The oil and gas industry is dangerous because of the hazardous activities that take place at the worksite. It’s the responsibility of employers in this industry to recognize and control the potential hazards as much as possible, which means creating a workplace safety culture and providing the right equipment for the job to ensure that the risk of injuries and fatalities are minimized as much as possible.

Oil and Gas Risks

Oil and gas workers are at an increased risk of exposure to struck-by and fire hazards. Moving equipment and vehicles are common—being struck by falling, flying, swinging, or rolling objects causes three out of every five fatalities in these industries. Heavy moving objects have the potential to strike workers and pedestrians alike and cause injury or death. Accidents can be minimized by workers who are aware of their surroundings. If they are working where they’re supposed to, and talking to equipment operators, they still need to wear personal protective equipment (PPE) that can protect them from impacts and other injuries on the job. They also need to be seen, which can be hard in an industry where dark environments aren’t uncommon.

Oil and gas workers are exposed to fire hazards as well. They are also exposed to explosive gases and particles, electrical hazards, sparks, and flames, and in the event of an accident, can suffer from severe burns, blindness, broken bones, and death. Flash fires (which spread rapidly when vapors or particles ignite and explode) and electric arc flashes (which occur when electrical currents pass through ionized air from an electrical fault) are both risks in the oil and gas industry, which makes it one of the top markets for FR apparel. Most of the severe burn injuries and fatalities on a job site happen when non-FR clothing is worn in an accident and burns once ignited.

You can minimize the chances of an accident occurring, but can’t take that likelihood away completely. PPE exists to decrease the chance of a tragic accident, but also to increase the survivability of any accidents that do happen. Given that the oil and gas sector is full of safety hazards—the flammable materials, work methods and processes, and environment all present a danger to workers—oil and gas workers need to wear FR clothing. OSHA released a memo in 2010 listing the activities where workers must wear FR clothing, but many employers are starting to require PPE to be worn at all times as a standard uniform.

Hi-Vis and FR Clothing Recommendations

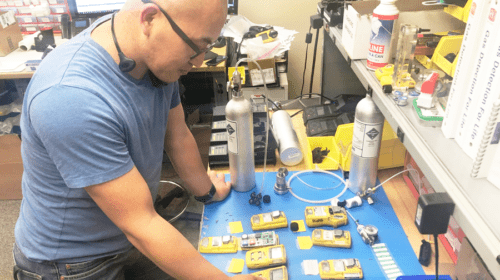

High-visibility clothing, that is also fire-resistant, can help protect employees from struck-by and fire hazards and should be part of basic PPE. All hi-vis and FR clothing must be labeled appropriately and compliant to the job that you’re using them for—never assume that protection is a guarantee. Also, don’t assume that putting on hi-vis clothing over your FR clothing will protect you from flames unless the vest is also FR-rated because the materials need to be treated differently. The same goes for jobs where arc flashes are a hazard. While arc flash clothing is also fire resistant, FR and AR (arc-rated) clothing is rated for different hazards and therefore more appropriate to certain jobs.

The apparel you’ll need depends on the job that you’re doing—not all fire hazards are the same, and not all clothing will meet all standards. If you’re in charge of acquiring PPE for your workers, make sure that what you buy complies with the standards and regulations appropriate for your line of work. Fire-retardant materials can be made into vests, shirts, jackets, pants, coveralls, hoods, and other clothing designed to self-extinguish or resist ignition, be visible even in dingy working conditions, and stay comfortable in any kind of weather or worksite.

The proper care of your FR equipment is crucial, particularly for the oil and gas sector. Not only is this an industry focused on reducing costs and expenses, but it’s also a dangerous one, and only gear that’s properly maintained can retain maximum fire hazard protection for a long time. Investing in high-quality garments that are resistant to abrasion and easy to clean means that you won’t have to replace your gear as often and it will remain safe for its life. There are commercial laundry programs available that can effectively remove flammable hydrocarbon contamination. Make sure that you don’t treat your gear with chlorine bleach or wash it with non-FR clothing. If you have FR-treated cotton fabrics, don’t wash them in hard water, as this can diminish their effectiveness.

FR gear should be inspected on a regular basis to ensure that it’s still fit to be worn. Garments that are thin or worn in some areas aren’t going to offer optimal thermal protection, and any cuts or holes will reduce the gear’s ability to protect the wearer. Either repair damaged gear with flame-resistant like materials or replace it completely to make sure that your workers are safer for longer.

Take your time reviewing your oil and gas safety equipment options and use a trusted supplier to help you through the process and answer your job safety questions.

Rick Pedley, PK Safety’s President and CEO, joined the family business in 1979. PK Safety, a supplier of occupational safety and personal protective equipment, has been operating since 1947 and takes OSHA, ANSI, PPE, and CSA work safety equipment seriously. PK Safety's customer service can be reached at 800-829-9580 or online at https://www.pksafety.com/contact-us.