No matter how frequently we travel, an inevitable reckoning of judgment captures our mood as we view our temporary living accommodations and sample the meals we must enjoy or endure. We instantly compare it to the homes in which we reside and the food we prepare in those central hubs. We often take comfort in knowing those travels will be short and temporary.

For deepwater offshore workers, 50% of their time is spent away from home and feasting on someone else’s cooking. In addition to being away from their homes, many situations reveal that deepwater offshore workers leave behind loved ones when leaving for work. If it sounds like a difficult life built upon sacrifice, it is because it is exactly that. So, how do you keep this workforce comfortable and coming back each hitch to perform the duties for which they are paid?

Along with good pay in an exciting industry, companies keep this elite workforce returning by making their stays as comfortable as possible and mirroring the same standard found at home, at the very least. The critical components to successfully muster this solution are accommodation and food, two of the key needs to survive.

Quality Living

Not only are deepwater offshore workers away from home for extended periods of time, they typically work a 12-hour shift for at least 14 days. The last thing they want to have to endure is an uncomfortable bed centered in poor accommodation. As a result, the quarters in which these workers office and live demand construction standards that maintain safety while providing comfort.

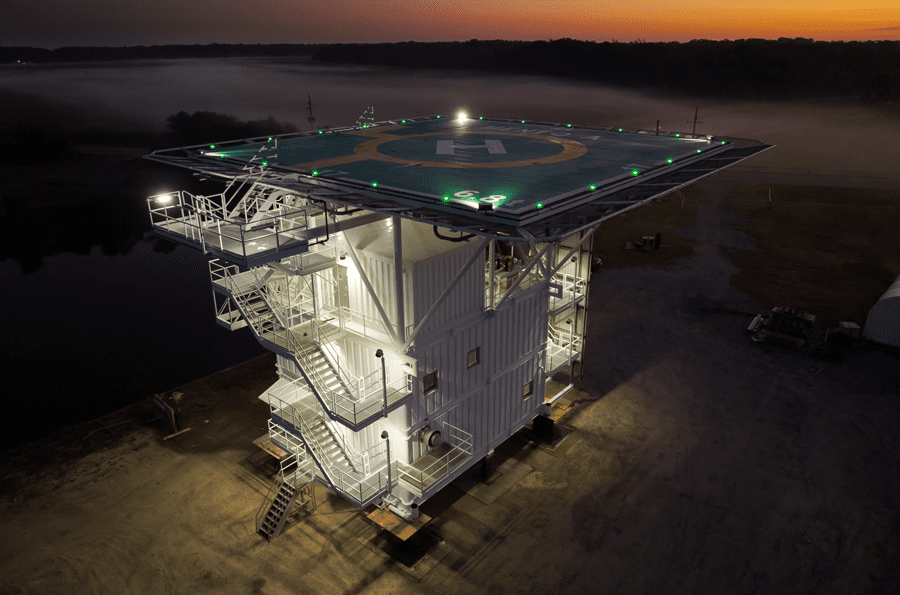

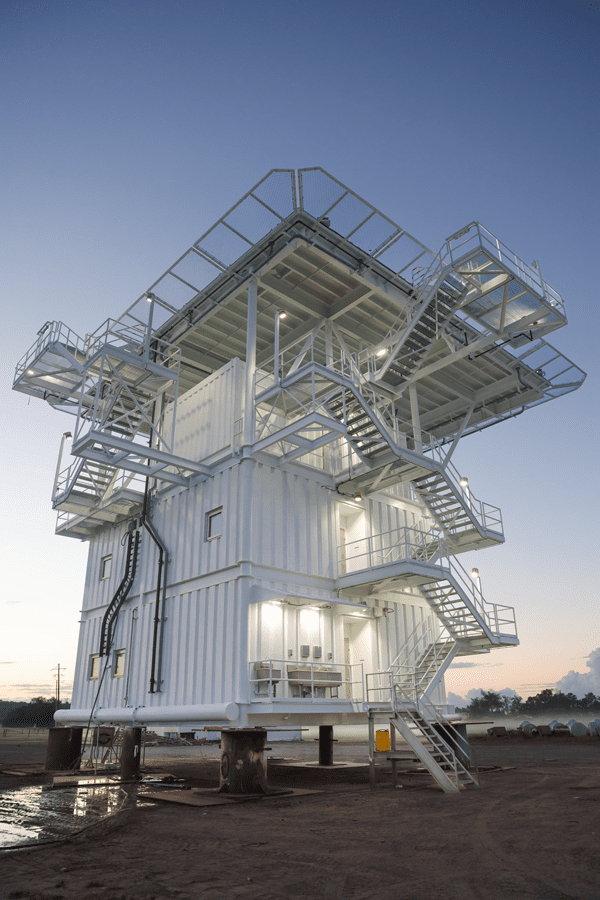

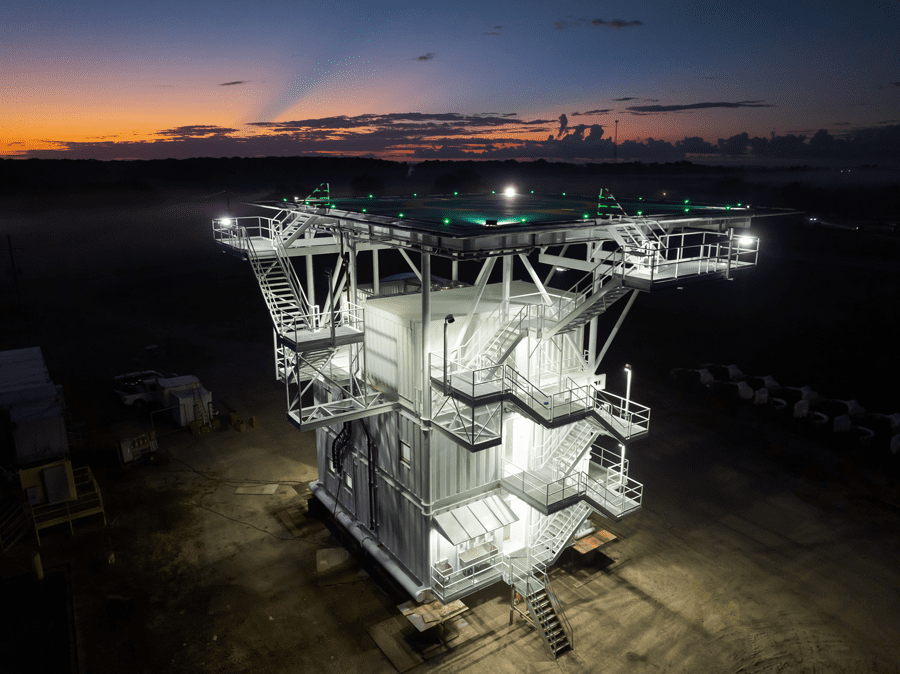

Josh Vice is a partner with Gulf Land Structures, a company that designs and builds offshore quarters for living, office space, and any other use needed. The company’s units are utilized by various industries with oil and gas being a large part of its business.

“We love the energy sector,” says Vice. “It does great things for people and the world.”

While deepwater offshore assets are outfitted with living quarters, space is limited. For large projects like turnarounds, the permanent accommodations on the asset cannot support the staffing coming aboard. Gulf Land Structures provides pre-built units to provide living space for the increased personnel. Additionally, the company designs these units and builds them according to the specifications provided by the customer.

The waters of the Gulf of Mexico can be treacherous due to changes in weather patterns, making it necessary, as Vice points out, to provide not just comfortable living spaces, but to achieve an elevated level of safety during construction.

“These deepwater assets are considered vessels, so everything built on them must meet ABS standards,” says Vice.

Construction standards can be achieved through various applications. The size of the structure, however, plays a significant role in where construction takes place. Units permanently affixed to a deepwater asset are constructed in a construction yard and attached to the asset there. These sites must include a slip for post-construction purposes. Once married to the asset, it travels to its final destination.

Design and regulations determine the materials used in construction. Ultimately, living quarters boast comfortable rooms with bedding, personal areas, and full bathrooms. These units are built to be functional and comfortable so the end of a work shift can be met with comfort to recover from a grueling day at work.

Office space and miscellaneous used structures offer the exact solutions as living quarters. Vice says they are meant to be comfortable and functional, just like anything found shoreside, while meeting the complex rules and regulations that construction designs and practices must comply with.

“Whether we are building these structures in our yard or in our customers’ locations, we have to follow design guidelines and ensure a safe product when complete,” says Vice. “It is just like building a house.”

Serve It Up

What else could an offshore worker ask for besides a safe and comfortable space to reside in? A hot meal goes a long way. Working on a deepwater offshore asset is remote. In the majority of cases, the worker doesn’t leave until that hitch is complete. Needless to say, there are no floating fast-food chains nearby, and restaurant delivery services and grocery runs are nonexistent.

Specialized companies offer the services and supplies needed to provide snacks, full-course meals, and beverages to the people who populate these assets and work diligently to complete tasks throughout their shifts. Premier Offshore Catering LLC meets these needs as a provider of groceries and food supplies, as well as the staffing needed to prepare and serve the workforce.

According to Noel France, VP of Operations, while his company’s staff does not perform the difficult and sometimes dangerous work on and within the offshore asset itself, the cooks, galley hands, and other personnel provided by Premier Offshore Catering must work within tight and exhausting schedules.

“Our cooks and galley hands are up between 3 a.m. and 4 a.m. getting ready for breakfast and then serving anywhere from 5 a.m. to 7 a.m. Afterward, cleaning and prep take place for the lunch service with snacks always available,” says France. “It is basically a 24-hour dining operation demanding a 12 to 16 hour workday.”

Depending on the direction provided by the offshore asset owner, a day and night crew might be necessary. It requires personnel willing to work long hours for an extended period of time. France indicates that many of his employees previously worked in the cruise industry.

“They seem to like offshore more than staying on a cruise ship for seasonal work,” France observes.

In addition to keeping living quarters clean and equipped with linens and supplies, cooking and serving meals reigns as a critical service. Depending on the contract agreement, France says, in many cases, his staff working on the offshore asset takes inventory of grocery and cooking supplies. Indicating what needs to be replenished, the inventory is approved for ordering and is processed through Premier Offshore Catering. While helicopters transport the workforce, supply boats deliver groceries and supplies. The inventory is properly packaged and delivered to the dock, awaiting a vessel for transport.

“All supplies are loaded into grocery boxes and prepared for safe and secure travel for the trip,” says France.

After ordering and taking inventory of the supplies and groceries, satisfying meals of variety are prepared and served to continue the mission of making offshore workers comfortable while braving the alienating reality of being away from home.

France says his company attempts to provide the familiarity and comforts of home through meal selection and good cooking. Workers waking up to the stars are greeted by large breakfasts consisting of eggs, bacon, sausage, and other selections. Sodas, hot coffee, and a variety of juices are always available.

Lunch meets similar standards with hot meals, desserts, and even sandwiches. The big show comes for the evening meal, with variety being key. The oil and gas industry thrives on tradition, and today’s offshore workers have heard the stories of previous generations telling grand stories, such as “steak night” and once-a-week fried chicken.

“We do some theme nights to ensure we offer variety,” says France. “We have Mexican night and Asian night as well.”

While the Gulf of Mexico is the target service area, France says his company services the industry from Venice, Louisiana, to Galveston, Texas. While this makes coordination challenging, France takes pride in servicing the industry. He feels that providing quality cooking and services to the people working deepwater offshore jobs shows care and support in enduring yet embracing offshore life.

“We provide groceries and personnel to offshore installations to feed the men and women who live and work offshore,” says France. “We hope what we offer makes work life easier while they are away from home.”

Nick Vaccaro is a freelance writer and photographer. In addition to providing technical writing services, he is an HSE consultant in the oil and gas industry with twelve years of experience. Vaccaro also contributes to SHALE Oil and Gas Business Magazine, American Oil and Gas Investor, Oil and Gas Investor, Energies Magazine and Louisiana Sportsman Magazine. He has a BA in photojournalism from Loyola University and resides in the New Orleans area. Vaccaro can be reached at 985-966-0957 or nav@vaccarogroupllc.com.