Water plays a key role in the production of oil and gas. In fact, unconventional oil and gas exploration typically relies on vast amounts of water. With water being utilized so frequently in the oil and gas industry, it is important that water is used efficiently and wisely during production processes, as to not disturb or deplete the natural resource. With water management and conservation increasingly becoming a larger topic in the oil and gas industry, more oil and gas companies are developing or investing in better drilling practices and green technologies.

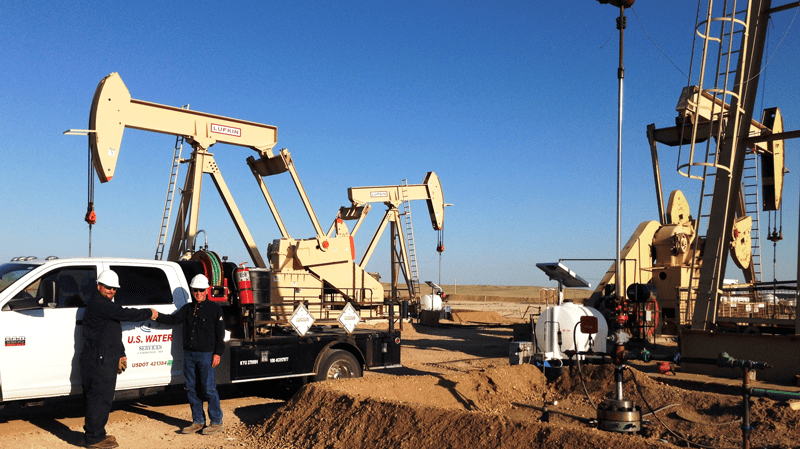

U.S. Water, headquartered in Minnesota, provides water and process treatment and environmental solutions to a variety of industries, including the oil and gas industry. Their mission is to provide cost-effective integrated solutions utilizing engineering, equipment, chemistry, and other elements to improve customer operations and promote water conservation. David Schneider, Senior Business Development Manager of Energy Services, and Gene Hatcher, Director of Energy Services, shared their thoughts on the importance of water management in the oil and gas industry, U.S. Water’s initiatives for water treatment and better oil production, and how technological solutions and eco-conscious practices have been improving water management efforts.

When asked about the importance of water treatment in the oil and gas industry, Schneider and Hatcher discussed the shortage of water in the industry and therefore, it is crucial that proper water reuse and management be implemented for the sake of the industry’s future. They explained that with the limited supply of water, it is imperative that water is used for the proper application. “The water being applied to oil and gas systems must be clean of solids, bacteria and other impurities as to not contaminate the reservoir, well and other production equipment,” agreed Schneider and Hatcher.

Schneider and Hatcher were asked to explain how U.S. Water’s products enhance the productivity of oil plants. “To help clean the water before it enters the system, U.S. Water offers a process and production chemistry line that is designed to improve well injectivity and increase disposal volume,” said Schneider and Hatcher. “Our products clean up and prevent deposition in gathering and transportation lines.” They also shared how in processing facilities, their solutions are able to remediate unwanted precipitates by preventing system fouling and plugging. “Our automation and monitoring programs provide system operational data to ensure safe, consistent chemical programs,” said Schneider and Hatcher.

Schneider and Hatcher were asked how much they believe the oil and gas industry has improved in water conservation and oil recovery in the last 10 years. They shared that while water conservation and oil recovery efforts in the oil and gas industry are not 100 percent perfect, there have been major improvements to water, overall. “The majority of companies put forth R&D efforts in the conservation of water and correct application for water management,” explained Schneider and Hatcher. They added that now, there is a better understanding of how removing large amounts of water from the ground impacts the environmental climate of a particular area. “Continued research and development efforts have progressed water management and conservation initiatives. Maximized oil recovery has kept the water cleaner than it has ever been,” stated Schneider and Hatcher.

In addition, Schneider and Hatcher were asked about the improvements U.S. Water has contributed over the years to the oil and gas industry, regarding upstream production, pipelines, and salt water disposal. They explained that U.S. Water has helped reduce gas consumption and treatment costs and increase site safety through their efforts. “We’ve provided proper application for water systems, keeping water as pure as possible through advances in chemicals such as emulsion breakers, scale inhibitors, biocides, surfactants, and other chelating chemistries,” shared Schneider and Hatcher. “We are also looking into improvements for equipment and engineering control.”

Schneider and Hatcher were then asked about any new products or technologies they’re currently working on. They shared how they are currently working on alternative frac chemistries to lower dose rate and increase performance. “We are working on next generation water enhancement products, pipeline cleaning chemistries, gas processing and SWI / SWD injectivity chemistries,” Schneider and Hatcher further explained.

When asked why they think it is important for oil and gas companies to invest in solutions that aid in water management/treatment, Schneider and Hatcher explained that water must be measured and managed, like any other production input or byproduct, or the sources of water will become limited. “The industry’s water consumption and environmental practices are subject to regulator, shareholder, and community scrutiny,” expressed Schneider and Hatcher. “Not only can prioritizing water management show environmental stewardship, it can mitigate risks and improve operations.”

When asked what products they’d like to see developed to aid in water treatment and conservation or oil recovery, they shared how they’d like to see the further advancement of water reuse chemistries. “We should continue to look at alternative water sources, such as industrial waste water being used for oil and gas applications, after being cleaned and converted for fresh-water use,” explained Schneider and Hatcher. Schneider and Hatcher further noted the importance of seeking alternative means of lowering the cost of water treatment as water becomes ever scarcer.

Tonae’ Hamilton has been a contributor and associate editor to the magazine for two years. She has been writing professionally for almost four years. In her free time, Tonae’ likes to spend time with her three pets, cook, and binge-watch Netflix shows. Tonae' has a Bachelor of Arts in Communication from McDaniel College.