Scanning is getting easier in the oilfields. Just ask Texas-based S Oliver and Associates (SOA), which has provided surveying services for the oil and gas industry for more than 20 years. The varied and changing requirements of its clientele call for flexibility, innovation and the ability to implement solutions to handle site-specific challenges. Like most surveying firms, with increasing demand for 3D scanning, SOA welcomed any opportunity to use new technologies to improve efficiency and overall job productivity.

Though SOA’s primary focus is on pipeline surveys, it often receives requests for scanning. Maintaining aboveground pipeline equipment often requires detailed surveying and modeling, work that lends itself to scanning. SOA had tried scanning more than a decade ago but had never invested in a scanner until a client presented a large, complex scanning project and the firm declined. “We felt it was too big a project for our first return to scanning,” SOA project manager Jason Trevino explains.

Instead, the company concentrated on developing a flexible and productive approach to serving its clients. Technology was key, and one early purchase was a Trimble SX10 scanning total station, which enabled them to scan and survey with a single instrument.

Challenging Site Demands a Flexible Approach

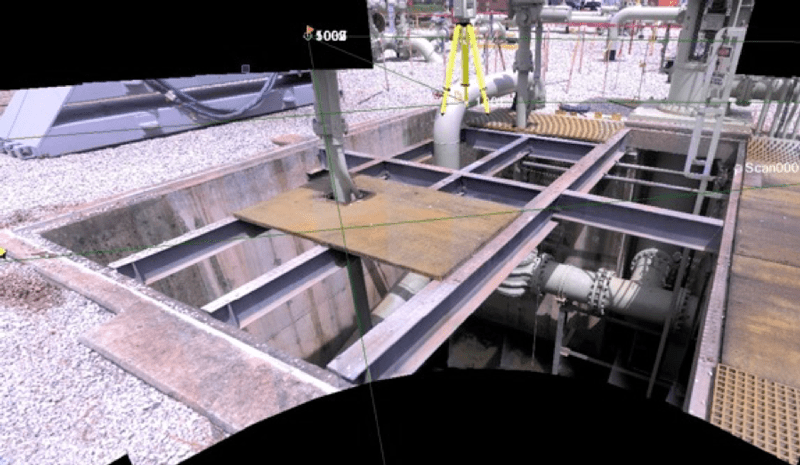

An early job required SOA to provide a detailed survey of a 15-acre (six hectare) tract that contained a large excavation exposing several large pipes. The site also held a roughly 10,000-square foot (900 square mile) area filled with pipes and equipment, including a 900-square foot (80 square mile) in-ground vault containing piping, flanges, tees and valves. To have crews climb into the vault for the survey meant removing grating over the vault, a process that entailed costly and time-consuming procedures for approvals, safety and plant operations.

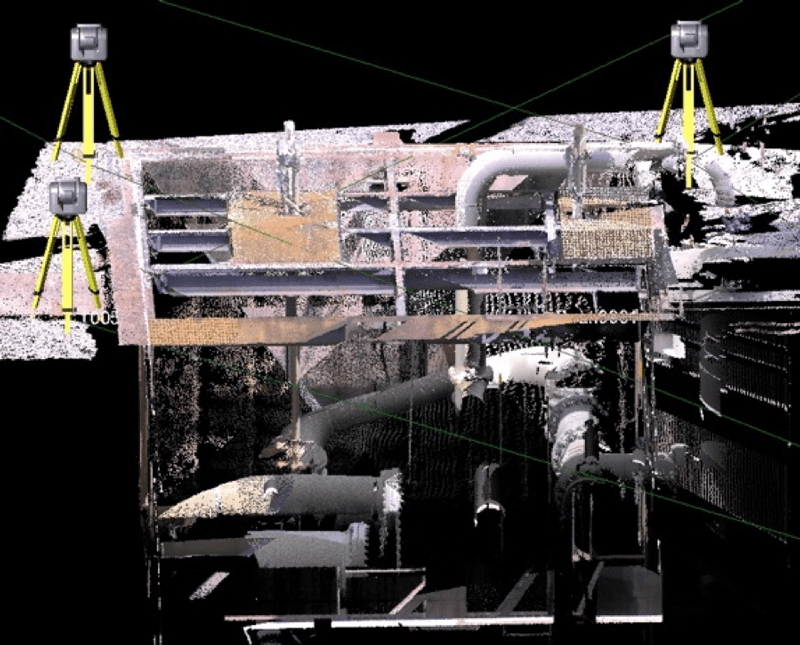

To work around the constraints, SOA crews used the total scanning station to establish control points around the site. Then, for subsequent setups, they used resection to accurately determine the instrument’s location, typically with residuals of 0.02ft (6mm) or less. The approach enabled them to place the SX10 in optimal places for both scanning and conventional total station measurements.

Rather than removing the vault grating, crews could use smaller openings to safely measure the equipment in the vault. By placing the scanning total station in strategic locations, they completed the vault scans with just three setups in half a day. Surveying the remainder of the site required another half day and included scanning as well as prism measurements for precise location of the excavated pipes. The SX10 also captured high-resolution digital images of the area and equipment. In all, the crews visited the site on three separate days to set control and capture comprehensive data.

Integrating Complex Information

SOA technicians used a business software throughout the project. For the control, they combined data from the SX10 as well as digital levels and GNSS receivers. “Most of our GNSS work is done with Trimble VRS,” Trevino says. “And we have long used special software for QA/QC on our data and for computing control coordinates.”

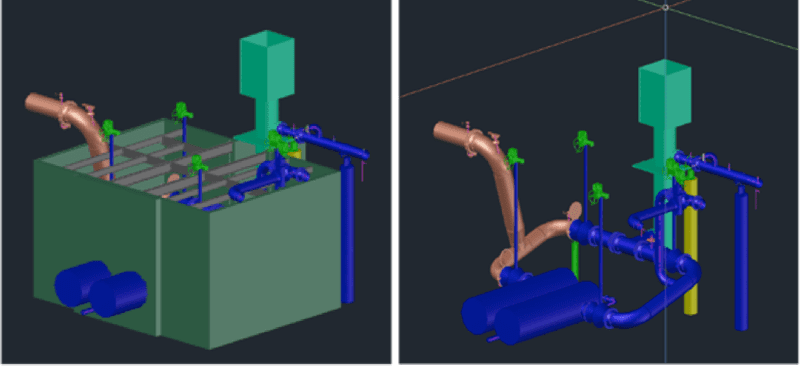

Using the software’s scanning module, SOA technicians quickly combined all the scans from the project site. Because all setups were resected onto project control, no adjustment was needed. The finished point cloud was delivered to engineers in PTX format for use in Autodesk and LFM modeling software.

“SOA and its clients were impressed by the scanning, and welcomed seeing the scanning total station in action,” Trevino says. “We had scan[ned] data from three different days and everything fit together nicely. It was an easy deliverable for our first project.”

Headline photo: An SOA surveyor uses the Trimble SX10 for pipeline locations.

John Stenmark is a writer and consultant working in the geospatial, AEC and associated industries. A professional surveyor, he has more than 25 years of experience in applying advanced technology to surveying and related disciplines.