilling waste that was placed on their “landfarm” contaminated nearby water sources. Landfarms are privately-owned, state-regulated fields where drilling waste is spread. While they are legal, they are capable of causing damage to the surrounding environment. Drilling waste, even when buried, can easily contaminate soil and groundwater when the hydrocarbons and other chemicals leach into the earth.

While most WBMs are disposed of when the drilling job is completed, many OBMs and SBMs can actually be recycled. Drill cuttings can also be recycled and reused after the hydrocarbons are removed.

On a standard drilling rig, there are a variety of relatively simple processes that can be used to capture clean mud that would otherwise be discarded and put it to beneficial reuse. Throughout the drilling process, for example, drilling fluids are recirculated, which aids in decreasing waste by reusing as much mud as possible. Even the recovery of drilling fluids during tank cleaning may present an opportunity for reuse.

Drilling mud transports the drill cuttings back to the surface in order to prevent the well from clogging. On the drilling rig, the cuttings are separated from the mud, and the mud is recycled for reuse. The drill cuttings, meanwhile, are either discharged to the seabed, re-injected into the well or taken ashore for treatment and disposal. Those cuttings vary in size and texture, depending on the type of rock and drill used. Drill cuttings can range in size from fine sand to gravel.

While drill cuttings are often disposed of after the drilling operation is finished, they can actually be treated and beneficially reused. Before drill cuttings can be reused, however, it is necessary to ensure that the hydrocarbon content, moisture content, salinity and clay content are suitable for the cuttings’ intended use.

There are numerous applications for recycled drill cuttings, such as the stabilization of surfaces that are vulnerable to erosion, like roads and drilling pads. Oily drill cuttings can also serve the same function as traditional tar-and-chip road surfacing. Cuttings can also be used as aggregate or filler in concrete, brick or block manufacturing, as construction material or as daily cover at landfills.

Recycled cuttings may also be used in the production of cement. Research has even been done on additional uses for recycled drill cuttings. There have been trials conducted in the United Kingdom to determine the feasibility of using oily drill cuttings as fuel for power plants. In the U.S., the Department of Energy has researched the possibility of using drill cuttings as a substrate for restoring coastal wetlands.

Thermal Treatment of Drilling Wastes

The best method for unlocking all the potential uses of drilling wastes is through thermal treatment technologies, such as thermal desorption. Through the use of extremely high temperatures, thermal treatment reclaims or destroys hydrocarbon-contaminated materials, such as drilling wastes. Thermal processes are the most efficient treatment for destroying organics, capable of reducing the volume and mobility of inorganics, such as metals and salts. Waste streams that are particularly high in hydrocarbons, such as OBMs, are excellent candidates for thermal treatment.

Thermal treatment may be a short-term process to reduce toxicity and volume, as well as prepare waste materials for further treatment and disposal, or it may be a final treatment process, resulting in inert solids, water and recovered base fluids. Through the application of heat, thermal desorption vaporizes volatiles and semi-volatiles and easily removes light hydrocarbons and aromatics. The process produces a variety of secondary waste streams, including solids, water condensate and oil condensate.

Rotary kilns and hot oil processors are the most frequently used equipment and most proven methods for the thermal desorption of drilling wastes. Indirect fired rotary kilns use hot exhaust gases from fuel combustion to heat drilling muds and drill cuttings. This type of kiln consists of a rotating drum placed inside a jacket. Heat for the process is provided through the wall of the drum by the hot exhaust gas that flows between the jacket and the drum. The drilling wastes are transported through the drum as it rotates, and the treated solids are recirculated to prevent a layer of dried clay from forming inside the drum.

A vapor recovery unit can be used to recover or condense hydrocarbons from the gas stream extracted out of the thermal desorption unit. The hydrocarbons are not destroyed but may be reused in the process as an alternative fuel source or sold as a by-product. Vapor recovery units consist of a quench scrubber, mist eliminator, shell and tube heat exchanger, knock-out pot, oil/water separator and pre-combustion chamber. Depending on the process and material, optional items can be added to the process, including baghouses, thermal oxidizers or acid scrubbers.

Indirect fired thermal desorption systems are available that can process up to 10 tons of material per hour and direct fired systems can process up to 40 tons per hour.

Testing services are available that offer a direct-fired and an indirect-fired rotary kiln for feasibility testing for thermal processes. Whether a company is expanding its inventory, researching new applications or testing efficiency, those testing services can help determine a complete solution for a company’s unique operations. Experienced operators work in conjunction with process engineers and clients to produce accurate, scalable and repeatable results.

Certain pilot plant options include a direct-fired rotary dryer or an indirect-fired rotary kiln with configurable air pollution control devices. A variety of thermal processes have been tested, including mercury removal from cement kiln dust; the drying of automotive shredder residue, limestone and bakery wastes; and the recovery of oil vapors from petroleum-contaminated soils. The testing results are confirmed by a third party laboratory for fast, reliable results. Continuous emission monitoring services are available in advance for monitoring of NOx, SOx, CO, PM, THC and other pollutants to ensure the systems meet government pollution regulations.

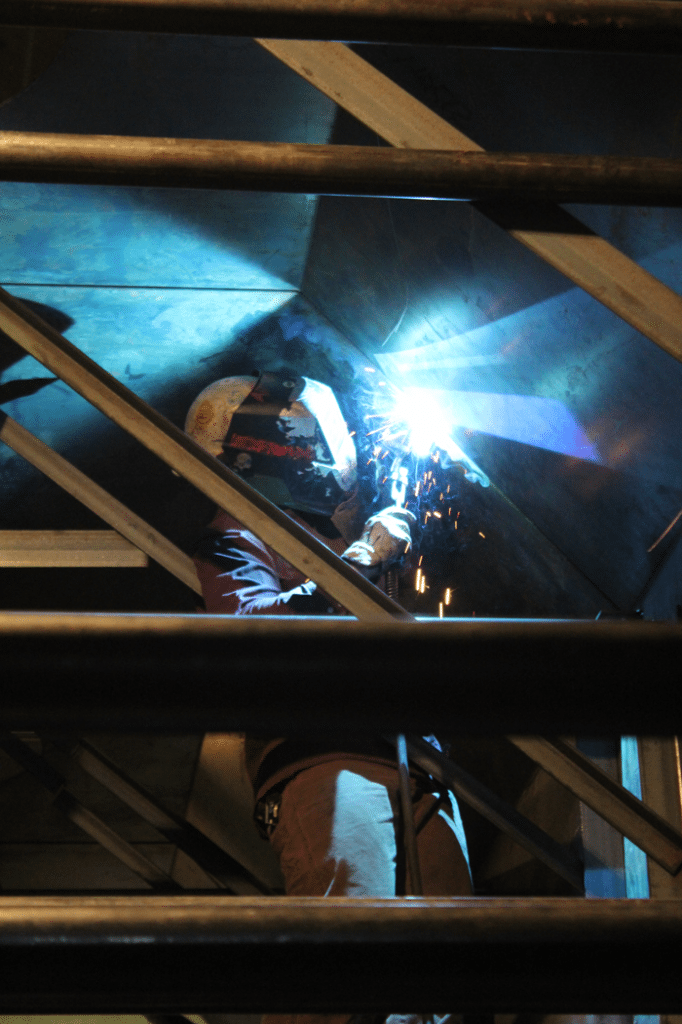

Full engineering design services are available that include Basis of Design documents, process flow diagrams, material energy balances, P&ID, electrical schematics, ASPEN simulation and detailed design drawings. Engineering design services, in conjunction with project management services, ensure that thermal solutions are appropriately sized, delivered on time and within budget.

Systems can be commissioned prior to shipment or on a company’s site. The company has the option of attending a commissioning test or requesting a live-streaming demonstration of the test. Live-streaming demonstrations present companies with the opportunity to view equipment tests from anywhere in the world via an internet connection.

Experienced operators can visit a company’s site and supervise the set-up process, as well as commission the system. Training also is available in material handling, thermal system configuration and maintenance.

Thermal Desorption Units

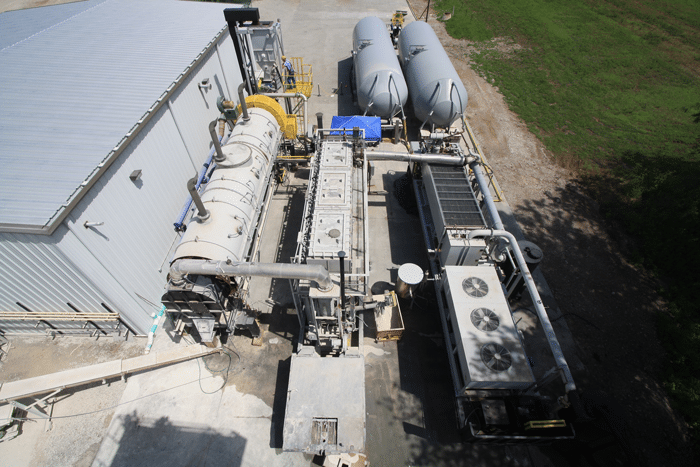

The indirect-fired thermal desorption unit is available as a six-foot diameter by 35-foot long heated zone 304 stainless steel rotary kiln with combustion chamber. The system is specifically designed to remediate soils and drilling muds contaminated with petroleum hydrocarbons. It consists of a primary treatment unit, quench scrubber, knock-out pot, oil/water separator, secondary treatment unit, air-cooled helical rotary liquid chiller induced draft fan, discharge system and control room.

In the process, the drilling mud is transferred to the feed hopper of the primary treatment unit (PTU) with the client’s backhoe or skid loader. The material is then fed to a feed hopper mounted on a pugmill. From the pugmill, the material is transferred to the feed auger, which conveys the drilling mud into the PTU and maintains a seal/airlock for the system.

The indirect-fired rotary kiln has three heat zones, and the operating temperature of the drum can reach up to 950 degrees Fahrenheit (510 Celsius). The rotary kiln is housed in a combustion chamber with six 2.7 MMBtu/hour burners, producing a total of 16.2 MMBtu/hour of heat. The kiln operates in an oxygen-deficient and slightly negative atmosphere. Vapors from the contaminated drilling muds are pulled out of the system in a countercurrent direction to the material flow.

The vapor from the PTU is pulled into a high-efficiency quench scrubber that uses oil as the quench liquid. The quench operates at 250 degrees Fahrenheit (121 Celsius) and removes dust particulate, in addition to condensing the heavier hydrocarbons in the vapor stream. The condensed oil and sludge are pumped through a set of filters to an oil/water separator and then to an onsite storage tank that is supplied by the client.

The vapor that is not condensed in the quench scrubber is pulled through the knock-out pot, the custom-built vertical helical heat exchanger, which reduces the temperature to 70 degrees Fahrenheit (21 Celsius). The fluid from the knock-out pot – condensed water and oil – is pumped to an oil/water separator, then to a water and oil holding tank that is supplied by the client.

The non-condensable gases are pulled from the knock-out pot by an induced draft fan and pushed into the secondary treatment unit, where all remaining hydrocarbons are destroyed at temperatures of up to 2,000 degrees Fahrenheit (1,093 Celsius) with a residence time of up to two seconds.

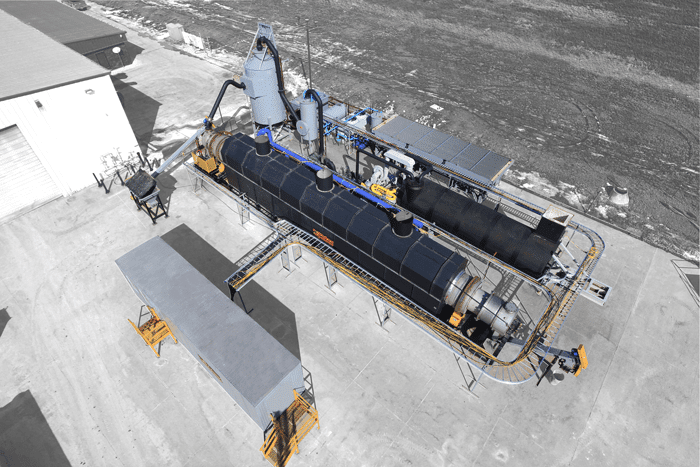

A compact mobile thermal desorption unit is available as a one-ton per hour indirect thermal desorption system designed to remediate drill cuttings. This compact, mobile unit provides thorough remediation of drill cuttings contaminated with petroleum hydrocarbons. Optional components, including acid scrubbers and a flameless electric thermal oxidizer, may be added to the system for an additional cost.

Recovering drill cuttings and drilling muds is often a practical and cost-effective environmentally sustainable process. Recycling and reusing drilling wastes can help operators meet disposal regulations, reduce disposal costs, limit truck traffic and save money on building well pads and roads. The proper disposal of such wastes prevents the contamination of water supplies and the soil. Thermal treatment of drill cuttings not only reduces their volume but also enables operators to recover reusable drilling fluids, resulting in significant cost savings while also augmenting environmental performance.

Savannah Cooper is a representative of Worldwide Recycling Equipment Sales, LLC, a major equipment manufacturer and dealer of recycling and environmental equipment. For more information on Vulcan® Systems, visit www.getavulcan.com, or contact Worldwide Recycling Equipment Sales, LLC at (660) 263-7575 or wwrequip@wwrequip.com.

Vulcan® Systems, formerly Worldwide Recycling Equipment Sales, provides custom-designed thermal processing solutions to clients in the oil and gas industry. For more information, visit vulcansystems.com or call 660-269-7502.