XTO Energy holds the mineral rights on the property about 20 miles northeast of Watford City and is working with Houston-based Nabor’s Drilling to drill wells and extract oil and natural gas from the Bakken shale formation about 17,000 feet underground.

The oil and gas industry has invested large amounts of capital into efficiency, and rig assembly is just one of the examples of it paying off.

“A good rig move, assuming all the trucks and everything moves in a perfect world, will take about four days.” Olsen said. “We contract out the trucks and crane, but our crews do pretty much everything else.”

A well cycle operates in three phases – drilling, completion and production. The drill is surrounded by a sea of metal, machinery, computer monitors and safety signs. It is controlled in a nearby room by directional drillers, who monitor graphs and relay instructions to the driller. The driller, in turn, precisely controls the drill underground.

As the well is drilled, multiple layers of steel pipe, casing and cement are lined to separate the oil and gas. The well is equipped with a blowout preventer (BOP), which acts as a backup in case there are any issues in the process.

The BOP is a large, specialized mechanical device used to seal, control and monitor oil and gas wells. The BOP controls the extreme erratic pressures and uncontrolled flows or kicks emanating from the well reservoir. Additionally, the BOP controls the down hole pressure and flow of the oil and gas.

“Tyson and I have put the BOP together more times than I care to recall,” Nabor’s Greg Burquist, drill superintendent said. “The BOP is the fail safe device.”

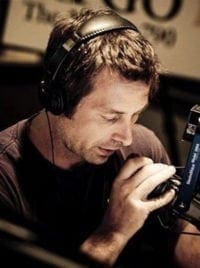

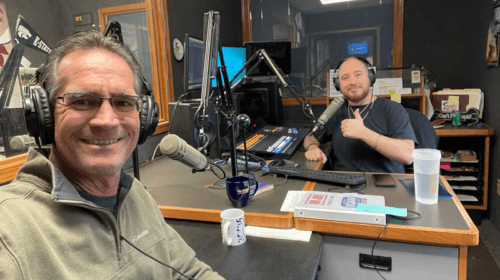

Jason Spiess is a multimedia journalist, entrepreneur and content consultant. Spiess has over 25 years of media experience in broadcasting, journalism, reporting and principal ownership in media companies. (Over 30 years experience if you count his adolescent years as a newspaper delivery boy learning the importance and logistics of daily distribution and monthly door-to-door bill collecting.) Spiess has worked in the areas of oil and gas, UAS and precision agriculture, health care, cannabis, agriculture, real estate, government affairs and economic development. Spiess is the host of two radio programs, Building the Bakken and Coffee & Capitalism, and three specialty programs, MonDak OilField Review, Corporate Ink and UnStuck, that carry a radio network that spans five states and two countries. Spiess is a North Dakota native and graduated from North Dakota State University.