Digitalization in the offshore market has begun to ramp up, with new technologies poised to deliver substantial costs savings and improved profitability to the industry. However, these technologies depend on the existence of robust and reliable connectivity – a challenge for many offshore operators, particularly as they venture into deeper waters that are frequently out of range of traditional terrestrial networks.

Today, satellite communications are supporting rig and platform owners in powering an increasingly diverse range of applications while providing value and critical support to offshore businesses. High-quality, low-latency connectivity to offshore sites is enabling digital technologies such as real-time recording of field data, digital-twin, remote operations, which are all accelerated by the improved communications providing a major impact on operational efficiencies and crew safety.

The Connectivity Revolution

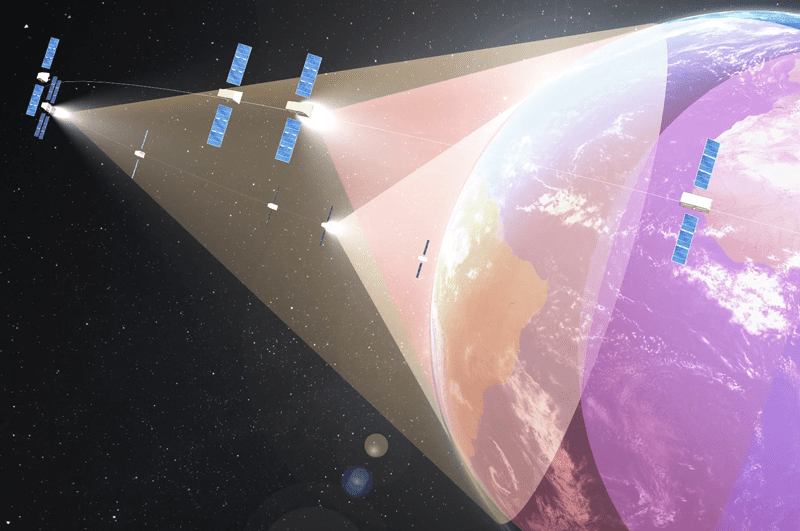

Until recently, the offshore industry was limited to the use of GEO (Geostationary) satellites for the transmission of data to rigs and platforms at sea that were beyond the reach of fibre or microwave networks. While GEO provides reliable and consistent connectivity, new digital applications leverage underlying technologies such as analytics, mobility and the cloud – technologies that rely on latency that is lower than GEO is able to provide.

The availability of the O3b MEO (Medium Earth Orbit) system in 2014 was a game-changer for the offshore industry. This constellation operates at a lower orbit than GEO systems, providing latencies of up to 150 milliseconds for a round trip data transfer, compared to almost 600 milliseconds per round trip for GEO.

The high throughput capacity and low latency of the O3b system opens the door to a range of digital capabilities that would not have been possible earlier, including applications such as real-time transfer of field data, virtual modeling of offshore assets and wireless sensor monitoring for better reservoir management, as well as IT services such as desktop virtualization, remote server access and cloud-based storage, with the end result being improved production and lower operating costs.

MEO-level latency and throughput enable an improved experience for crew wishing to remain entertained during their downtime and connected to family and friends while offshore – a key factor in the industry’s efforts to recruit and retain top talent.

Being the only satellite operator to offer both GEO and MEO high throughput capacity, SES combines the O3b MEO system with its wide-beam and high-throughput GEO assets to create an even more compelling value proposition for offshore operators, delivering network resiliency that is particularly critical for deep-water sites dependent on reliable connectivity.

Building the Path Forward

That high level of connectivity will become even more critical for the offshore industry as it adopts IoT and cloud. Sophisticated sensor technologies mean the OT (Operational Technology) realm is becoming increasingly connected, feeding critical data into onshore IT systems that previously operated as isolated business functions, while cloud computing platforms allow companies to more efficiently and cost-effectively process and analyze that data. The cloud also enables the cost-effective extension of onshore IT systems such as human resources, training and logistics to offshore sites, paving the way for safer and more efficient operations.

Cloud-optimized connectivity will be a critical part of that transformation, including strategic partnerships with leading cloud service providers. For example, SES has established these relationships, bringing the capabilities of the major cloud platforms such as IBM Direct and Microsoft Azure ExpressRoute to offshore sites. Cloud services can be provisioned over dedicated MEO or GEO links, or a combination of the two, delivering a tailored service with the latency, availability and coverage that is specific to the enterprise and application requirements, all backed by solid SLAs. The rollout of SES’s next-generation MEO constellation, O3b mPOWER, in 2021 will further strengthen the ability of offshore providers to capitalize on cloud services by delivering multi-gigabit, low-latency connectivity ideal for high-throughput applications and “bursty” cloud workloads.

Looking Ahead

Profitability and business continuity in the oil and gas sector will be inextricably linked to its adaptability and the tools that make it possible. High-speed, reliable and scalable connectivity solutions are crucial to enable the right set of applications that can fully digitalize operations. The next generation of satellite technology is essential to support the industry and open opportunities for its expansion and growth, while reducing complexity and risk. The demand for real-time data is growing, and it is critical that the offshore industry continues to keep pace, using the surging amounts of information to the best advantage for their individual operations.

Morten Hansen is responsible for the energy segment market management of SES Networks, a provider of global managed data services. He holds extensive experience in the remote communications and information technology services industries. He is currently leading the strategy, development, and positioning of products, services and solutions into the energy market vertical, including onshore/offshore oil and gas, resources/mining and related customer applications. Morten has more than 20 years of experience in information technology and telecommunications engineering, design and deployment, and is recognized as a visionary leader who can connect the gap between technology and monetization. He is also an Executive Producer for the award-winning film Zen Dog. Morten has completed an executive education course in customer-focused innovation at Stanford University's Graduate School of Business and holds an MBA from BI Norwegian Business School with specialization in energy.