Productivity, efficiency and precision are key components of success in the oil and gas industries. Being able to implement systems and offer tools to experts and business associates ensures that a team stays connected and works effectively. An important task on the oilfield is ensuring that a team of associates is well-trained and well-equipped to manage the demands and complications on the oilfield. As the need for skilled field workers increases, the need for competent professionals and on-site productivity increases as well.

Companies need their teams to show up at a location, understand the equipment, be confident that all is in good working order, and be able to perform effectively in the field for maximum efficiency.

Currently, many of the long-time oilfield workers are retiring, and there are not enough qualified candidates entering the field with proper hands-on training and experience. Electronic power tong test stands are now available that test hydraulic power tong equipment before it goes into the oilfield.

With a tong test stand, associates and experts are able to blend technology, communication, and equipment operation to eliminate downtime on a job site, speed productivity, and decrease monetary and time waste. It is much easier to troubleshoot and fix a problem at headquarters rather than when associates are on the field.

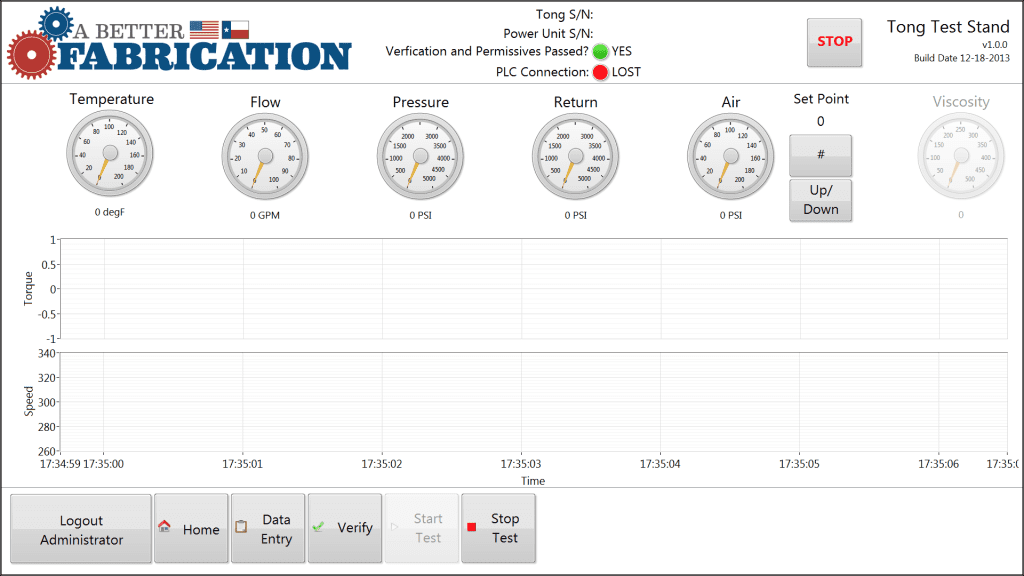

A standard test stand model includes:

- Torque

- RPM

- Hydraulic fluid supply and return pressures

- Hydraulic fluid temperature

- Storage capability for tong and power unit serial numbers

- Storage capability for downloadable session data for over 50,000 test sessions

- Dump valve for air and hydraulics

- Emergency diverter valve for catastrophic pressure loss

- Safety strobe

- Air regulator

The electronic power tong test stand acts as a training simulator for employees, and function-tests tongs and power units at every level. They are able to ensure that the equipment works well, taking care that associates on the field are well- trained on the equipment, while also learning to operate the tongs safely.

Top reasons to incorporate the electronic power tong test stand into associate training modules are:

- Train employees before going onto the job site

- Test a fleet of tongs before starting a project

- Prevent downtime on a well site

- Simulate make-torque and brake-torque

- Detect any problems before the tongs go into use

- Save time and money by testing equipment

- Integrate curriculum with the software for certificating employees with tongs

- Deployable in virtually any environment with industry-leading, worldwide recognized industrialized components

- Incorporate multiple safety features, including a Standard Safety Strobe, one-ton jib crane, torque assembly and air regulator

- Send diagnostics by email or through a network directly from the test stand

A training simulator also is available that works in conjunction with the testing equipment. Companies can not only function-test power tong equipment and power units, but also train associates to have a working knowledge of hydraulic power tong operations. By training a team ahead of a project start date, managers and customers can rest assured that workers are efficient and productive on-site.

The testing system integrates checklists, training and work processes, and collects necessary data digitally. The equipment is identified by its serial number, the power unit serial number, and the mandrel size being tested. Preliminary set-up and checklists are loaded, and the tests are performed. Once everything is in place and checklists are approved, torque is simulated. A test is marked “passed” if the desired torque is reached and no problems were incurred.

The data and tests can then be saved, certified, sent, and downloaded by experts and clients regardless of where they are located, making it possible to watch the testing progress from a remote office, clear any hazards, and put the platform in good working order after going through the checklists and steps to ensure safety.

Dearl Berrier is Head of Operations at A Better Fabrication LLC. He can be reached at 817-629-8908 or abetterfabrication.com.