The pipeline industry continues to advance its processes to address the ever-changing risks to pipeline infrastructure, and when it comes to pipeline safety, the work is never done. By growing and maintaining a skilled workforce, increasing process safety, maturing risk management programs, increasing operational efficiencies and searching for innovative ways to obtain and use pipeline data, pipeline operators can raise the bar on pipeline safety year after year.

Hiring, Training and Retaining Talent

It takes an army of specialized workers to build and maintain America’s pipeline infrastructure, and these operators and technicians are at the heart of pipeline safety. For years, the industry has faced a shortage of skilled employees to meet the demand of pipeline growth and increasing maintenance requirements. This dynamic has been exacerbated by intense competition in regional markets and a large number of experienced employees that are retiring. As a result, operators can find themselves in painful pricing wars with neighboring competitors over talent or investing time and money into training new employees only to have these employees leave before full productivity is reached.

The go-to answer for this issue has been to develop an effective workforce strategy that lays the foundation for long-term actions to attract talent and weather business cycles. However, this is sometimes easier said than done, and it often requires years for the strategy to take shape and deliver results. Operators can add a twist to the conventional workforce strategy by focusing not only on hiring more people but also on how work can be performed differently to free up capacity for existing resources.

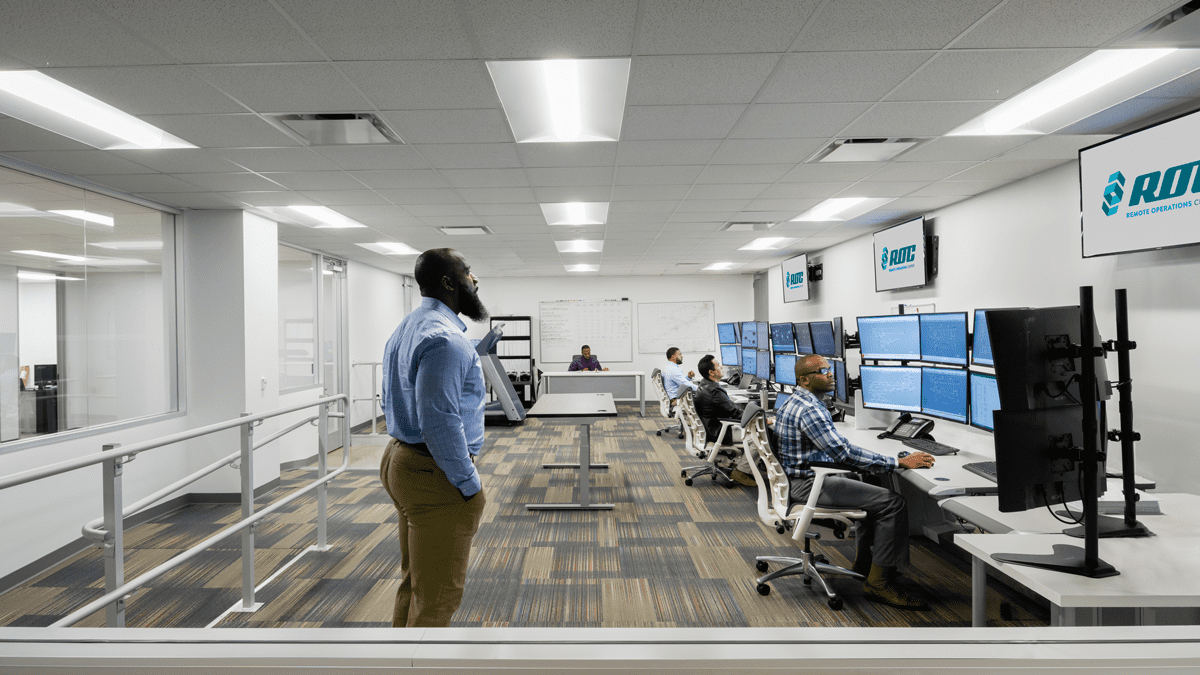

As an example, operators are starting to look for outsourced solutions for workstreams that have traditionally been performed in-house, such as the pipeline control room function. Control room employees are vital to pipeline safety and efficiency. Without controllers, rapid recognition of safety issues and the ability to meet scheduled customer commitments is not possible. Outsourcing the control room offers numerous benefits, including immediate access to skilled resources, low turnover, and significant cost savings.

Establishing and Adhering to Operational Processes

With so many unknown variables involved in pipeline operations, robust operational processes are a critical element for safe pipeline operations. The pipeline community overall is committed to a goal of zero safety incidents, which means the industry and public rely on each operator’s safety processes.

Establishing comprehensive processes across an organization can be a Herculean effort, but it is only half the battle. Once processes are developed, an operator must develop a mechanism to track adherence, take corrective actions, and adjust methods as conditions change.

Ultimately, processes create a common understanding of expectations, consistency in performing tasks and higher predictability of outcomes. Process management can be a substantial operational and administrative challenge, but the benefits to pipeline safety far outweigh the costs. Organizations can’t develop a mature process safety culture overnight, but a little goes a long way and operators can recognize immediate benefits just by starting the conversation.

Operators looking to improve processes or interested in learning more about process safety management can utilize industry standards such as OSHA 1910.119 as a starting place.

Understanding Operational Risks to Prioritize Investments into Assets

The inverse correlation between risk and safety is undeniable. Organizations that are laser-focused on understanding threats and risks, prioritizing those risks and then investing in mitigations will significantly increase operational safety.

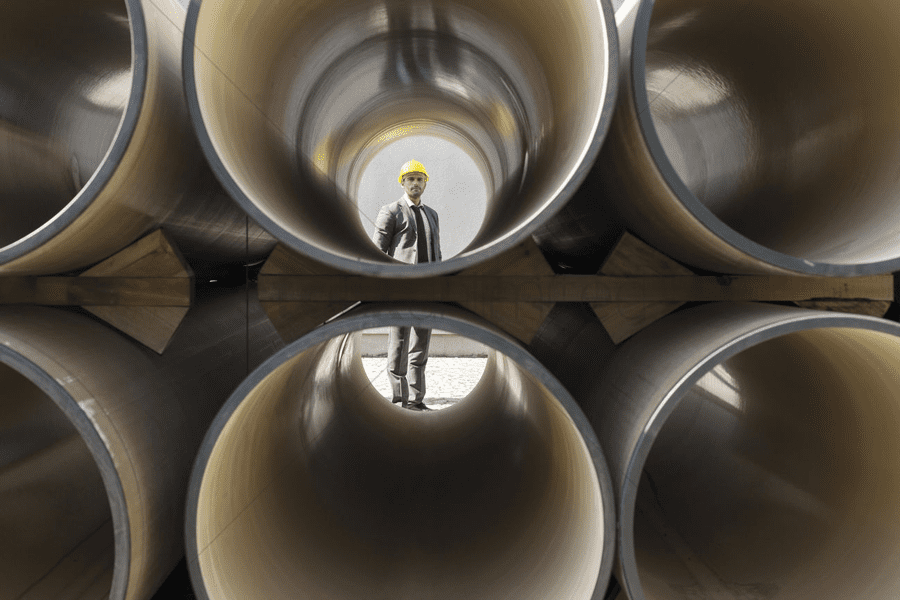

Every year, pipeline operators spend billions of dollars building new pipelines. On top of these investments in new facilities, operators are investing the same amount maintaining, repairing and replacing existing pipelines. From a financial perspective, protecting those investments is important, but protecting people that work or live near pipelines is paramount. Any time a pipe loses containment of the product it is transporting, there is a risk to human life.

Informal risk management is inherent in pipeline operations, but most operators are doing much more to formalize their risk management processes and align risk management with company strategy and field execution. The industry has taken a significant step forward in combining operational data with asset data and periodic inspection records to analyze risks by individual pipeline segment. This information can directly inform the allocation of capital across assets to address the highest risks.

Threats and risks can change every day due to new data obtained from improved technologies, external forces such as seismic activities, increased populations near pipelines, and time-dependent threats such as corrosion. As a result, risk management is a continuous process that demands constant attention.

Increasing Operational Efficiency

Often, the term “efficiencies” relates to reducing budgets and cutting costs. However, being more efficient should equate to doing more with existing resources – getting more work done – whether budgets go up, stay the same, or go down.

The need for more efficient operations has never been greater. With increased competition in the pipeline and midstream space, regulatory requirements continue to expand, pipeline safety is a top priority for all operators, and the public has aimed a spotlight on a once relatively hidden industry.

As organizations continue to seek innovative technologies and more efficient ways of getting work done, savings can then be re-invested in asset-based opportunities or invest in growth opportunities. The outcome is an industry that continues to grow while also increasing the safety of existing facilities.

The More You Know

The More You Know is NBC Universal’s long-standing cross-company public service initiative focused on education, diversity, health, civic engagement and the environment. Its title and concept ring especially true for pipeline operation. The more quality information and data that’s collected, the better-equipped pipeline operators are to understanding operating conditions and making informed decisions.

This is an exciting time for the industry when it comes to knowing more about pipeline assets and using that information to increase safety. Advances in sensor technology, networking, and data aggregation allow a constant stream of diverse operational data to reach manned control rooms that monitor, analyze and control pipeline safety 24/7. Aerial imagery coupled with sophisticated algorithms allow for the detection of safety issues on pipelines much faster than previously possible. Every year, inline and NDE inspection tools advance the ability to detect and size pipeline defects.

Ultimately, we can’t fix what we don’t know and not knowing is not acceptable. The industry should be very proud of the advances to date and continue to push to recognize more.

Photo courtesy of Remote Operations Center

Louis Krannich, is VP Compliance and Technical Operations, LineStar Integrity Services, a fully integrated suite of pipeline compliance, technology and integrity maintenance.