In the oil and gas industry, the complex design and engineering of Extended Reach Drilling (ERD) wells, which may have horizontal sections spanning more than 20,000 feet, introduce significant challenges to meeting specific drilling and geological well objectives. Drilling to ensure that all reservoir objectives are met requires the deployment of customized Logging While Drilling (LWD) technologies that will provide real-time, subsurface formation data for on-the-spot reservoir analysis.

An amalgam of adverse downhole drilling conditions is responsible for high shocks and vibrations on the bottom hole assembly (BHA) while drilling. These might include difficulty in transmitting drilling weight effectively from the surface to the drilling bit, leading to negative revolutions per minute (RPM); drilling through non-homogeneous formations; and increased contact with the formation due to the size selection of the drill pipe and stabilizer. If these conditions are not effectively eradicated during the BHA design phase, adequate mitigation measures are required once drilling commences to prevent premature downhole tool failures. This typically involves finding a combination of drilling parameters such as Weight on Bit (WOB) and RPM that offers the least damaging effect on the BHA. Some cases also may require pumping mud lubricants to reduce friction.

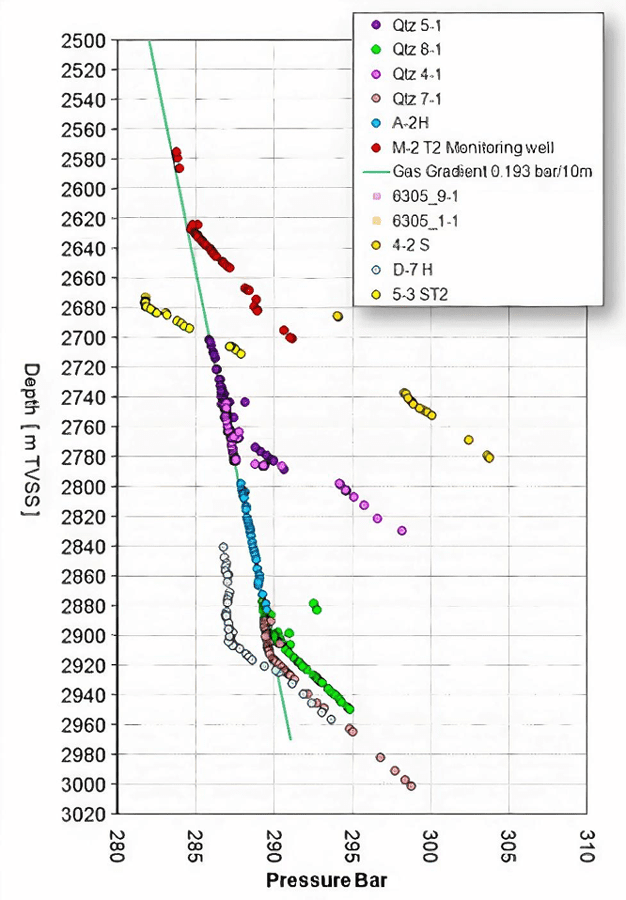

In ERD wells, the formation pressure at well total depth (TD) must be able to transport the formation fluids (oil and gas) to the surface post-completion. Real-time formation pressure measurements taken while drilling will help in calling TD, especially while drilling in reservoirs that have been producing for some time and where pressure depletion is expected. Formation pressure (pressure exerted on fluids in the reservoir pore spaces) varies with depth and exerts an energy which normally drives the formation fluid post-drilling from regions of high pressure (downhole) to low pressure regions (surface). Because this reservoir energy reduces over time, an accurate idea of the formation pressure profile is critical in determining total depth (TD) of a well being drilled. Figure 1 illustrates how, in development fields where multiple wells have been drilled and are producing, the reservoir energy drops, leading to eventual depletion: pressure points taken over time indicate a decrease in formation pressure.

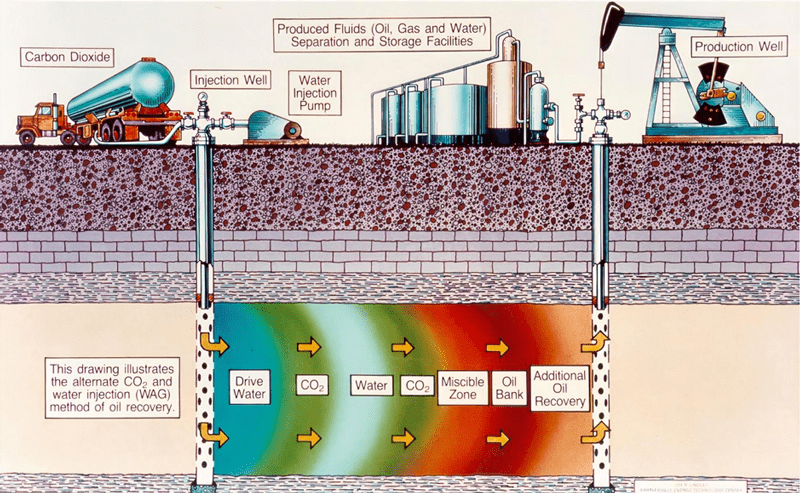

Injector wells can help generate additional oil and gas production in depleted reservoirs where there are no faults or flow barriers. After drilling the injector well, water or gas (or a combination of both) can be pumped in to increase the reservoir pressure in the connected producing well. Figure 2 shows how low reservoir pressures can be increased to drive production output.

Formation pressure measurements are taken while the drill string is stationary, requiring zero rotation or movement during drawdowns to prevent damages to the pressure probe and piston. Once the sealing rubber on the formation tester tool is damaged, getting a seal (complete isolation with fluids in the annulus) with the formation will be almost impossible, leading to pull-out-of-hole (POOH) events. In the past, having an idea of formation mobility could help in selecting the correct type and duration of pressure tests. High-mobility formations have faster pressure buildups, while low-mobility formations require more time. These delayed buildups can lead to extended stationary time which, if not monitored, can pose a risk of differential sticking, such as stuck pipe incidents in which the rig will need to implement a series of anti-stick activities to free the BHA. And in those cases where LWD tools in the BHA contain radioactive sources, all efforts to free the stuck pipe must be made to prevent loss of the sources. Further complicating matters, most of the formation pressure testers are modular in design, with interconnected modules, which in very high downhole shock environments can undergo lateral and transversal vibrations that may lead to damages in electronic and mechanical components prior to reaching the pressure points.

These two concerns often prompt oil and gas operators to have a dedicated run post-drilling for the evaluation of formation pressure. This dedicated run, called the Measurement After Drilling (MAD) pass, commences after drilling is completed and the well is in a stable state. The MAD pass occurs most often after a series of bottoms-up circulation for hole cleaning and well monitoring to confirm that the well is not flowing prior to pulling out of hole with the drilling BHA.

MAD passes offer minimal adverse downhole conditions during formation pressure testing, less chances of stuck pipe incidents (due to small BHA contact areas with the formation), and can be utilized for additional clean-out runs prior to running the completion string(s). Pressure measurements during MAD passes in ERD wells typically take an additional 48 to 72 hours of rig time – from tripping in hole, taking pressure points and pulling out of hole. Yet, because the pressure points taken during MAD passes are post-fact, they are generally not beneficial for real-time drilling decisions. Hence, selecting the appropriate pressure testing pass is critical to meeting all reservoir objectives. Some of the real-time benefits derived from LWD formation pressure measurements that are not available in MAD Passes include:

- Optimization of mud weight: formation pressure measurements can be used to identify pressured zones and can help in adjusting mud weight to match reservoir pressure, ensuring that drilling can continue safely with reduced drilling kick risks.

- Optimization of reservoir hole length: formation pressure measurements taken along the reservoir path help in confirming whether reservoir pressure at specific depths is sufficient for normal flow of oil and gas formation fluids to the surface.

- Mobility guided steering: formation pressure measurements taken along the well path will help in avoiding high viscous reservoir fluids like bitumen or tar in known reservoirs. These viscous layers cannot be detected with conventional resistivity/density logs, and can only be identified using mobility measurements derived from formation pressure. Pressure tests in tar are often dry (very low mobility), so the well can then be steered upward to move away from the tar layer.

With the numerous benefits provided by LWD pressure measurements, it is then essential to eliminate any drilling shortcomings and/or challenges to making this method the pressure testing mode of choice. BHA design must incorporate shock reduction subs and optimal Hevi-Wate drill pipes (HWDP), with sufficient quantity and placement to ensure efficient transmission of drilling weight from surface to the drilling bit. Also, ruggedization of the electronic chassis in the formation tester tool will reduce the lateral and transversal vibrations while drilling. Meeting both of these conditions will reduce the risk of premature tool failure. Another key factor is the reduction of stationary time while taking pressure points in low-mobility formations. This stationary time has now been reduced with the advancement in software technologies in which the formation tester tool can determine the amount of drawdowns and duration for various mobility ranges instead of the fixed time pressure point measurements.

Every ERD well is planned to be delivered within its approved authority for expenditure (AFE). This raises the impact on cost management, because all extra rig hours and days for additional runs – time that may have been avoidable – will be reviewed, especially when these additional services can be delivered while drilling. LWD also delivers critical information required to extend the length of the drilled reservoir. Ultimately, increased production capacity is available with LWD, as opposed to MAD pass runs, where information about formation pressure is obtained after drilling has been completed, making LWD the preferred pressure test for ERD wells.

Headline photo courtesy of Adedayo Iroko

Adedayo Iroko is an engineer and expert in drilling engineering management for the global oil and gas industry. As a Geomarket Resource Manager in Drilling & Measurements for one of the world’s largest oilfield services companies, he specializes in leading state-of-the-art ERD, MWD, and LWD operations. Mr. Iroko also brings his 15 years of oilfield experience to training drilling engineers in new technologies and processes.