With commodity prices in flux, the industry seeks to adopt new strategies to increase efficiency and optimize existing assets. Producers are looking for new technologies to enhance their organizational agility and, ultimately, improve recovery rates in the high-decline rate wells.

As the industry is putting the latest technology to work, measurement departments have found themselves directly in the center of the digital transformations that are sweeping the industry. They are supporting more agile and digitized organizations. That means the ability to provide instant access to up-to-date measurement information throughout the organization is required to stay competitive, all while maintaining one source of truth.

Sophisticated measurement automation applications have been a critical enabler of the digitalization and business process transformations that production operations have put into practice. The wide variability in well and pad production necessitates accurate and timely measurement data as well as the ability to monitor and optimize production.

How can measurement departments more effectively use the information on flow rates and well performance to balance their systems and optimize production?

Measurement Automation

As measurement processes have become more complicated, automation has become a key focus in the oil and gas industry. Understaffed measurement teams are looking for software solutions that help them work more effectively, utilizing automation to synthesize the vast domain expertise and complexities into manageable workflows.

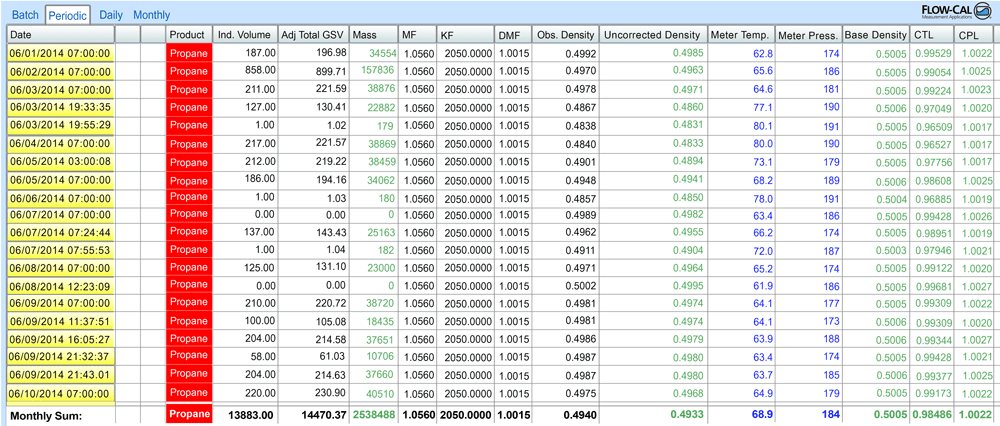

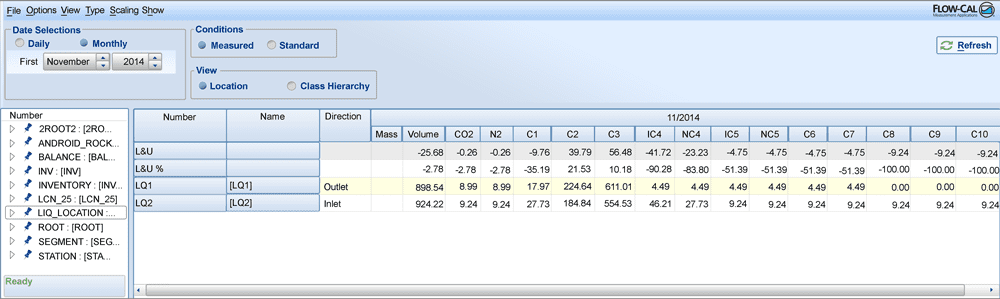

Automation allows new measurement professionals to tackle the system balance process, which has become much more complicated with the numerous mergers, acquisitions, and divestitures over the years. Both the organic and aforementioned inorganic methods of company growth have led to diversified operations, where the measurement departments must track multiple fluids such as natural gas, NGL (natural gas liquids), and heavier hydrocarbons.

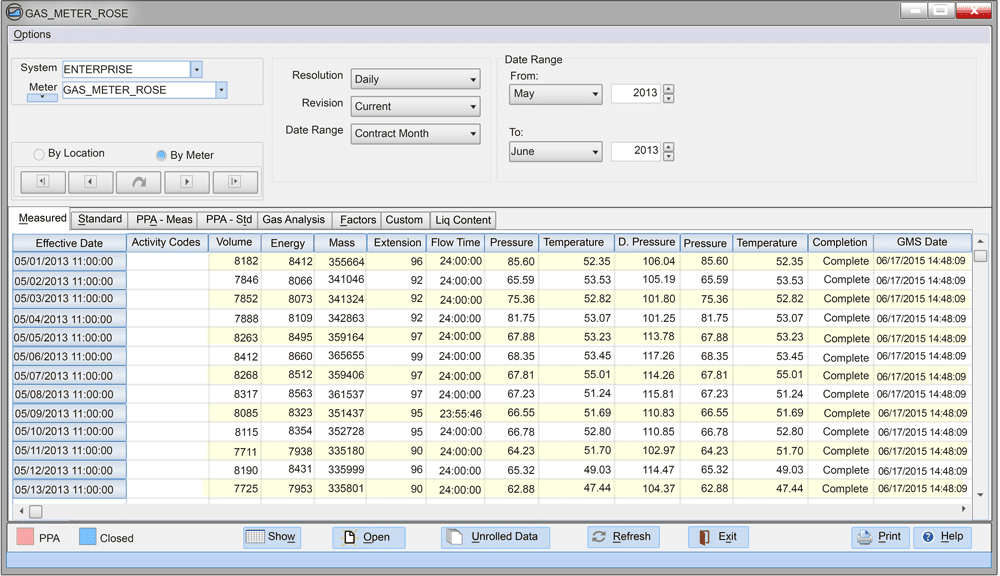

These systems will often have a variety of meters, ranging from the traditional orifice, positive displacement, and turbine types to newer technologies including cone, Coriolis, and ultrasonic. Installed on top of those meters is a broad assortment of correctors, gas flow computers, and liquids flow computers.

An operation that tracks multiple fluids must consolidate all the information from the different technologies, verify the accuracy, apply required fluid quality samples, and then recalculate as needed. Only when those steps are complete can the measurement department attempt a system-wide inventory balance.

Automated system balancing is a powerful tool that can highlight anomalies in the database rapidly as well as in the oil and gas system. Unaccounted-for losses are exposed and pinpointed through techniques such as system segmentation, and issues are brought to light, for example, equipment failures, leaks, and deviations from standard operating procedures.

Recent changes to the API Manual of MPMS (Manual of Petroleum Measurement Standards) include the introduction of three-dimensional, physical properties tables and a completely updated 2nd Edition to Chapter 21.1, Flow Measurement Using Electronic Metering Systems—Electronic Gas Measurement. A modern measurement application ensures all functionality stays current with all applicable standards.

Measurement automation applications also provide editing, reporting, and data export capabilities that ensure compliance with audits, industry regulations, and standard operating procedures. Data validations and system balancing flag data anomalies, account for missing data, expose sources of unaccounted-for inventory, and maximize the integrity of the measurement information.

Furthermore, the measurement applications integrate measurement office operations with field technician tasks and allow everyone to work from a common database and reports. The integration significantly reduces potential sources of error and increases efficiency across all departments.

Data Integrity

Data validation is critical for today’s oil and gas companies to reduce their risk profile and ensure accuracy in reporting to both stakeholders and external authorities. This is possible because measurement automation applications employ sophisticated data validation capabilities. The result is an overall improvement to measurement information integrity that not only meets industry and regulatory audit requirements but directly impacts the bottom line.

A data validation process flags potential anomalies and brings them to the attention of the measurement staff. Numerous checks and balances are applied to flowing parameters, meter characteristics, quality information, and rolled-up historical averages and totals.

For a measurement analyst, this can save significant time that would otherwise be spent sorting through large amounts of data to locate problems long after they occur. Instead, the system flags the issues and analysts can work to solve them immediately.

Information that fails a validation test creates an exception in the measurement system, which are reviewed by the measurement staff, typically daily. Through this review, the team identifies and resolves most issues on the same day.

Issues are tracked throughout the year to determine if equipment needs to be upgraded or replaced or if a new design is needed to resolve an ongoing problem. Before closing each month, all exceptions are either resolved or flagged as process-pending.

Conclusion

It is necessary to understand flow rates and individual well performance to optimize production, enhance production economics, and improve recovery rates in unconventional wells. The increase in variability and complexity in well and pad productions are driving companies towards automated systems and more accurate data for better operational monitoring and optimization.

Modern measurement automation software encompasses the vast expertise that only the most accomplished professionals held. The applications process the considerable amount of data that is provided by measurement equipment at remote well sites and presents it to management in an effective manner. Also, users benefit from improvements to compliance, enhanced production, increased asset efficiency, and lower operating costs.

Duane Harris, an experienced energy sector professional, has more than thirty years’ experience in gas measurement technology with a focus on data integrity and corporate measurement procedures. He gained much of his experience as a Measurement Manager for a major pipeline company. There, he was responsible for overseeing all measurement functions, ensuring data integrity from the field to the corporate office.

Duane has led and holds a number of respected positions within the various measurement schools and committees around the country including current board member and former general chairman and president of the American School of Gas Measurement and Technology, as well as former president of the Gulf Coast Gas Measurement Society. He has also published and presented numerous whitepapers for several industry organizations both domestic and international.