In 2020, industry saw big, industrial operations truly pivot toward technology, as the growing demand for data, information and visibility has become amplified to the extreme. Simultaneously, we have seen the combination of a heightened awareness to safeguard employees and the need to deliver cleaner, greener supply chains. This perfect storm has brought asset performance management (APM) to the fore as a critical lever in both improving operations and mitigating the impact of detrimental issues.

The key driver behind APM is data democratization. Data needs to be channeled to the right people and areas of the business where the required analysis can be implemented. This process needs to be slick and seamless, so it’s unsurprising that businesses are now infusing this data with artificial intelligence (AI) to provide guidance and prescriptive action.

Optics optimization is the second driver. In essence, this is the continued optimization of balancing risk, cost and performance to ensure the right investment in an organization’s asset strategy. The final element, and perhaps the most important, is the workforce. Ensuring safety, while mitigating operational impact has been a fundamental challenge during the pandemic and one that will linger.

Strategize, Visualize, Realize

Strategy is fundamental to successful APM, including strategy of deployment, and where, how and why it sits within the entire operation. It informs investment decisions and ensures the right time and money are being spent on the right assets to meet corporate objectives, not to mention the return on investment informing other major business decisions around changing systems, processes and culture.

This is all supported with predictive analytics. This means leveraging advanced pattern recognition and AI to build up applications at scale, to turn insights into money saving opportunities. By identifying an anomaly before it becomes an issue, alongside providing remote guidance for correction, businesses are realizing incredible value.

Bringing People, Plants and Possibility Together

APM isn’t just a concept born to maintain operations during a pandemic. APM is a foundational technology that brings people, plants and possibility together to make the orchestration of operating and maintaining equipment that much easier and more effective.

This is something that will deliver value to businesses, long after the specter of COVID-19 has passed.

To learn more, visit https://sw.aveva.com/partners/microsoft.

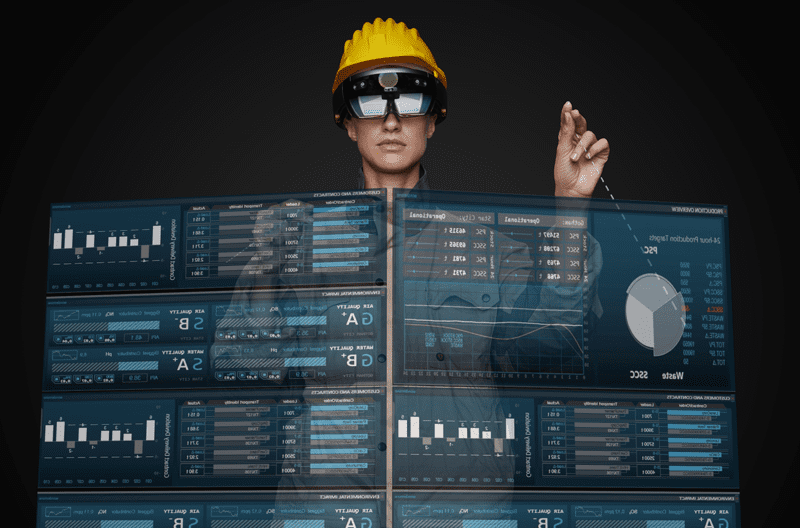

Headline photo courtesy of AVEVA.

Kim Custeau develops and leads the strategy for industrial asset performance management solutions that help AVEVA customers improve asset reliability and performance to maximize return on capital investments and increase profitability.

Custeau has 30+ years of experience in industrial asset management software and services. Prior to AVEVA, she was responsible for the strategic direction, commercialization and development of Schneider Electric Software’s asset performance software portfolio globally.

Her remit includes global responsibility for delivering solutions that help customers improve asset reliability and performance to maximize return on capital investments and increase profitability.