Below is an interview with Keith Arnold. The interview text has been left in tack, with only minor grammatical adjustments.

Eric Eissler: Could you give me an overview of your operations in the Oilfield and Lubricants and additives? For the oilfields could you provide our readers some perspective as to where you operate and in what sector of the industry you work in, up, mid, or downstream?

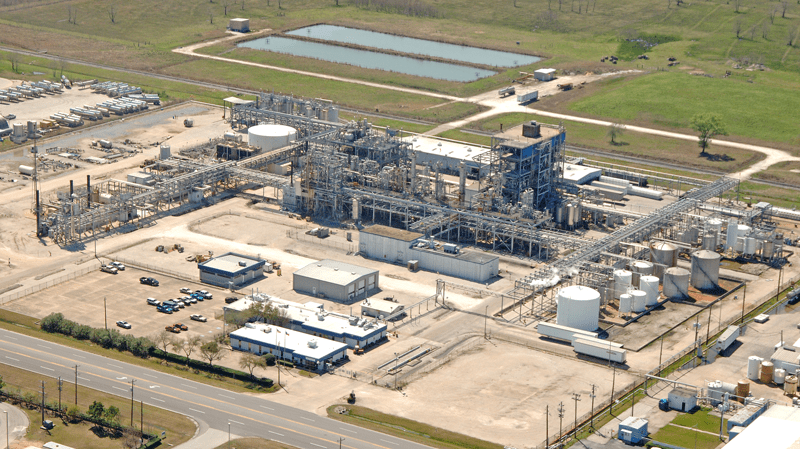

Keith Arnold: MFG operates three plants in the North Georgia area. The acquisition of our Pasadena, Texas plant was made in March 2018 due to the fact that there was much business, and it prompted the purchase of two new reactors, one of which is 20,000-gallon in size.

We work in all streams. MFG Chemical was founded in 1979 and started to evolve in the 1980s to become a custom-contract chemical manufacturer. This means that companies work with us to develop custom chemical solutions to meet their needs. We started off by buying certain chemistries, derivatizing these chemistries and selling it back to them. Later, we partnered with a large oilfield service company. We were then channeling large oilfield services companies and used a partnership formulation to conduct business. A lot of the chemicals we manufacture for the upstream sector are corrosion inhibitors, emulsifiers, fracking fluids, and stimulations. Again, we are providing custom chemical manufacturing. This custom chemical approach allows the chemical production to stay domestic in the USA, so companies are not going overseas with their intellectual property.

EE: I see you are doing some work in fracking chemicals. Could you elaborate as to what types of chemicals you are using to produce these fluids and what you are doing to ensure that the fracking fluids are not having a negative impact on the environment?

KA: For sustainable fracking fluids, most of our customers are large and have the chemists that can work together with us to produce environmentally friendly chemicals. In this fashion, we can be fast to react to our clients’ needs and then get the chemicals to market quicker. We would love to see oil get up to $55 to $70 USD per barrel because this aids development and investment for cleaner and better environmentally friendly chemicals. Furthermore, the higher price of oil is better for the economy. If it is too low, the economy lags.

EE: Energy production is the basic building block of the economy, so it is important for it to be a robust, healthy industry.

KA: You are absolutely right.

EE: Could you tell us some more about the recent Pasadena, TX plant? What type of operations are going on there?

KA: This was a long time coming as we looked for a site for four years, either a greenfield or a joint-venture or an acquisition. We were looking for a joint-venture but the potential partners did not have capital to expand and MFG Chemical wanted to get into the gulf coast because of our customers in that area, bulk rail car shipping and the proximity to the oil and gas market.

EE: Could you tell our readers where you would like MFG Chemical to be in the next five years?

KA: We are bullish on the market, but volatility is everything. When oil and gas is up, the market is really up; and when it is down, it’s really down. It is a market that swings wildly from time to time. We have a customer base and we have a lot of them committing to contracts. We would like to have three more expansions over the next six years and stay focused on oilfield production and rheology modifiers. We are aiming to be more diversified throughout the oil and gas value chain. Therefore, diversification is the key to being successful.

EE: On a closing note, congrats on winning the Plant Safety Performance Improvement Honor! Could you go into the details about how you achieved this?

KA: We have been on the environment, health and safety journey since 1979 and have been trying to change the culture to make safety a core value in every single thing that we do. Each year we look at operations and training and submit to SOCMA® for our performance improvement. We do it because it lends itself to credibility for us and to our customers, who are most important. What is most important to customers is the commitment and safety standards of the company.

MFG Chemical, LLC is a leading specialty and custom chemical manufacturer for a variety of global markets, including agriculture, asphalt, graphic arts, lubricants, mining, oilfield, paints & coatings, personal care, pulp & paper and water treatment. The company is headquartered in Dalton, GA, and operates four manufacturing facilities with world-class product development capabilities in Northwest Georgia and Pasadena, Texas.

Eissler, former editor-in- chief of Oil & Gas Engineering magazine, previously worked as an editor for Dubai-based The Oil & Gas Year Magazine.