Fleet Performance Optimization

People often refer to owning a boat as the equivalent of having a hole in the water you throw money into, referring to the consensus that boats are money pits. Well what if those boats were massive in size and there were many of them? What if millions of dollars were potentially at stake because the cargo was a vital resource that must be adequately monitored and maintained? That becomes quite a bit of a game changer. There are ships all around the world that hold and transport one of our most valuable resources, fuel. Because of this, it is critical that the fuel is measured and analyzed with pinpoint accuracy, to increase the bottom line, ensure efficiency, and improve the overall performance of a fleet.

There are several ways to monitor and optimize your fleet and the cargo it holds, although, only one company holds the patent for the apparatus and method of fuel measurement and accountability – FUELTRAX, the universal fuel management system that operates on any vessel and in any location in the world. FUELTRAX is not only the industry leader in EFMS (Electronic Fuel Monitoring Systems) using its patented technology but also the first to market and the vanguard in modern Marine Fuel Management. They are changing the game in fuel monitoring and reporting.

The Beginning of FUELTRAX

FUELTRAX was initially designed and engineered in the field as a project for Kirby Corporation, the largest inland waterway operator in North America. Kirby wanted a custom-fit system to measure fuel consumption on their inland push boats and approached Anthony George at CDI (Control Dynamics International), an engineering company that specialized in offshore automation and control systems.

George realized that he had a unique product that could make a difference for the commercial marine market. Nautical Control Solutions, LP (NCS) was created in 2006 as a spin-off of CDI, to develop and take this product to market. The United States patent protection was granted in 2006 with Canadian and European Union protection following in 2012.

Today, FUELTRAX has grown into a market-leading electronic fuel management system, operating on hundreds of vessels across the world. It offers secure, smart monitoring with direct fuel measurements and advanced data analytics, helping customers reduce costs, ensure compliance, and enhance performance.

FUELTRAX empowers customers with increased transparency in reporting, which allows for improved inventory control and loss prevention, especially in areas subject to pilferage, piracy, or other common causes of inventory loss. Before FUELTRAX, this level of insight to operations wasn’t available to vessel owners. By eliminating the need for human input, FUELTRAX makes fuel reporting a trusted, automated, secure, and reliable solution – all to drive improved efficiencies in fuel consumption and fuel quality assurance.

In addition to fuel monitoring and reporting, FUELTRAX also offers crude monitoring and transporting for companies that specifically request that service.

Revolutionizing the Industry with Technology

Technology is the driving force in the success of any business in almost any industry in today’s world to which oil and gas is no exception. Machine learning, artificial intelligence, and the IoT have entirely revolutionized every aspect of this industry, making companies more efficient and improving their bottom line, which was not lost on FUELTRAX.

With the release of FUELNET Generation 5 (GEN-5), users can now access crucial weather data metrics, which are activity time-stamped and linked to vessel geolocation and stored historically with all-weather parameters.

FUELNET takes the risk of human error out of the equation. It captures and reports the needed data to prove full compliance with MRV (Monitoring, Reporting and Verification) and DCS (Data Collection System) – with no need for human intervention. FUELTRAX automatically generates reports from direct, accurate, and reliable data tracked on board. All the facts of the fuel data are historically stored, so that it can be researched, analyzed, and applied for the most efficient outcomes.

FUELNET is a self-contained and secure cloud database, providing automated reporting of accurate vessel and fuel information. It enables you to track your assets 24/7, supporting your future efficiency and investment decisions. It is also a fleet-wide data historian, monitoring past performance and is the most powerful fuel data processing network in the maritime industry. Operating hand-in-hand with FUELTRAX, using extensive real-time data stored in its fully secure web portal, FUELNET enables vessel owners to customize their reporting data and make fleet-wide efficiency savings.

It delivers easy-to-use, end-to-end, secure communications straight to your desktop while working hand-in-hand with FUELTRAX technology installed on board. With browser access to the web portal, FUELNET provides customized reports and email alerts, enabling you to respond to data quickly, share detailed reports across teams, and manage costs and performance. The data transmission is GPS stamped, encrypted, and fully SSL secured, bypassing the vessel’s communication system.

The three-dimensional reporting of fuel consumption provides insights by usage, asset, or a customized operational ‘mode’ profile. FUELTRAX is the first and market-leading company to provide such analysis, based on your fleet’s directly recorded operating parameters.

Since most fleets are transporting fuel worldwide, compliance with international regulations is imperative. All fuel consumption data points required for the European Union’s MRV emissions validation regulations, and the IMO’s forthcoming DCS, are already measured, monitored, and reported by FUELTRAX as standard.

Since its launch 15 years ago, FUELTRAX and FUELNET have evolved to become mission-critical operating tools for maintaining accurate fuel accountability across hundreds of vessels worldwide. Through modernizing marine fuel management, clients can now make fact-based decisions based on a trusted, automated data source.

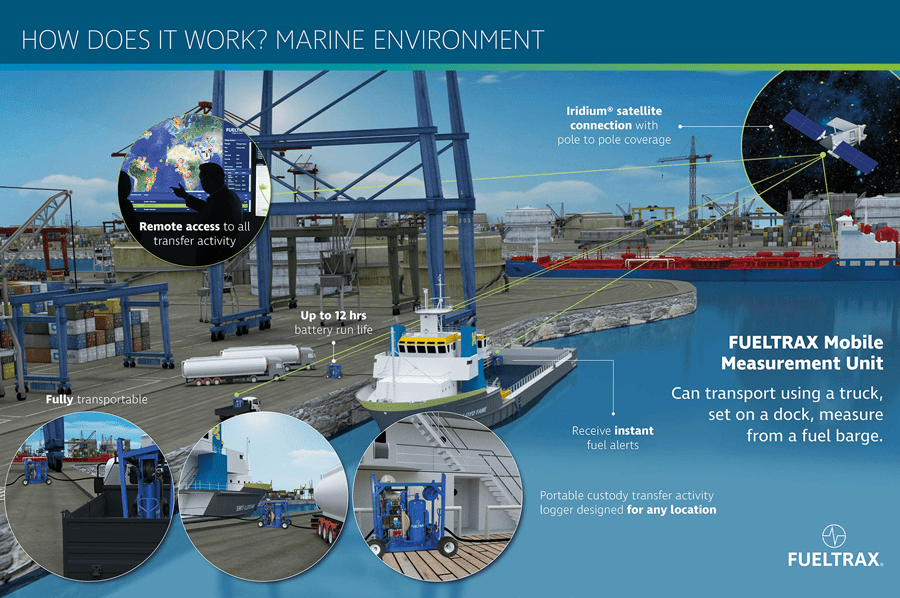

Going Mobile

FUELTRAX has also gone mobile with an integrated Coriolis mass flowmeter in a self-contained unit, designed to monitor and report custody transfers that are performed anywhere in the world. The FUELTRAX MOBILE unit, built as a standalone alone skid, is light enough to be pushed around a dock by 1-2 workers or loaded onto a truck for easy transport. All flowmeter data is securely sent to FUELNET via an encrypted Iridium signal. By replicating the benefits of the onboard FUELTRAX systems, it stands up to the challenges of providing fuel accountability and data transparency in any location. It is portable and specifically designed to be taken into the field and placed in line with existing fuel systems.

FUELTRAX MOBILE provides precise, direct measurement by custody-grade Coriolis mass flowmeter technology with +/-.05 accuracy, which brings significant efficiency to fuel reporting. The unit is GPS-tracked and automatically and digitally records all custody transfers with access to review all reports remotely. Each unit offers a touchscreen display to monitor fuel flow rate and total fuel transferred in real-time, sight glass for visual verification of flow, density alarm and immediately printed receipts, with a signature line direct from unit. It is capable of continuous operations on battery power for up to 12 hours, and recharging is simple, as it is compatible with standard global power sources.

Fuel and Fleet Security

FUELTRAX also launched an IP-video surveillance system, FUELTRAX VISION, which gives customers a 360-degree view of vessel operations, adding yet another layer of security to the smart monitoring and reporting technology already delivered.

With strategically placed cameras constantly working, they provide insights into vessel activity from anywhere in the world. All video surveillance collected is coupled with the existing fuel monitoring data and tracking information, providing greater transparency of vessel operations.

Up to 8 marine environment cameras provide 360-degree coverage of the vessel perimeter, retaining up to 10 weeks of high-quality date/time/location-stamped footage, with minute-by-minute snapshots sent to FUELNET. Video is in full 720p color and accessible by authorized personnel on board. The remote view of camera feed helps management verify the weather, HSE, or other exception claims with a visual reference. In addition, it provides power-interruption alerts and built-in backup power supply, with all components housed securely and monitored remotely.

In the News

Most recently, FUELTRAX has partnered with Dataran Elektra, Malaysian trade, and services provider. Dataran Elektra has been appointed as the first PETRONAS-licensed agent for FUELTRAX in Malaysia. As fuel consumption, transparent reporting and compliance remain under the spotlight for those operating in Malaysia, more fleets are turning to FUELTRAX for smart, self-contained fuel monitoring solutions.

This developing partnership continues to grow from high standards of success for both companies. “Early on in our pivot to the Malaysian market, we recognized the need to partner with a team that was supremely competent and shared our ‘failure is not an option’ approach to client support,” says Global Operations Director, John Donovan, FUELTRAX. “Dataran Elektra is all of that and more, with a stellar record in oil & gas and exceedingly professional customer service. We look forward to jointly exploring the many opportunities that Malaysia offers for the FUELTRAX product line.”

As the requirement for EFMS continues to expand with increasing charter mandates in Asia, West Africa, and South America, FUELTRAX remains the globally accepted standard. “The transparency of the fuel data allows charterers and OSV owners to make real, cost-saving changes to their operations based on accurate and timely data. It enhances their control over decisions that affect their compliance and performance goals,” says CEO and Founder, Anthony George, FUELTRAX.

Looking to the Future

Today FUELTRAX currently serves over 150 vessels working for oil company charters and has been deployed on approximately 500 workboats and commercial vessels worldwide since its inception in 2004.

They have the most extensive digital fleet in the world, with 15 years of operations covering 384,000 km of the globe and are consistently looking for cutting-edge ways to use this data, through advanced benchmarking, predictive analysis, and expert-built quality data sets. George says, “We look forward to building partnerships with industry-leading clients and using our data to drive insights across their global fleets which enables our clients to make the most informed decisions and provides a clear return on investment through increasing fuel controls and transparency.”

A company’s fleet is their most prized possession. It’s not like a regular business where owners can walk around and monitor employees and equipment. The equipment could be in any of the seven seas at any given time. A company has to make sure that they are covered, all the way around – figuratively and literally. The transportation of fuel is vital to this industry, and the fuel contained inside these vessels is precious. The fuel and vessel itself must be protected and monitored, what’s inside must be measured with accuracy and validated. All of which FUELTRAX offers – ultimately providing ease for their customers. When you are tasked with transporting one of the world’s most valuable resources, ease sounds like a pretty incredible proposition.

Sarah Skinner is a graduate of Louisiana State University with a degree in English. She has been a technical writer and editor in the oil and gas industry for over ten years in Houston and in Louisiana. She currently works as a technical writer for a pre-cast concrete construction company in Louisiana that builds blast-proof buildings for petrochemical plants.