The oil and gas industry is no stranger to uncertainty, but with incongruity of supply and demand, organizations have found a game changer in getting better margins through efficiency rather than overproduction. The companies in the industry that are coming out on top are those who are embracing digitization (the automation of existing manual and/or paper-based processes). While collecting, analyzing and effectively using massive amounts of data (digitization) is not new, not even to the oil and gas industry, it is still not vastly implemented on an end-to-end scale.

Improving operations through analytics and project control systems is proving to be essential industry-wide now that high energy prices aren’t necessarily there to blanket the cost of inefficiencies.

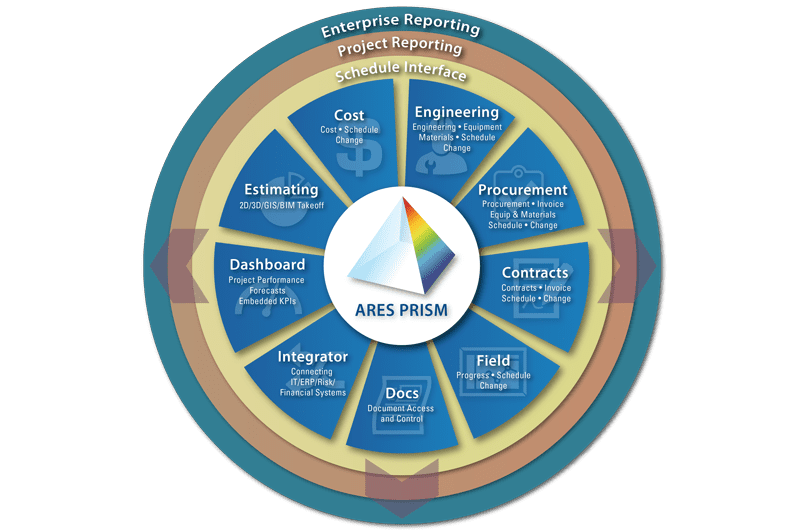

One such solution that has seen a shift in the oil, gas and chemical industry from holding on to old processes and tools to embracing digitization and automation is ARES PRISM. ARES PRISM is enterprise project controls software that has been swept up by many industry-leading Gulf Coast companies in recent years.

“Our project controls software, ARES PRISM, lets companies analyze data in ways they’ve never been able to in the past; saving them valuable time and money,” Geoffrey Stubson, Chief Financial Officer of ARES Project Management, LLC, said. “That initial fear of implementing a new solution across an organization is often quickly replaced by relief when they witness the increase in operational efficiency, productivity, reliability and predictability after deployment.”

McKinsey & Company estimates that effective use of digital technologies in the oil and gas industry could cut capital expenditure by up to 20 percent and improve global cash flow to around $300 billion by 2025.

At implementation, oil and gas companies often have the challenge of dated legacy systems and equipment, and a huge number of suppliers. In fact, that is how ARES PRISM began– ARES’ project managers needed a better software solution than anything that was available on the market. When organizations implement ARES PRISM, they have a team of ARES PRISM project management experts helping them to roll-out the software. They are experienced in these common industry challenges and implementing and deploying ARES PRISM in ways that make their clients a more well-oiled machine.

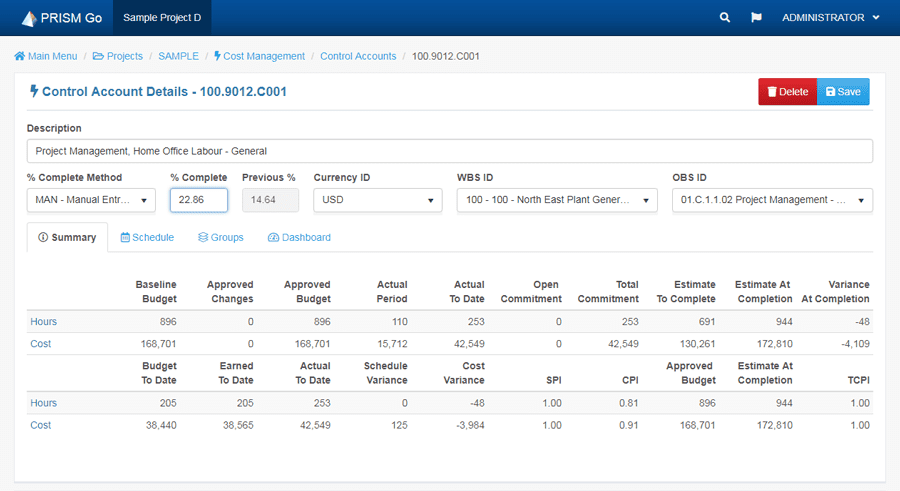

Project controls software helps to solve the oil and gas sector’s pain points surrounding inefficiency: relying on error-prone spreadsheets, the increasing complexity of projects, time-consuming reporting at month’s end, change control and change management, and the lack of visibility into projects. When organizations successfully deploy an enterprise project controls software, they transform their previous manual processes to smarter, digitized processes. Digitization allows for more convenient, easier and superiorly utilized labor that gains a better planning process.

With proper project controls established, project planning has predictive analytics and forecasting so that these organizations are able to anticipate and better respond to shifts in the market, company or project. With the constant flow of real-time data that can be processed continually, teams and stakeholders can make better informed decisions faster.

In the last decade, many companies in this sector were exploring digital solutions to keep up and remain relevant, but it was not on a widespread, organizational scale. At the time, the effort and cost for a company to implement a digital transformation was not highly incentivized while energy prices were high. However, once oil prices began falling in 2014 when production started to outpace demand, corporations would have been wise (and some were) to stop shirking digitization and embrace it fundamentally.

A 2015 survey conducted by Cisco Consulting Services of 550 oil and gas company professionals (upstream, midstream and downstream professionals) in 14 countries found that nearly 50 percent of respondents reported that data quality was the number one area of operations that needed improvement in order to make better use of IoE (Internet of Everything) technologies. IoE refers to the networked connection of people, process, data, and things. The survey identifies intelligence from data as the key area needed to improve operational efficiency, and data analytics as the number one IoE driving force for faster, better decision-making.

With this realization being recognized by 48 percent of oil and gas respondents at the time, it is not surprising that they named “operational efficiency of existing projects or reserves” as the top area of increased investment over the next two years. The survey also found that leaders need to improve operational efficiencies and asset life to stay competitive without cutting costs with layoffs and project cancellations.

The respondents understood that connecting “things” is a necessity, but that the true value lies in the intelligence of extracted and analyzed data from the “things.” This extracted  intelligence allows companies in the oil and gas industry to drive business and operational transformation. Enterprise project management software like ARES PRISM is the centralized system that houses all the cost, schedule, and other integral systems’ data for analysis and reporting.

intelligence allows companies in the oil and gas industry to drive business and operational transformation. Enterprise project management software like ARES PRISM is the centralized system that houses all the cost, schedule, and other integral systems’ data for analysis and reporting.

When implemented throughout an organization, digitization provides the means to completely review and re-evaluate processes and operations, including inventory and labor needs. Project controls software solutions embrace the way technology is moving with the IoT via integration and makes companies more agile. Bringing real-time data into one robust system effectively helps to destroy data that was once siloed.

Integrating dependable project controls data in one centralized system is delivering new efficiencies and transforming oil and gas companies and their margins. By connecting IT systems, ERP systems, financial systems, legacy systems and business processes, companies are able to orchestrate data flow that supports business goals.

Discussing the survey in an interview with Rigzone in 2015, Nicolaas Smit, director for the global energy industry at Cisco Systems, said, “The industry has made great progress on digital energy, but now it’s time to build on that foundation to make the industry hyperaware, predictive and agile using enterprise-level data management tools.”

Since then oil, gas, and chemical firms have been jumping onboard with enterprise-level data management solutions like ARES PRISM, which has seen a major rise in clients of this sector in the Gulf Coast area.

“We’re happy to be a part of the ongoing digital transformation in this major hub. Houston and the Gulf Coast area is huge, but the oil and gas sector seems to be pretty tight-knit professionally,” Geoffrey Stubson, Chief Financial Officer of ARES Project Management, LLC, said. “One O&G firm implements ARES PRISM then talks about the quick return on investment and the gains they are experiencing to a former colleague or friend at another company, and the word-of-mouth spreads.”

Enterprises are now deploying solutions that fit their needs with data and project management software systems such as ARES PRISM, rather than trying to make the faulty legacy systems and spreadsheets work. They are ridding their organizations of disparate systems and processes, along with the risks they posed. Despite being a COTS (Commercial-off-the-Shelf System), when implemented wholly throughout an organization, this software solution destroys data silos and becomes the ultimate in-house system since it is capable of integrating bi-directionally with other already in place systems.

Unlike other market solutions, ARES PRISM integrates financial, process, project, and organizational information into one dependable, robust solution. Once data is captured, it limits data leakage that can hinder operational and business decisions. It helps end information leakage types like data integrity not being maintained, data not being stored, data not being accessible, data not being analyzed, and data that is not communicated.

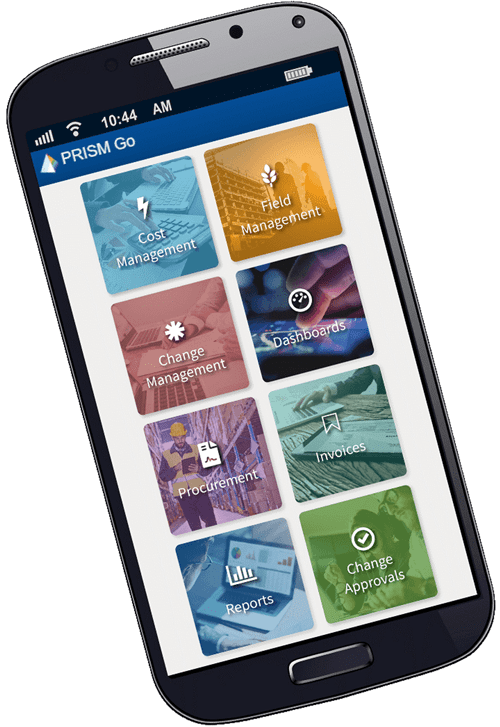

With a powerful platform like ARES PRISM, oil and gas companies can scale-up their programs. The tools and capabilities required for digitizing change and risk management are built-in. If an oil and gas firm hasn’t begun to digitize, it is not too late to start the transformation. According to Ernst & Young, the time is now thanks to “the industrial internet, advanced analytics, cloud storage and increasingly reliable mobile communications [that] enable the potential for digital to transform the oil and gas industry.”

Photos courtesy of ARES PRISM

McKinzie Pack is a content specialist for project controls software tool, ARES PRISM. With its growing presence in the Houston market, McKinzie has seen many organizations benefit from the world-class integrated project management software. ARES PRISM manages the complete project lifecycle of capital projects to lower cost, mitigate risk and improve overall project performance. It is utilized across all major industries including the oil and gas, energy, engineering and construction. ARES PRISM has won numerous awards recently, including “Global Award for Project Controls in a Mega Project” at the Project Controls Expo UK and “Excellence in Cost Management” at the AACE International Conference.