When talking about advances in oil and gas technology, we would be remiss if we didn’t discuss unconventional methods of oil and natural gas recovery and the ways in which they could benefit the U.S. economy. There are always the tried and true methods – foolproof and with little-to-no risk. With these standard approaches, there have been and continue to be advances that make them more efficient and cost-effective. But it makes you wonder, what else is out there? What other innovations are there that could potentially revolutionize the oil and gas industry and the recovery of these vital resources? Companies, universities, researchers, government agencies, etc. would all benefit from the exploration of alternate methods. The problem with unconventional methods is that it’s a risky operation to research them and without proven success, it is hard to find backing.

The U.S. DOE (Department of Energy) has recognized the extreme benefits associated with this kind of research and they have generously chosen to invest approximately $30 million dollars to boost unconventional oil and natural gas recovery. In January 2018, they announced the selection of six projects, selected under the Office of Fossil Energy’s “Advanced Technology Solutions for Unconventional Oil and Gas Development” to receive the federal funding. The field projects that were chosen are currently producing less than 50,000 barrels per day using unconventional plays. According to the DOE press release dated January 3, 2018, “The newly selected projects will help us master oil and gas development in these types of rising shale, along with bolster DOE efforts to strengthen America’s energy dominance, protect air and water quality, position the nation as a global leader in UOG (unconventional oil and natural gas) resource development technologies, and ensure the maximum value of the nation’s resource endowment is realized.”

The DOE took careful measures in selecting the six recipients of this award. Without further ado, they are as follows:

- C-Crete Technologies, LLC – Hexagonal Boron Nitride Reinforced Multifunctional Well Cement for Extreme Conditions

- The Institute of Gas Technology – Hydraulic Fracture Test Site II (HFTS2)

- Texas A&M Engineering Experiment Station – Eagle Ford Shale Laboratory: A field Study of the Stimulated Reservoir Volume, Detailed Fracture Characteristics and EOR Potential

- The Trustees of the Colorado School of Mines – In-Situ Applied Coatings for Mitigating Gas Hydrate Deposition in Deepwater Operations

- University of Louisiana at Lafayette – Tuscaloosa Marine Shale Laboratory (TMSL)

- Virginia Polytechnic Institute and State University – Field Laboratory for Emerging Stacked Unconventional Plans (ESUP)

C-Crete Technologies (Stafford, TX)

C-Crete Technologies is developing a proof-of-concept hexagonal boron-nitride/cement composite that will be developed and tuned to offer optimum slurry formulation and rheological properties, and the best hybrid nanostructure. This is the next generation of well cementing with multifunctional, high-performance characteristics. This includes mechanical, thermal, rheological, and durability properties – to prevent offshore spill and leakage at extreme high temperature, high pressure, and corrosive conditions. Not only is this composite cost effective, it also has no toxicity, and easily integrates to existing equipment and facilities.

This product will provide a new tool in next-generation well cementing technologies and multifunctional materials for other applications, such as unconventional resources, geothermal wells, and thermal recovery wells. The formulation, materials, and recommended procedures will be available for use by offshore communities. This will prevent offshore spill and leakage at extreme conditions, it increases cost-efficiency and production, mitigates risk over the productive life of the wells and improves environmental and worker safety.

The Institute of Gas Technology (Des Plaines, IL)

This project will conduct a field-based hydraulic fracturing research program in the Delaware Basin portion of the Permian Basin in West Texas. The Permian is one of the most prolific oil and natural gas geologic basins in the U.S. The problem lies in the application of a uniform fracture stimulation design to all stages with no consideration for geological variations along the wellbore. The result is an inefficient use and a costly waste of water and energy. Optimization of the fracturing process requires an understanding of the cause and effect relationship between fracturing parameters and local geological properties at a given location along the wellbore. The overarching goal of this project is to understand and define the relationships of shale geology and fracture dynamics using detailed field data that includes coring of the fracture domain.

This project will advance hydraulic fracturing technology, optimize well spacing, and mitigate environmental impacts of shale development operations. The research will advance our understanding of the hydraulic fracturing process in shale reservoirs, thus enabling the design and execution of effective fracture stages that significantly contribute to production. Improved design and execution of fracture stages will also reduce the number of future infill wells drilled and reduce water volume and energy input. Drilling too many wells results in a waste of resources, such as water, steel casings and other infrastructure, while adding to emissions issues and land footprint. Drilling too few wells, from the perspective of well spacing, leaves valuable resources in the ground. Research results from this project are expected to have positive impact on economic, environmental, and resource recovery factors.

If the resulting optimization leads to a resource recovery increase of 1 percent, an additional 1.6 billion barrels of oil could be recovered from the Permian.

Texas A&M Engineering Experiment Station (College Station, TX)

The field-based research for this project will be conducted in the Eagle Ford Shale Formation with the purpose being to improve efficiency of oil and gas recovery from hydraulically fractured horizontal wells. The enabling technology creating tremendous growth in oil and gas production in the U.S. in the past decade has been the result of multi-stage hydraulic fracturing of unconventional reservoirs, implemented in tens of thousands of wells. Much of this technology, however, has resulted from expensive trial and error approaches applied in the field. In spite of thousands of wells drilled and hydraulically fractured and billions of dollars spent, the industry still looks for answers that lie within fracture systems concerning stimulated reservoir volume and the complexity of the created fracture system. Without this basic knowledge of the true stimulated reservoir volume, operators cannot optimize key development parameters, including well placement and vertical placement of laterals.

If this project is successful, it will provide key insights into the fracture stimulation and EOR (Enhanced Oil Recovery) processes. It will develop new methodologies and operations experience for optimized production of oil from fractured shale, which would allow for more production from fewer new wells with less material and energy use. While the proposed project is site-specific to the Eagle Ford formation, the resulting knowledge will be able to be applied to other unconventional plays, or other subsurface applications, such as unconventional oil and gas recovery and tight gas sand reservoirs. By using the newly-developed and comprehensive monitoring solutions, unprecedented and comprehensive high-quality field data will improve scientific knowledge of not only the hydraulic fracturing process, but re-fracturing, and subsequent huff and puff gas injection as an EOR method.

The Trustees of the Colorado School of Mines (Golden, CO) & Oceanit Laboratories, Inc. (Honolulu, HI)

Colorado School of Mines (CSM) and Oceanit Laboratories are developing a novel ‘hydrate-phobic’ coating for deepwater well environments that will improve safety, cost, and component life during operations. The ability to mitigate gas hydrate blockages in flowlines is critical to ensure the safe and economic operation of deepwater facilities, to extend the life of the field, and to minimize product loss. Prevention of hydrate blockages will mean operating in a safer and more cost-effective environment, as current mitigation costs can exceed $1M per mile of pipeline.

A coating capable of repelling deposition and preventing hydrate build-up – that can be applied in-situ to existing flowline facilities – would represent a breakthrough over the current state-of-the-art, mitigating the severe production, environmental, and safety issues that this deposition can cause during operations, including catastrophic blowouts and sustained leaks. CSM and Oceanit are further testing this novel coating against the adhesion and deposition of waxes and asphaltenes to investigate the broader capabilities of the coating under field conditions, where these solids will accumulate to cause restricted flow problems in the flowlines. This research represents a novel, cost-effective solution to unresolved flow assurance challenges that would ultimately lead to major fundamental breakthroughs in gas hydrate and related solids engineering.

“Novel, nanocomposite-based surface treatment technologies, such as the ones being developed by Oceanit can have a profound impact on the efficiency, safety and therefore environmental impact of production operations. In bringing this technology to the market, Oceanit is proud to partner with CSM, who brings decades of expertise in hydrates and flow assurance testing to the effort. The funding support from U.S. DOE National Energy Technology Laboratory made this partnership and maturation of the technology possibly. We are excited to advance a field-deployable solution to a very long-standing challenge faced by the industry today.” – Dr. Vinod Veedu, Oceanit Laboratories, Director of Strategic Initiatives

“Gas hydrate plugs in flowlines present a major economic and safety concern to the oil and gas industry during subsea production. The ability to prevent hydrate deposition is using coatings is especially critical to mitigating pipeline blockage and ensuring safe and efficient production. “– Dr. Carolyn Koh, Colorado School of Mines, Director, Center for Hydrate Research

University of Louisiana at Lafayette (Lafayette, LA)

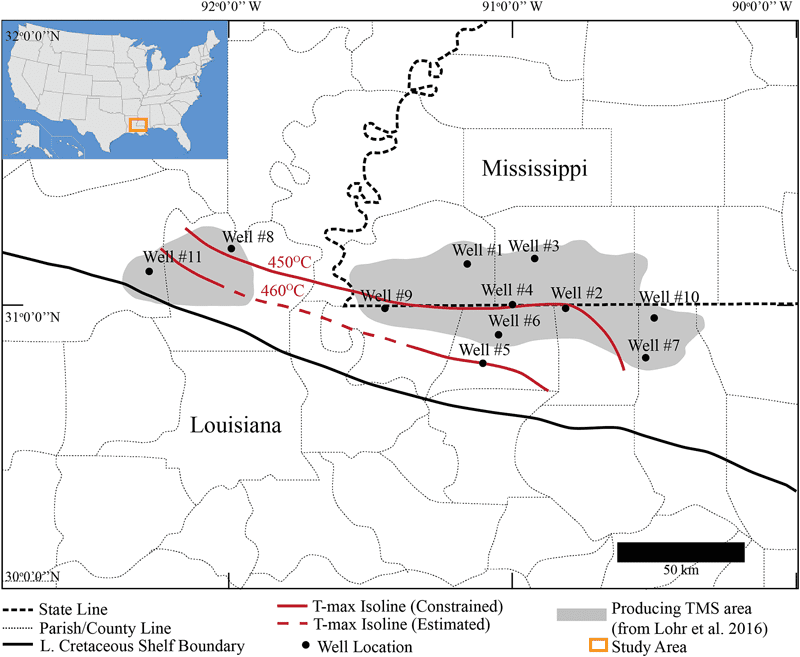

Tuscaloosa Marine Shale Laboratory (TMSL) is an excellent example of collaborative effort between the federal government (DOE, Las Alamos National Lab), several academic institutions (University of Louisiana at Lafayette as the lead, University of Missouri Science and Technology, University of Oklahoma, and University of Southern Mississippi) and private sector (Goodrich, ExxonMobil, Signal, and Helis) to support energy production and development projects. The goal of TMSL project is to bring all stakeholders together in a synergistic approach to unlock significant estimated unproved hydrocarbon resources of Tuscaloosa Marine Shale, as a major challenging shale play, in economic and environmental-friendly manner. TMSL is a multidisciplinary team of more than 30 faculty and research assistants with background in petroleum engineering, geology, geophysics, and socio-economics studying the key issues in reservoir quality and completion quality of TMS.

The University of Louisiana, Lafayette is home to a TMS virtual laboratory with a significant amount of whole cores, slabbed cores, cuttings, and data for TMS wells. The team recently published the results on the mineralogy and geochemistry of 11 TMS wells at “Marine and Petroleum Geology” journal: “Heterogeneity of the Mineralogy and Organic Content of the Tuscaloosa Marine Shale, Marine and Petroleum Geology. Vol. 109, Pages 717-731” The virtual laboratory will conduct testing and analysis of various properties of rock and formation fluids from the TMS to determine sources of the wellbore instability issues, improve formation evaluation, the role of geologic discontinuities on fracture growth and shale creep. University of Louisiana – Lafayette also plans to investigate the application of stable CO2 foam and super-hydrophobic proppants for improved reservoir stimulation, as well as to better understand the nature of water/hydrocarbon/CO2 flow in a clay and organic-rich formation.

The TMS has been estimated to contain 7 billion barrels of recoverable light, sweet crude oil, while its current total average production is only about 3,000 barrels of oil per day. Over the years, operators have been unsuccessful in the TMS play, in part due to its clay-rich nature which makes it sensitive to water. Improved understanding of the TMS, along with public scientific assessment of new approaches for developing the play, will expand and accelerate industry efforts to cultivate this resource with minimal environmental impact.

Virginia Polytechnic Institute and State University (Blacksburg, VA)

The Central Appalachian region is host to an abundance of hydrocarbon resources including coalbed methane, shale, and other unconventional reservoirs. Many of these plays are vertically stacked such that a single well or group of wells in close proximity can produce simultaneously from multiple reservoirs. Because many of these reservoirs produce less than 50,000 BOE (Barrels of Oil Equivalent) per day and can thus be classified as ESUPs (Emerging Stacked Unconventional Plays). The project is designed to improve characterization of the multiple emerging unconventional pay zones that exist in the established Nora Gas Field through the drilling and coring of a vertical stratigraphic test well up to 15,000 feet deep.

This project will evaluate and quantify the benefits of novel completion strategies for lateral wells in the unconventional Lower Huron Shale. A major research objective of the project is to characterize the geology and potential deep pay zones for Cambrian-age formations in Central Appalachia. A second major research objective is to evaluate and quantify the potential benefits of novel well-completion strategies in the emerging (and technologically accessible) Lower Huron Shale. The benefit of this research will reduce surface footprint, infrastructure requirements and development costs by combining best practices, state of the art technology and effective outreach to carefully develop these resources.

Conclusion

The motive behind the unconventional methods research consists primarily of three objectives:

- Improving understanding of the process involved in resource development

- Advancing technologies and engineering practices to ensure these resources are developed efficiently with minimal environmental impact and risk

- Increasing the supply of U.S. oil and natural gas resources to enhance national energy dominance and security

The oil and gas industry is advancing by leaps and bounds, to be progressive, the unconventional must be explored. The DOE assisting in these efforts is displaying their commitment to the industry and the U.S. economy as a whole. It will be interesting to follow these projects and see where the end result leads.

Sarah Skinner is a graduate of Louisiana State University with a degree in English. She has been a technical writer and editor in the oil and gas industry for over ten years in Houston and in Louisiana. She currently works as a technical writer for a pre-cast concrete construction company in Louisiana that builds blast-proof buildings for petrochemical plants.