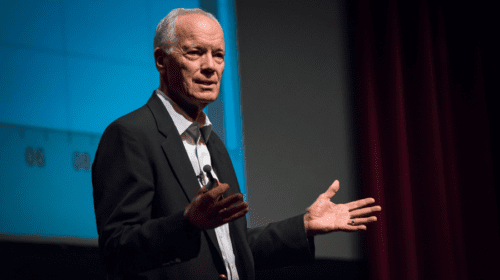

Lynn Helms is considered North Dakota’s top regulator, serving as director of the North Dakota Industrial Commission Oil and Gas Division since July 1998 and director of the Department of Mineral Resources since July 2005.

He earned his B.S. degree in engineering from the South Dakota School of Mines and Technology in 1978, but his oil field career began as a roughneck in 1976 working summers and school holidays. After graduation, Helms worked for two years as a production engineer for Texaco in all of the producing areas of Montana.

In 1980, Helms joined Amerada Hess in Williston, N.D. While in Williston, he worked as a production engineer, reservoir engineer and asset team leader on projects in Abu Dhabi, Alaska, Arkansas, Louisiana, Mississippi, New Mexico, North Dakota, Texas and Wyoming.

In addition to his day-to-day duties, Helms routinely makes the rounds updating towns, counties and organizations on the state of the Bakken.

The recent Shale Revolution has directed the spotlight in energy on North Dakota. While Texas remains the oil king, North Dakota’s recent rise and media attention is warranted due to the state’s entrance into the World Class Play status. The status of world class play means a region has the commitment to infrastructure to handle the oil and gas production and the volumes to attract major players.

Lynn Helms, director of the North Dakota Department of Mineral Resources, has a direct line to energy companies and their future drilling aspirations. Recently, I sat down with Helms to discuss current energy prices, flaring, where the actual rigs are now and what the future holds for the Bakken shale play.

Jason Spiess: How are you interpreting oil prices right now?

Lynn Helms: We had an extended period of stable oil prices starting in 2011 and running through pretty much to the yearend 2014, which is unusual to have high stable oil prices. Oil prices right now are rebounding from a significant collapse. We saw in the last half of 2014 prices drop by about 60%. They are now in the rebounding phase and the only question is how quickly that happens. Is that going to be a year roughly, like happened in 2008 or 2009? Or is it going to be three years like it happened in the late ’90s, or is it 10 years like it happened in the 1980s? No one really knows, but it certainly has the characteristics of ’08 and ’09 than it does of those earlier collapses and rebounds. But we are beginning to rebound now from a significant collapse that followed almost four years of high stable oil prices.

JS: So we are not in the Jimmy Carter years with gas stamps and lines at the pump?

LH: We don’t think so. (Helms chuckles)

JS: Let’s just say it came back to $90-a-barrel by August of 2015. What would the lag time be on something like that.

LH: It’s in the neighborhood of 11 to 12 months. So even if oil was back at $90 in August, we would be looking at July or August of 2016 before rig count would really respond significantly to that. That’s because oil companies have to raise the capital, put together their budgets, put together their drilling plans and their contracts and then go out and do the work. So it takes 11 or 12 months even with a quick rebound for that to work itself through the system and translate into a rig count.

JS: Are the majority of the companies publicly owned or corporations, so they work three to five years out in the Bakken?

LH: Most of the drilling we are seeing now are publicly-owned companies. Oasis, Hess, Whiting, Continental Resources and EOG – all of them are stock companies. Some of the smaller ones are privately owned, the Emeralds and Triangles and that, but most of them are public.

JS: “Your grandchildren’s grandchildren.” That was a quote made by you that surfaced as the sound byte during the 2014 holiday season. Do you still stand behind that quote that our grandchildren’s grandchildren will still be working out in the Bakken oil fields?

LH: Absolutely, I stand behind my quote last October. And that is a really important thing for people to grasp – that even with what we are seeing today and over the past six months, which was a major price collapse, and now into the rebound phase, you have to look out at the long term. The number of wells, the amount of reserves has not really significantly changed, so by the time we return to 100,000 barrels-a-day, which is where we began the Bakken and Three Forks boom, it will take five generations, and that is if we don’t get enhanced oil recovery. I really believe we are going to get enhanced oil recovery and that will extend it beyond that 5th generation.

JS: Are there still rigs in North Dakota? Or are they being shipped to other plays? I would think that would be an indicator.

LH: That would be a major indicator. All the information we have is the rigs that have left the rig count are still in North Dakota. They have not found a home somewhere else. The emerging shale plays that would be competition for those rigs have even a higher break-even oil price than the Bakken. So on the positive side, the hardware, the equipment is still in North Dakota. It’s just been parked and is waiting for prices to come back and activity to come back.

JS: Some lucky farmer is getting new revenues in storage huh?

LH: Yes they are.

JS: You’re kidding me. Really?

LH: They are not allowed to store it on the well site. So the money that changed hands to construct that well site doesn’t cover parking the rigs. So they are going to have to go out and rent storage space for those rigs.

JS: The pricing volatility has centralized the rigs in the Bakken to four primary counties, known as the Bakken Hot Zones. What has that done with flaring?

LH: If you look at the map, you can really start to grasp the concentration of rigs that has occurred. When we started all of this, about 150 out of 190 rigs were in that circle. Still today, 123 out of a 126 are in that circle, so almost all of the rigs that have been parked have been outside that circle. This has created positives and negatives in the flaring paradigm. One thing it is creating is more multi-well pads inside that circle putting more pressure on the infrastructure in that circle and really creating some challenges because of our construction seasons with getting the pipe capacity there to gather the gas. On the other side of that, I guess, is that the infrastructure, there’s not so much build out of infrastructure in remote areas like Fortuna [N.D.], they are able to concentrate their dollars inside that circle. We are hearing from the ONEOK’s the Targa’s and Hess’s of the world that one area where there has been no reduction in capital expenditure planning is in gathering and processing. So gas gathering and gas processing capital dollars have not declined. It’s just drilling dollars and completion dollars that have declined. So they are going to concentrate the same amount of money in a smaller area. So there’s both pluses and minuses. We’ve seen a lot of technology come to the play because of gas capture. We’ve seen a tenfold increase in well site capture technology application. We’ve gone from a couple dozen of those little units operating out there to more than 250 of them. And we are seeing new technologies all the time. In fact, tomorrow, I am meeting with some folks that have the technology to convert natural gas near the well site to diesel fuel. We’ve got a technology that is being funded through the Oil and Gas Research Council to convert to methanol, formaldehyde and other chemical products that are used in the oil patch. Methanol there is huge consumption in the oil patch to keep gas gathering pipelines working. So if you can convert well site methane to methanol, you have a market right there in your neighborhood.

JS: CHS, Badlands NGL, everyone still OK with their future billions in commitments to the Bakken?

LH: We are still on track for those guys; I guess you can call them the value-added industries. Those industries are still on track to generate that next generation of value-added for North Dakota. And the reason we are excited about that is that raises what we call our job multiplier. The traditional job multiplier for oil and gas activity in North Dakota has been a 2.0. If you can bring in the value-added, like the MDU diesel refinery and the Badlands plant and CHS with their fertilizer, that goes to 3.5. So you add another 1.5 jobs for every direct oil and gas industry job, and the economic impacts of that. So we are really happy those things are still on track.

JS: You mentioned the refineries. MDU and MHA Nation in New Town, N.D., what will the impact be with diesel prices and supply and what that means to North Dakota.

LH: Well there are long-term jobs associated with the refineries. Perhaps the biggest beneficiary is going to be the agriculture industry because it is going to stabilize and lower diesel costs. They’ve struggled a little bit because at that scale it is hard to make winter blend and summer blend diesel. The larger refineries, since they are processing everything from gasoline to lube oil, they’ve got everything they need there, and they find it relatively easy to make winter blend diesel. The smaller refineries are finding it a little bit difficult. And so their start up has been postponed, but in the long run, those sized refineries – the one in New Town, the one that is proposed in Devils Lake, the one that is going into Dickinson and the one proposed in Williston – those are going to benefit the Ag industry more than anyone. We won’t see those big diesel price spikes in the spring and in the fall, when you have drilling activity, fracking activity and planting and harvesting happening all at the same time. Along with the long term jobs, we are going to help our sister industry in agriculture.

JS: Helps the pocketbook a little bit huh?

LH: Absolutely.

JS: Would these be considered “micro-refineries”?

LH: I think that would be a good way to characterize them because they are small enough that they don’t require a lot of the full blown [Environmental Protection Agency] air and water environmental impact statement permitting that goes into a major refinery. At 20,000 B/D they are a micro-refinery, and you can put multiple trains together and have a minor refinery.

JS: That seems to be the trend in the energy industry.

LH: We haven’t had a big major plant since 1976. It appears the only way to do significant refining capacity these days is multiple micro-refineries.

JS: I see in Montana there are sites being looked at too.

LH: That seems to be the trend.

JS: For the Bakken to break even, what is that magic number? I imagine it depends where the drilling activity within the Bakken takes place too.

LH: We have a map that reflects some rough pricing zones. But you can see when you compare today’s oil price – North Dakota oil price today is around $41 dollars a barrel – you can see that all of the rigs have concentrated themselves into the counties where the breakeven is $41 a barrel or less. Now those are very robust economics in and around those counties. You can still drill uneconomic wells in that area if something was wrong, but within those counties, the breakevens are significantly below today’s oil price of $41 a barrel. Now that’s going to vary from company to company and we don’t have a look into individual company’s economics, but we can look at a county-by-county basis what’s going on. It shows up in the maps and in the geography and rig counts and all of that.

JS: Are you involved with the rail much these days?

LH: Quite a bit. As you know the Industrial Commission put an order in place in late December, which [was] implemented April 1, 2015. We are answering many questions from field inspectors and operators about what that is going to look like on the ground. Also we are working with the operators to identify which facilities they are going to go the vapor-pressure route on and which facilities they are going to go the temperature pressure route on. So then we can focus our resources in the right place. For example, do I need to staff up now to handle all the vapor pressure filings? Or do I need to accelerate staffing in the field offices to check pressures and temperatures on oil fields vessels. It’s moving along nicely. I think it should be reassuring to the public there is now a standard barrel of crude oil being produced and leaving North Dakota on the rail that you can plan around.

Now you can plan your rail logistics and rail cars and all of that around this standard.

Jason Spiess is a multimedia journalist, entrepreneur and content consultant. Spiess has over 25 years of media experience in broadcasting, journalism, reporting and principal ownership in media companies. (Over 30 years experience if you count his adolescent years as a newspaper delivery boy learning the importance and logistics of daily distribution and monthly door-to-door bill collecting.) Spiess has worked in the areas of oil and gas, UAS and precision agriculture, health care, cannabis, agriculture, real estate, government affairs and economic development. Spiess is the host of two radio programs, Building the Bakken and Coffee & Capitalism, and three specialty programs, MonDak OilField Review, Corporate Ink and UnStuck, that carry a radio network that spans five states and two countries. Spiess is a North Dakota native and graduated from North Dakota State University.