Detection of methane, hydrogen sulfide, carbon monoxide, hydrocarbons and other gas leaks, is becoming increasingly critical to gas plant safety and emissions monitoring in the heavily-regulated oil and gas industry. Reducing costs, improving safety and complying with regulations require the ability to monitor hard-to-reach areas and many oil and gas producers are augmenting gas detection capability with wireless instruments because eliminating wiring enables lower-cost deployment of more detection points. But those who choose also to do so with standard wireless protocols — such as WirelessHART or ISA 100 — gain the further advantages of plug and play integration, more cost-effective maintenance, and overall operational resilience.

The Benefits of Plug and Play

Plug and play integration makes it easier to integrate gas detectors seamlessly with components and systems from multiple vendors. Proprietary systems lock users into the offerings of one vendor, but by choosing standards-based systems, you have much more flexibility in tailoring coverage to your plant needs. This impacts cost, safety and operations by enabling multiple levels of integration.

At the most basic level, it makes it easier to configure your plant for monitoring of different gases. For example, if you are monitoring for methane or hydrogen sulfide and add a process that requires monitoring for carbon monoxide, standards-based wireless systems make it easier to add multiple sensors that talk to the network and remain vendor agnostic.

Open communication platforms allowing for plug and play integration also make it much easier to integrate gas detection functions with other components of gas detection systems, such as annunciators, alarms, and PDAs (Personal Data Assistances). And beyond that, is easier to integrate gas detection with other safety-critical systems such as flame-detectors or shutdown systems.

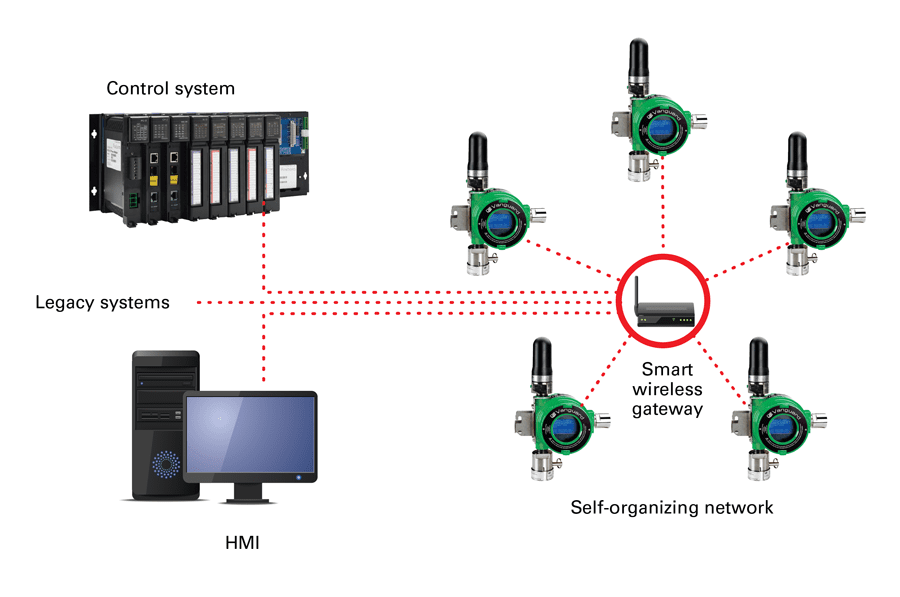

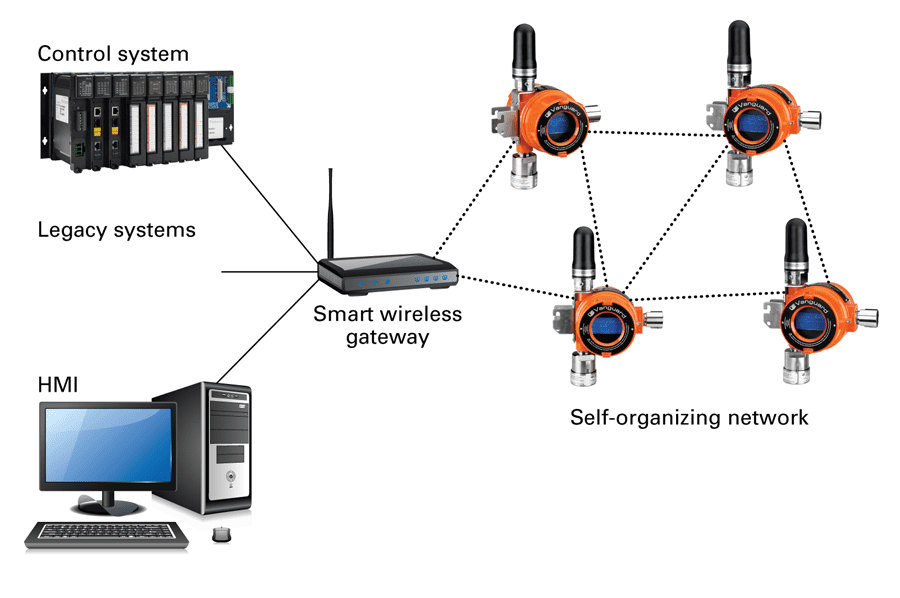

Integration with plantwide information and manufacturing operations management systems such as MES and SCADA systems is also much easier. Support for integration standards enables the collection and analysis of operating and trending data to optimize operations. This also enables integration into the cloud and cross-enterprise. WirelessHART technology, for example, is compatible with all major field and plant network technologies, making it possible to deliver trending and analysis capability across the plant, as well as to digital solutions that integrate cloud technology.

Operational Resilience

In addition to facilitating multiple layers of integration and the benefits that come with that, the ability to mix and match vendor brands improves plant performance by making it easier to implement best-of-breed technology. If you have a standards-based detection system and one of your detectors goes down, you will have more options to replace the component with something that offers more capability than what your current vendor offers.

Not all vendors may have all detection capabilities. So when you have a plug and play system, you may be able to select devices that require less maintenance – perhaps those with longer battery lives – and pair them with compatible devices from another manufacturer that covers different gases. For example, if your primary vendor’s products detect hydrocarbon gases and ammonia but not benzene, but have the wireless features you need and longer battery life, you can stay with your primary system and get the benzene detection from a different vendor. Or if no wireless vendor covers the additional gases you need, you could pay slightly more for a wired version to complete the coverage.

Expandability

Expandability is a benefit all unto itself. When you have maxed out the wiring capacity of your plant and need to expand, wireless is your only option. Using standards makes it easier to find the right combination and implement it with minimal disruption of your current infrastructure.

Reducing Maintenance Costs

Standards-based protocols have significant benefits when it comes to maintenance. Because they share engineering environments in which many more people are trained, you can reap the benefits of open technologies, without having to pay a premium for specialized employees or consultants.

Moreover, manufacturers of field devices are increasingly incorporating standard device management data such as FDI (Field Device Integration), a global standard through which device manufacturers agree to use a common architecture for providing users with device diagnostic and configuration information.

Choosing a Wireless Protocol

The two most widely applied wireless standards are WirelessHART and ISA 100. Both are based on the IEEE 802.15.4-2006 standard and operate on 2.4GHz frequency band. Both are using the same mechanism for data transportation to/from Gateway. And both offer the advantages over proprietary networks we have been discussing so far, but there are many application-specific technical distinctions.

WirelessHART has a self-repairing capability that contributes to network resiliency using a mesh architecture. All WirelessHART devices can function as repeaters in a mesh network. If one node goes down, packets are re-routed to another. ISA100 devices, however, offer this as standard only at the gateway and access point level, not at the device level. This makes for a weaker network that requires more installed components. Either option, however, is superior in this regard to proprietary networks, where the operator must accept only wireless devices from the proprietary device vendor or run separate networks in order to accommodate them.

Another key difference is that WirelessHART can support different transmission intervals by using multiple superframes with different numbers of slots. Each slot has a fixed duration of 10 ms, which is enough time to transmit a packet and receive an acknowledgment message (the maximum packet size is 133 bytes, including headers). ISA100.11a, on the other hand, must be configured between 10 and 14 ms, which means that users will need to ensure that all ISA100.11 devices in a given network support time slot lengths compatible with all other devices in the network.

There are numerous other differences that will depend on what your company may already be running, what kind of reliability your application needs, security requirements, ease of programming vs. customizability and much more.

Joining the Digital Revolution

While wireless gas detection itself offers many advantages in terms of greater density, flexibility and overall simplicity of operation, adherence to standards-based communications protocols adds further advantages. While some proprietary legacy systems remain, the move is toward standards for all of the reasons we have been discussing.

So, if you are now in the process of upgrading your legacy, proprietary gas detection system, give careful consideration to upgrading to standards-based wireless technology. If you are already using a standards-based wireless gas detection, evaluate the instruments available for that protocol, to see if they fill any gaps that you may have in your protection, like long-life batteries, flexible mounting, etc.

If you are not using wireless at all, work with your IT team to conduct a thorough analysis of the wireless standard options that are available based on your needs. Regardless of which approach you take, you can expect to gain significant flexibility, safety and cost advantages as you increasingly participate in the digital transformation that is upon us now.

Chris Frail is the product manager for gas detection at United Electrics Controls in Watertown, MA USA. His focus is on deploying wireless, battery-operated solutions to aid customers with faster, reliable deployment of fixed gas detectors. He graduated as a mechanical engineer in 1997 from Boston University and earned his MBA from Babson College in 2009. Frail has been involved in the management and development of instrumentation for multiple industries for over 20 years. He got his start at Panametrics and GE Baker Hughes, where he worked with customers in the oil & gas and petrochemical industries specifying and developing ultrasonic flowmeters for flare, high temperature and cryogenic fluids and pushing boundaries of ultrasonic meters. His key focus has always been on solving difficult technology problems and making the solution easy to use for the future, as evidenced by his work on portable ultrasonic meters and wetted ultrasonic meters for high temperature applications like coke bottoms in refineries. He can be reached at cfrail@ueonline.com.