The first step in ensuring a safe workplace starts with a robust training program. After all, one can only expect specific gains if the right training is available. That characteristic of specifics, however, often acts as the drop-off point. The training needed might not be available or, sometimes, has never been developed. As a result, the more specific the task, the more difficult it is to find an appropriate curriculum to offer results. With the technological revolution at hand, strides are underway to meet these needs, and Precision Drilling has found a path to success with SynergyXR’s extended reality training program.

According to Mads Troelsgaard, CEO and cofounder of SynergyXR, Extended Reality (XR) is the gateway to the metaverse based on the combination of Virtual Reality (VR), Augmented Reality (AR), and Mixed Reality (MR).

“At SynergyXR, we have been working with these technologies for over 15 years, and our first VR offshore training program occurred in 2010,” says Troelsgaard. “In 2018, we saw a common need by all customers where they wanted the ability to create content themselves without having to use external consultants for creating these trainings and onboarding and experiences in AR and VR.”

After the original version of SynergyXR entered the market in 2020, the energy sector realized the platform’s value. Training for highly specialized and specific tasks could be made available.

“This platform allows the user the ability to train better,” says Troelsgaard. “Better trained people help avoid injuries and incidents, thereby improving a safety culture.”

The Light Bulb Illuminates

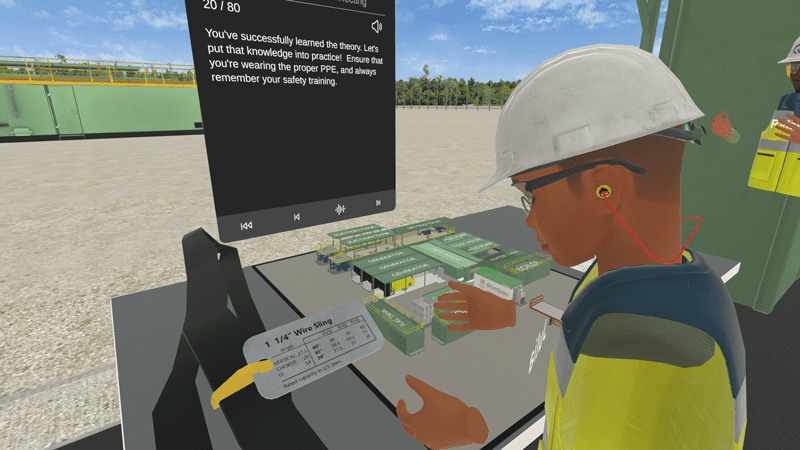

The SynergyXR platform is the foundation for specific training modules to be built upon and enabled for use. Just like a VR video gaming system, the user dons the headset and is thrust into a virtual reality of whatever the company wishes to portray. The user undergoing the training acts out the steps and actions in real time to complete the specific task both safely and accurately in that software-provided virtual world.

With the ability to customize and create a select reality, Precision Drilling, a global leader in onshore drilling, identified the opportunity to develop critical task training specific to the company’s individual work applications. Like a light bulb turning on, the company realized it could expose its staff to essential tasks, educate those individuals on correct work practices, and allow them to walk through the process without enduring harm through incorrect action.

“PowerPoints and guidebooks were not getting the desired results,” says Russell Whitney, Industrial Internet of Things (IIOT) Product and Program Manager at Precision Drilling. “We needed to try something new and saw an opportunity with SynergyXR and their hunger to innovate.”

In combination with the need to provide a specific type of training, Whitney additionally explains the necessity for change to meet the needs of the next generation of energy professionals. As the industry evolves, so does the ideal worker.

“We also wanted to develop and enhance a training program not only developed for the new type of worker entering the workforce, but to make sure we give them what they need to go out and work safely in the field,” says Whitney.

Applying the Platform to the Process

“We are early in this space and VR doesn’t take the place of historical training and orientation,” says Rob Houston, Vice President, Rig Technology and Service Delivery at Precision Drilling. “Coming from the rig tech side, we wanted to focus on modules laying on top of each other on a rig.”

Precision Drilling remains committed to making sustainable drilling a reality using its Evergreen™ suite of eco-friendly solutions. The company welcomed grid-powered drilling technology as part of its path to net zero emission. It was through this process that Precision Drilling chose to marry with SynergyXR’s foundation platform. Battery placement reigns as a critical task associated with Evergreen. As a result, the entire process of placing the battery, making connections, and initiating the startup have all been built upon SynergyXR’s platform.

Donning a headset and gripping hand controllers, the individual enters Precision Drilling’s virtual reality to initiate the process. There, the user sees a visual mirror of themselves overlooking the drilling rig footprint. The Evergreen™ module can be handled and placed in the proper location. A series of guidance panels guides the user throughout the process, including crucial details like sling tags and important load information.

In this simulated reality, the user goes through each step of placing the Evergreen™ storage unit, including the rigging and offloading from the truck at delivery. As the user continues the virtual walk through those steps, their mirror image addresses the cable connections and the electrical panel for startup. A procedure overview populates and provides the necessary guidance to complete the process safely and successfully.

These multi-layered steps, supported with guidance and endured in this virtual reality, allow for the best rendition of on-the-job exposure without the potential of encountering injuries or incidents, serving as the next best thing to being there in the present. The process allows the user to undertake the critical task and learn from mistakes made without being overshadowed by actual consequences.

According to Houston, Precision Drilling has deployed 15 battery energy storage systems on its drilling rigs. Detailed pre-startup meetings take place via Microsoft Teams, with participation from Evergreen™ Systems’ managers, members of leadership, and technicians. Staging and setup tasks have been deployed through the SynergyXR platform, but the company’s usage of the technology will intensify with the next battery deployment.

“The next litmus test is the next battery to be deployed where we levy this training as the single source piece,” says Houston.

Houston and Whitney see exciting times ahead and what can be accomplished through this new learning process. However, they agree it has a significant use not as a stand-alone tool, but one that intensifies and completes contemporary learning, such as classroom settings with live instructors, as well as an extension of virtual learning and computer-based training.

“Our intent was never to replace traditional training and the robust training we have,” says Whitney, “but this is a way to engage the different people coming into the industry.”

Academia Weighs In

SynergyXR’s success with Precision Drilling and other companies like Maersk has caught the attention of university oil and gas safety champions. Dr. Faisal Khan, Director of the MKO Process Safety Center at Texas A&M University, sees the added value of applying the SynergyXR platform to existing training curriculums.

“We have education programs to train and certify students to work safely in the industry,” says Khan. “SynergyXR brings the value of allowing the student to see the visual aspect of loss, which is a critical piece. It highlights the importance of not repeating the behavior and learning from failures.”

Khan believes integrating extended reality into the classroom would intensify the current training programs. With the ability to borrow the platform instead of recreating it for classroom application, he hopes the SynergyXR platform and its customer solutions can be implemented in the classroom on a trial basis by 2025. This type of partnership demonstrates the spirit of the MKO Process Safety Center.

“We collaborate, cooperate and work with our industry partners to help educate, train and solve challenges related to safety.”

Seeing Is Believing

Designing, implementing and managing an effective safety program can prove challenging because it requires meeting numerous considerations. Logistics often plague companies when trying to congregate employees in one location simultaneously. Additionally, communicating the significance and pressure of potential injury and incident typically becomes daunting because, in most cases, seeing is believing.

The goal of training an individual on the seriousness and potential criticality of life-and-death scenarios has often fallen short because there are no means to demonstrate this aspect or because its importance fades in comparison to timelines and the pressure to complete specific tasks.

SynergyXR provides a platform that addresses those concerns. Precision Drilling has capitalized on its abilities by using the technology to train its workforce on critical tasks. The technology not only communicates the steps to complete the task, but also allows the worker to do so in an alternate reality where, if a mistake is made, the consequences of life and death, as well as equipment and property damage endured, do not leave a life-lasting detriment.

XR provides a positive atmosphere to train workers and teach through process application. It offers a solution for reaching a remote workforce and excites and ignites learning, much like the intended goal found in the earliest years of individual learning as children. Precision Drilling wants to build upon this commitment to learning and working safely.

“I would love to be in a world where an employee comes to Precision and asks when the next training module is coming out as opposed to the company looking at a spreadsheet and asking the employee why their training has not been completed,” says Houston. “We want our people to be excited about learning how to safely execute critical tasks.”

Nick Vaccaro is a freelance writer and photographer. In addition to providing technical writing services, he is an HSE consultant in the oil and gas industry with twelve years of experience. Vaccaro also contributes to SHALE Oil and Gas Business Magazine, American Oil and Gas Investor, Oil and Gas Investor, Energies Magazine and Louisiana Sportsman Magazine. He has a BA in photojournalism from Loyola University and resides in the New Orleans area. Vaccaro can be reached at 985-966-0957 or nav@vaccarogroupllc.com.