Tonae’ Hamilton: What sparked your interest in mechanical engineering and developing engineering solutions for oil fields?

Tonae’ Hamilton: What sparked your interest in mechanical engineering and developing engineering solutions for oil fields?

Founder, Midnight Tools

Michael Jensen: I have always had an interest in designing machines and spent a lot of my free time before college building things like a 22-foot-tall trebuchet with a half-ton counterweight and a competitive racing electric car so mechanical engineering was a natural choice. I was drawn to the oilfield by the challenges of designing for the extreme conditions found downhole, offshore, and subsea as well as the cultural focus and commitment to research and development found in many oilfield companies

TH: Having worked for Schlumberger, a giant oil service company, for several years, what made you decide to leave and start your own company?

MJ: I enjoyed working for Schlumberger but in the large company environment people tend to end up siloed into narrow functional roles and are generally forced to choose between technical and leadership roles. I am a firm believer that, especially in product and development organizations, the most effective leadership teams remain highly technical and involved in the creation of the products they oversee. Starting my own company provided a way for me to maintain a focus on both engineering and leadership as I moved forward with my career.

TH: Can you provide details on how Midnight Tools started and how the name of the company came about?

MJ: I had considered starting my own company since college, but wanted to, at least in the initial phases, remain internally funded. During my previous career I built my own personal prototype machine shop and set aside capital so when Midnight Tools was launched several key infrastructure elements were already in place. Our initial development choices were focused on products where we believed that new intellectual property could be developed and protected and still had low enough initial capital requirements to make bootstrapping possible.

During our early product brainstorming sessions one of the things we examined was what sets oilfield operations and tools apart from most other industries. A feature which stood out is the high value of time, especially offshore, and the true 24-hour operating environment which comes from this. The name Midnight Tools was selected to reflect that our products are designed for this environment where tools always need to work and use at midnight is as common as any other hour.

TH: Can you highlight the differences in working for a large oil service company like Schlumberger compared to owning a small local company like Midnight Tools? What adjustments have you had to make, if any?

MJ: Working for a large multi-national company, the level of resources and particularly capital you have access to is dramatically higher, the difficulty is that with these resources comes very significant organizational inertia. The current trends away from vertical integration and towards global sourcing of everything from project teams to prototype parts add to this problem. I used to spend a significant fraction of my workdays coordinating with outside companies and remote resources as well as working on the procedures, reports, and approvals necessary to move a project forward.

In the small company environment, we can be much more agile. At Midnight Tools, decision making is streamlined and we have the facilities and knowledge to design, fabricate, and test internally so we can take an idea from concept to testing in days instead of months or quarters. This allows us to take more design risks and go through more product iterations. The challenge is that, especially with seeking to remain internally funded, our resources are much more limited. This means that while our structure allows us to ‘fail fast’ and quickly develop concepts we need to be careful that once we move forward with a product, we don’t have major setbacks since there are few second chances once we reach that level of investment.

TH: What is the mission of Midnight Tools and what are you hoping to accomplish/continue accomplishing with the company?

MJ: We appreciate well thought out and elegant engineering solutions and try to develop products which are novel, useful, and have the hallmark of elegant engineering: they appear obvious in retrospect.

TH: Are there any products or software currently being developed by Midnight Tools that you can share? Can you also share information on your patents and the impact they have made on the oil and gas industry?

MJ: We currently offer several commercial products and continue to develop new configurations of these tools as well as work on new ideas, but don’t have anything new on the hardware front that we are ready to share today. Thus far, our products have been hardware based, but as part of our design process we have developed numerous internal software tools that we are considering refining into a software product to support and streamline product development. On the intellectual property front the 24+ month examination backlog at the U.S. Patent and Trademark office means that none of our patent IP has made it past the first office action stage yet but we hope to see this changing later this year or early next year.

TH: In addition, which products or patents are you most excited for your clients to utilize?

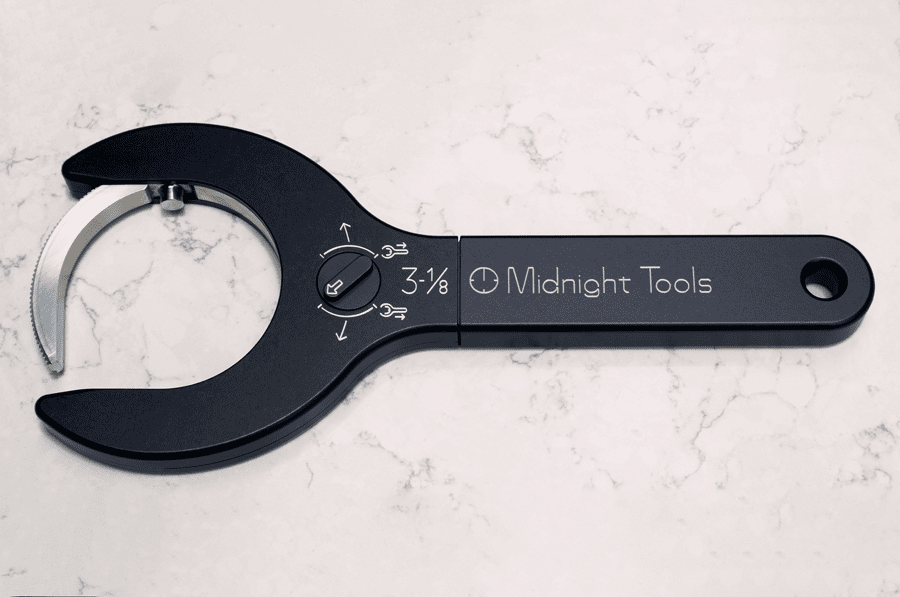

MJ: Currently I am most excited about our Continuous Spanner. This a product I wish I had during my time designing and operating wireline tools. Today most wireline tools are rigged up with a pin spanner which has remained effectively unchanged in a century. The rig up process, especially when a safety cable is used, requires frequently repositioning the spanner similar to using an open-ended wrench on a nut in a restricted space. This process is neither efficient nor ergonomically friendly and is especially costly in rig environments where day rates can range from $7 to well over $100 per minute. The Continuous Spanner is the only tool of this type that provides 360 degree bi-directional ratcheting which removes the need to reposition the tool and significantly increases the speed of the operation. Considering the number of tool joints and the frequency of rig-up and rig-down events the time savings can add up quickly.

TH: In what ways has Midnight Tools supported the oil and gas industry thus far? How do you hope to support or impact the industry in the future?

MJ: We currently support the oil and gas industry by developing specialty and niche tools to address the unique challenges and operating conditions present in the industry. We have also worked directly with clients to create customized solutions for their particular operational needs. Going forward, we plan to expand our commercial product offerings as well as continuing to provide custom tool design and fabrication services.

Tonae’ Hamilton has been a contributor and associate editor to the magazine for two years. She has been writing professionally for almost four years. In her free time, Tonae’ likes to spend time with her three pets, cook, and binge-watch Netflix shows. Tonae' has a Bachelor of Arts in Communication from McDaniel College.