In our increasingly connected world, portable gas detectors have been slow to keep up with the latest digital trends. In the age of IoT, you can control your toaster and home thermostat using an app on your smartphone, but what about your portable gas detector?

When wearing a portable gas detector on the job, whether it’s a single gas H2S monitor or a five-sensor multi-gas instrument, we really don’t pay much attention until the alarm sounds. This misses a trove of information about your work environment and your safety within it.

When a gas detector is paired wirelessly with a smartphone, usually via Bluetooth technology, you get access to so much more information. And better yet, you can easily share these data points with the rest of your team. Depending on your preferences, this exchange can even happen in real-time using a cloud-based portal.

Consider the smart watch. Popular health tracking apps allow you to review not only things like pulse, respiration, steps, calories burned, etc., but these activities are also placed in context, helping you make the most of this information. In addition to the time of day, the GPS feature shows you your location within a few meters, among a host of other parameters.

These digital devices are “always on,” which means they record information and observe their surroundings 24/7. If we apply the same approach to portable gas detection equipment, we could mine more information from our work environments. Whether at a particular job site or within a large plant, wouldn’t it be helpful to have consistent access to these data points? For example, if we consistently get elevated flammable gas readings near a building or piece of equipment, we can take proactive steps to improve worker safety.

When we add in the ‘connected’ gas detector, we are providing an entirely new level of context around the data provided by the instrument sensors. In order to display the insights available, gas detection equipment manufacturers need to develop a simplified user interface, while quickly disseminating data to those that need it most.

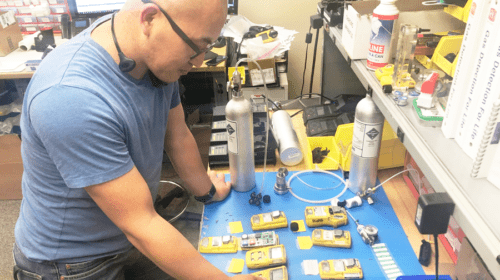

Docking stations for gas detectors are a common feature in industrial plants and refineries. They allow users to download data, charge the battery, and calibrate their instruments. These are necessary tasks, made easier by the semi-automatic nature of these devices. Depending on the instrument design, the docking station will be able to download ‘snapshots’ of the readings, alarms, bump tests, and calibrations. These may be minute-by-minute or at some other interval.

But what do we do with this information once we’ve gathered it? Many, if not most, docking stations are not integrated with a central database, let alone one that’s easily accessible. And while we don’t want to dismiss data security concerns, putting actionable data in the hands of safety professionals should be viewed as a priority.

Using a portable gas detector extends our senses, alerting us to dangers when they are present. As a tool, they are invaluable. The extended functionality of a ‘connected’ gas detector is right around the corner, with many elements already available. Developing a common platform for this data would be a major step towards widespread availability.

Photo above courtesy of PK Safety

Rick Pedley, PK Safety’s President and CEO, joined the family business in 1979. PK Safety, a supplier of occupational safety and personal protective equipment, has been operating since 1947 and takes OSHA, ANSI, PPE, and CSA work safety equipment seriously. PK Safety's customer service can be reached at 800-829-9580 or online at https://www.pksafety.com/contact-us.