Servicing oilfield assets is a difficult process to master. Exploration and production companies experience peaks and troughs in demand as oil prices rise and fall. Marne Martin, President, IFS Service Management Business Unit, says that to be successful, oilfield contractors servicing their assets must be able to intelligently scale while competing for an ever-changing volume of work by improving the customer experience, quoting aggressively without losing money, and meeting strict service level agreements.

According to Deloitte Vice Chairman and oil and gas leader, John England, the challenge facing international oil companies and large independents in the intermediate future will be effective management of capital projects. These projects can consume as much as 35 percent of these companies’ cash flows. Oilfield services are a major input for these projects, which means that service organizations capable of meeting this demand consistently are sitting in a strong position to profit.

But the Achilles’ heel hindering service companies from moving with the times, is that the software systems used throughout most of the industry are barely adequate to meet current needs, let alone adapt to new processes, workflows, and contracts. Here are four areas where oilfield service companies must be prepared for new, more progressive ways to do business with their customers.

1. Boost Contract Visibility: Be Bill Ready

Across the industry, “bill ready” is the desired state oilfield service organizations must strive for. In a bill-ready state, work can be invoiced the moment it is completed, or shortly after management review, with little or no human intervention. However, many service organizations in the oil and gas industry are still using manual or paper-based systems to manage service contracts and work performed against them. In some cases, there may be no formalized contract of work signed with a customer. That means the generation of contracts, quotes, and work orders for specific projects and invoices can become ad hoc, created manually or in separate, siloed stand-alone software.

In this disjointed environment, it can be a challenge to ensure that completed work is invoiced. The individuals sent to complete a work order are the only ones who possess the knowledge and data on what work was completed, and how much expenses were as they relate to time, parts, travel, equipment rentals, etc. Yet the crew chief charged with completing a work order on-site cannot be expected to complete the final billing process. Likewise, it can be an accounting challenge to track down the lead on each crew and ensure paperwork is turned in so work can be invoiced. Oftentimes, this results in a two- to three-month turn on invoices, which does not help the cash flow of a growing oilfield services company and only serves to frustrate the customers they are contracted to.

Fortunately, using an enterprise software solution optimized for a mobile services environment, it is relatively easy to generate an invoice automatically once the crew chief, on a smart device, signals that a billable service has been performed or a billable part or consumable used. The system should also include other processes, including customer sign-off on work, customer-specific pricing, comparison with existing contracts and warranties to ensure work is billable, and confirmation that contract deliverables are met. This results in better cash flow, lower days outstanding, and fewer invoice disputes—bringing a contractor closer to their customer.

2. Work Smarter: Retain Knowledge and Empower Your Workforce

When competition for workers is fierce, particularly when demand is peaking, the ability to keep people is a challenge for oil and gas organizations. In a manual, paper-based world, many contractors lose knowledge and even data on billable work when their key people leave. This means oilfield service providers need to find a way to capture data on the entire lifecycle of the contract, service, customer and individual asset. Otherwise, the data you need to service your customers could walk out the front door whenever a competitor offers more money.

To mitigate this, an enterprise service solution must create a transactional record of what work has been performed for each customer and how that work relates to the underlying contract. This data must be available to workers that may not have been directly involved in performing the initial work so they can understand what has been done, what is billable, and what is required by each customer and project. If a site or asset is being visited multiple times, a crew chief should be able to retrieve the previous two or three work orders for a customer before engaging in work with them. The chief can then disseminate details to the crew more quickly.

Modern enterprise software with embedded social collaboration tools allows employees to add “sticky notes” to any record in the system. These tools are designed to capture unstructured interaction and domain expertise that is difficult to document. For example, a threaded discussion about diagnostics for a heat exchange unit can be attached to the equipment object, preserving the insights of a talented technician who may have already left the company.

With the right enterprise application, the question will become not so much how to avoid loss of customer- and project-related data, but rather how best to view it in a way that helps newer employees come to understand the customer, their equipment, the contract deliverables, and the related job requirements, ultimately providing a more seamless experience for your customer and your crew.

3. Manage Assets on The Move

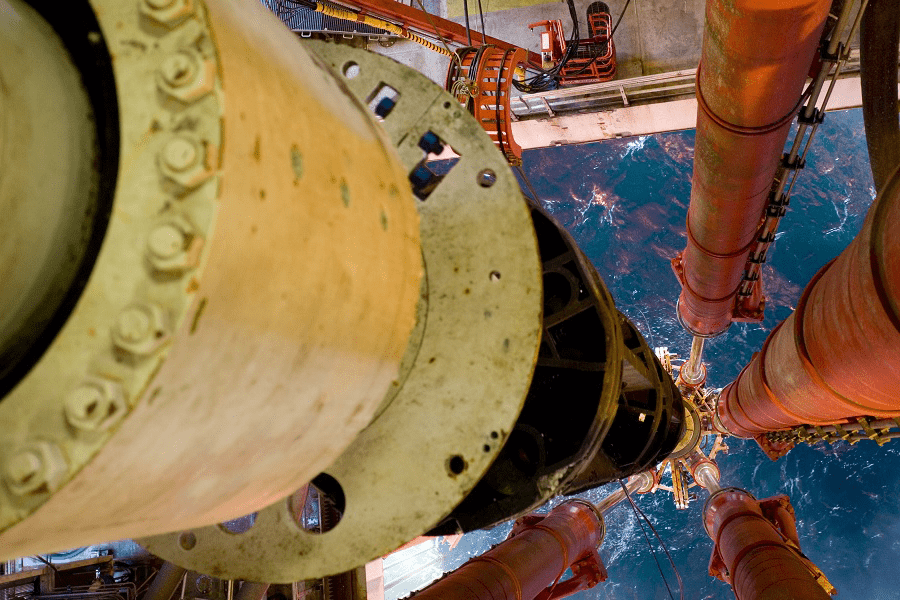

The number of assets that are rented to customers or deployed on-site by oilfield service providers can be huge. When dealing with thousands of assets, it’s easy for trucks, backhoes, workover trucks, seismic equipment, instrument air systems, and more, to be misplaced or lost permanently. Lost equipment can easily account for millions of dollars.

If a vehicle, asset or piece of equipment is making multiple stops on a daily or multi-day route, its location can be tracked by “breadcrumbing,” essentially tracking the completion of each service event and reported through mobile work order software. Tracking the movement and location of equipment in this fashion requires a high degree of integration between the equipment object, projects, and service management.

This is where GPS is a valuable complement to existing mobile order functionality, and enterprise software should be able to open the equipment record through a simple web service and pull in GPS data in the context of an overall project.

Moreover, it may also be necessary or desirable to integrate reliability-centered maintenance so you can determine whether a given service call must be completed before a piece of equipment comes back to the yard or depot. If it is not mission critical, that service could be completed a few days later with no need to dispatch a crew or technician. Or if the asset is currently in the yard, but is due for service after only a few more weeks or duty cycles, it may make sense to do a specific maintenance activity early, if it is about to be deployed on a customer site for a period of months.

4. Tech Adoption: Let It Take You Forward, Not Hold You Back

The journey to oilfield service excellence never stands still. There are a number of disruptive technologies coming to the oil and gas sector in the next 12 months which oilfield service providers can capitalize on—think equipment sensors to automate service via the internet of things (IoT) and artificial intelligence (AI) to manage customer interactions, dynamic inventories, and schedule technicians.

These are the key enablers that, once embedded deeply into the business processes, can help you leapfrog competitors, and have an easier time winning and retaining business. When oil prices drop, these technologies can also help oilfield service companies complete more work with fewer people, and on the flip side, allow them to scale up quickly during peak times as oil prices rise.

However, it’s the underpinning enterprise software which helps oilfield service providers adapt to new business processes and technologies alike, enabling them to profitably price, sell and deliver on aftermarket service. As customers contract more for outcomes than discrete equipment (i.e., hours of operation, resources extracted, etc.), oilfield service providers require software agile enough to price and support these contracts.

Be Flexible to Accumulate

High asset volumes, strict service-based agreements, and fluctuating commodities make revenue generation in this industry fragile and subject to change. Oilfield service organizations with the inherent flexibility to respond to their customers’ peaks and troughs, while keeping control of their own contractual goals, equipment, and workforce will see the largest gains in their sector.

As both President of IFS Service Management and CEO of WorkWave, Marne’s focus is to continue to elevate the strategic importance of service management to the success of the overall IFS business. Marne works strategically to ensure the entire portfolio of IFS’s service management solutions provide customers with the business value they expect from a global industry leader in field service management (FSM).

Prior to IFS, Marne served as CEO and led the executive leadership team at ServicePower Plc., a field service management software company, where she transformed its go-to-market strategy and shifted its focus to SaaS and managed services revenue, increasing pipeline every year during her tenure. Prior to that, she served as CFO of Norcon, Plc., a UK-based telecom and defence consulting firm, where she grew the company from a business largely dominant in only the Middle East to one diversified across the US, Europe, the Middle East and Asia Pacific.

Martin is a winner of a number of awards including 2016 CEO Gamechanger of the Year (FSM) from ACQ 5 Global Awards and 2015 Field Service CEO of the Year from Executive Awards. When not working, Marne enjoys competing in dressage and supporting girls and women pursuing STEM careers.