A Few Words on the State of the Industry

COVID-19 has turned the world upside down. If you are reading Oilman Magazine, then you, dear reader, know that the oil and gas industry is facing a major challenge. However, it is not like the industry has not been here before. As we all know very well, the oil industry is cyclical and world events, politics, and even global pandemics affect pricing and production, are the nature of this unique industry. We know that the industry will come out of this stronger, and ready to tackle new challenges that lie beyond the horizon. The 2014 downturn lead the industry to adopt more technology and improve efficiency. It will be interesting to see what new innovations the COVID-19 pandemic will bring to the oil and gas industry. While there is the burning question about how this will affect the companies we interview, we did not want to dwell on that in this interview, because we know very well that the industry will regain its momentum after this pandemic passes.

Chemical Tracer Technology

Oilman Magazine spoke with Tracerco, a part of Johnson Matthey, which specializes in innovative measurement services among other many other offerings. Tracerco provided us with insight into several of their technologies.

Tracerco offers well-monitoring services but what sets it apart is its use of liquid molecular tracers, which according to the company, “are able to fully quantify individual stage production without well intervention.” This makes it easier for production engineers to do their jobs. Tracerco went on to explain, “Quantifiable stage productivity data, when compared to drilling and stimulation decisions, provides the insight needed for effective field development. With this data, well landing, stage location, stage design, well spacing, and formation selection can all be optimized. Communication between wells is also measurable, providing insight into parent – child well relationships.”

Intrigued by the chemical tracer technologies, Oilman asked to take a deeper dive into the well of this technology. So, what are the primary advantages of chemical tracer technology? Tracerco answered, “Our chemical tracer technology eliminates the need to use expensive tools or wired systems to discover which part of a well is contributing oil, gas or water. With this information, we can establish clean-out effectiveness, water breakthrough and plug, packer or sleeve open or closed status.” It does this by fully quantifying the production contribution of oil, gas, and water over time. “This data can allow customers to compare actual stage tracer production results with pre-completion data, petrophysics, and geophysical expectations, as well as correlate between zonal productivity and drilling, stimulation, and production design to allow them to optimize field development strategies and maximize reservoir production.”

Subsea CT Scanner

If you were told that you could use a CT scanner to do subsea pipeline inspections, you might give the person telling you this a few odd looks. But yes, it is true! The CT Scanner DiscoveryTM was launched in 2013 and has completed close to 20,000 scans on more than 200 pipelines. While it is not new technology, per se, it is the world’s only field proven subsea CT scanner.

Adding more details, Tracerco said, “Unlike UT or MFL technology, DiscoveryTM can non-intrusively inspect complex subsea pipelines and pipeline systems without removing any of the protective coating. By doing so, it can quickly identify, determine and characterize integrity flaws, as well as flow assurance issues. This can all be achieved in real time, without compromising safety, stopping or interrupting production.” You can see why this scanner has completed so many scans in only seven short years. Might the industry see more of these scanners in the future?

Fuel Security Program

While fuel demand has waned greatly due to people staying at home, the integrity and security of the fuel is important for all end users. So, what is the purpose of a fuel security program?

The purpose of a fuel security program is to deter and identify illegal tampering within the fuel supply chain. Fuel crime costs governments and businesses over $100 billion per year, increases hardship on the local population, and funds organized crime. Combatting fuel fraud is a simple way to protect brand integrity, increase tax revenues, reduce crime, and improve quality of life.

With 20 offices in 16 countries, Tracerco is recognized as the world’s leading fuel marking technology provider. Our marking and detection technology enables immediate detection of fuel adulteration, and our cloud-based analysis solutions ensure that results are reported in real time so that they can be acted upon immediately.

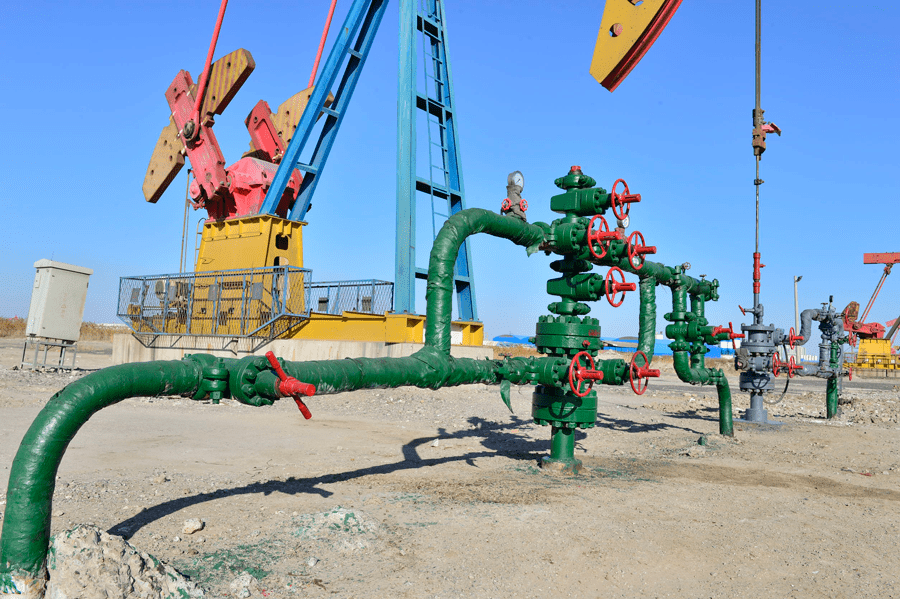

Fracking in the U.S.

Tracerco has worked with almost every major operator in the U.S. and is involved in the analyses of thousands of wells in not only the U.S. but also Canada and Mexico. Now more than ever, there is focus on maximizing returns given the current state of the industry. Tracerco added, “With the pressure on maximizing returns and reduction in CAPEX, tracers provide the low cost, low risk, and effective measurements needed in today’s industry. Tracerco has traced thousands of wells and has a 40+ year history of leading the tracer technology market for both conventional and unconventional applications.” Again, a big part Tracerco plays in fracking is with its chemical tracers.

Finally Addressing the Elephant in the Room

With the sudden drop in oil prices, decreased demand, and a glut of oil being released by the Saudis, what is your company’s plan to weather the storm?

Tracerco’s many oil and gas customers are facing significant challenges. Of course, this is not the first time the oil and gas market has dropped, but this is somewhat different from previous cycles. As a business, we are taking steps to ensure we are in the best possible position to navigate this period. We remain focused on protecting our people and financial position. We continue to invest for the future with a number of R&D projects and continue to provide technologies to global customers so they can make insight driven decisions and optimize development of their oil and gas assets.

While the times might be tough, we can see that there is a way forward as many companies are not going to let the pandemic turn into a pandemic for their companies. While there will be hard times, the oil and gas industry will pick itself up, dust off, and get back in the saddle.

Eissler, former editor-in- chief of Oil & Gas Engineering magazine, previously worked as an editor for Dubai-based The Oil & Gas Year Magazine.