The utilization of subsea equipment is essential in offshore oil exploration. Unfortunately, subsea operations aren’t always the most eco-friendly, having the potential to cause negative, long-term environmental impacts and increase carbon emissions. As a result, operators in the oil and gas industry require a solution that makes subsea operations more environmentally friendly and efficient.

Noticing the environmental impact that comes with offshore exploration and a lack of sustainable equipment in the industry, Legasea, a U.K.-based subsea startup, sought to resolve the sustainability issue by providing innovative services to oil and gas operators.

Together, Ray Milne, operations director for Legasea, and his teammates at Legasea decommission and refurbish subsea production and well equipment for various oil and gas businesses, making the parts safe and reusable during production. Now a booming startup with three business award nominations, Milne shared how Legasea was established, the goals and mission Legasea has to improve oil operations, and why innovation and sustainability are critical in the industry.

Legasea was founded based on the idea of “difference” – to create a company that was unlike others, one that placed its values and ethos at the center of the business and gave its personnel real power to drive the company and shape its future. “We planned every element of the organization, and developed a detailed business plan, throughout Q1 2019, moved into our facility in April and then officially launched the business in May,” says Milne. He had met Legasea’s Managing Director, Lewis Sim, back in 2009, ten years prior to the launch of Legasea. “We were both working for a subsea equipment supplier, where we witnessed many instances of good equipment being unnecessarily scrapped,” says Milne.

What prompted Milne and Sim to begin refurbishing subsea production and well equipment was constantly seeing oil and gas operators, over the years, have urgent requirements for equipment that was obsolete. This resulted in expensive, and time consuming, processes to re-manufacture using the original drawings, if available.

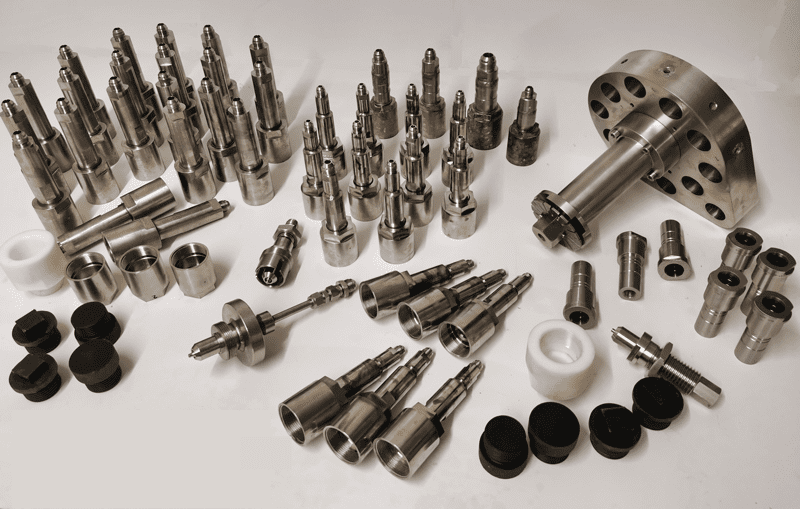

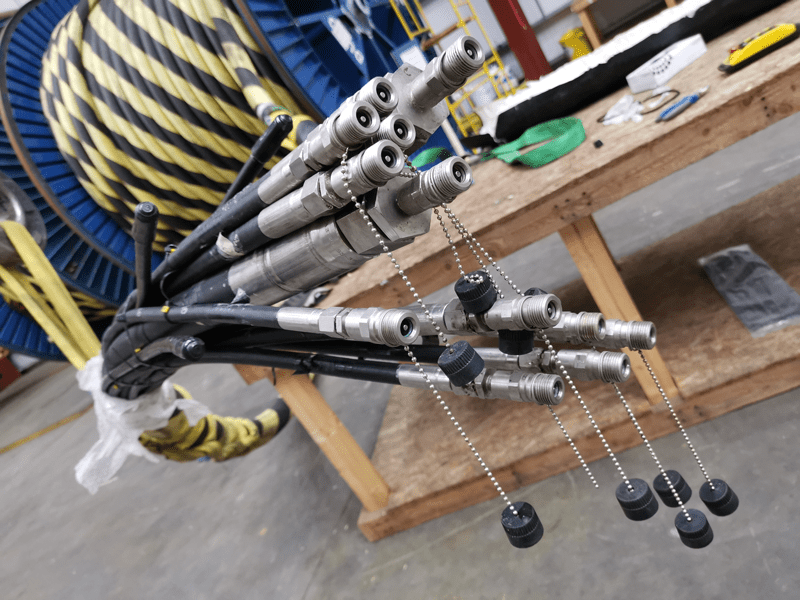

To adequately serve oil and gas operators, Legasea focuses on the “Circular Economy.” “We specialize in production systems and controls, and offer a range of electrical, hydraulic and mechanical engineering services,” states Milne. He further explains how Legasea promotes sustainability and reuse, with its ethos being one of a circular economy, taking one company’s waste and restoring it to be of value elsewhere. “Legasea provides a complete shore-to-store service, for equipment returned following decommissioning, and we also work with surplus inventory that is no longer required by operators,” says Milne.

As a result, Legasea maintains a wide range of clients, including major international oil and gas operators, U.K. North Sea operators, oilfield service providers and renewable energy companies. “The organization works in a range of markets, including subsea oil and gas production, drilling, topsides and renewables,” Milne states.

Although considered a recent company that is still establishing a foothold in the industry, Legasea has received a significant, positive reception, surpassing the team’s expectations. Legasea has managed to establish a diverse clientele of operators and service companies, including several that have placed repeat orders, and worked to add the company to approved vendor lists. “Within the sector, Legasea has been welcomed as a refreshing change to the status quo, and positive feedback has been received from all clients and visitors to our facility,” says Milne.

The services Legasea provides support the positive reception, particularly its restoration process. According to Milne, “The impact is most evident in scenarios, which are becoming more and more frequent, where we get a call regarding an urgent part, and it is ready and available in our inventory. Being able to deliver emergency spares, in a short time frame, has the potential to save our clients millions, when factoring in the cost of lost production.” Milne explains how obsolescence management within the industry, as the years progress, is going to be critical, with various oil and gas producing regions transitioning towards being mature basins. “We are here to mitigate the risks associated with critical parts being unavailable,” he says.

With outdated and underused equipment existing in the industry, decommissioning, refurbishing and risk management services are essential. “There is a significant amount of subsea equipment that is surplus to requirements, that has either been stored as back up equipment, or only used a small number of times. When an oil or gas field is closed, it becomes surplus to requirements and is disposed of,” explains Milne, further explaining that, because much of the equipment is considered obsolete, it is not seen as having any value, since it cannot be sold in its entirety, and simply becomes scrapped. “However, many of the components have value, and there are opportunities to reuse them. Our key objective, with regards to the environment, matches the ethos of the business, as a circular economy business, meaning that we will always do everything in the most environmentally-friendly manner.” Adhering to the ethos of their business, the team at Legasea encountered zero environmental incidents in January 2020, and were since awarded the ISO 14001 certification for Environmental Management.

Actively contributing their own sustainable efforts to the industry, Legasea’s Ray Milne indicates other initiatives he has recently seen occur to make oil and gas operations more sustainable. “There are a number of initiatives ongoing at present, to convert existing offshore wells for carbon capture and storage (CCS).” Milne describes how the CCS projects typically involve three steps, which include: CO2 capture, from a large point source, such as a power station; transport of CO2, by pipeline or ship; and CO2 storage, within underground geological formations. “One example of this is the Acorn project in North-East Scotland led by Pale Blue Dot Energy, which has plans to be operating by 2024,” says Milne.

Even with the recent sustainable initiatives, Milne notes how the mission to be more sustainable in the industry is a difficult one to accomplish. “Sustainability is challenging within our industry due to the use of finite resources that are not renewable.” However, he mentions there are always ways to reduce the impact oil and gas production has on the environment. “By building circular economy principles into the design of equipment, it can be engineered with reuse in mind. Accenture estimates that, worldwide, the circular economy will be worth $4.5 trillion in the next 15 years, referring to it as ‘the biggest revolution in the global economy in 250 years,’ and this represents a great opportunity for the energy sector,” Milne explains.

Applying the principles of circular economy to its products, Legasea offers a diverse line of services refurbished equipment to its customers. “We are very proud to be able to offer a wide range of services all under one roof within our facility near Aberdeen. As there are multiple cranes onsite, we can handle assemblies of up to 75 tonnes, which provides the capabilities to carry out major test and assembly projects, as well as final acceptance tests (FAT) and systems integration testing (SIT),” says Milne. “During these projects, we conduct electrical, mechanical and hydraulic scopes, and we have the added advantage of being able to provide equipment from our inventory of re-certified equipment.”

As aforementioned, Legasea has been nominated for three business awards, due to its innovative and eco-conscious solutions. “All of the nominations have been incredible, and we are honored to have received all of them,” Milne acknowledges. The well-received startup has managed to achieve the nominations in such a short time frame. “Receiving such accolades really helps to validate the considerable efforts of everyone in our team, after a little over one year in business, and they recognize the impact that we have managed to make on the industry along the way,” says Milne.

Following its business award nominations, Legasea plans to continue supporting the oil and gas industry globally and providing innovative and sustainable solutions for its clients. “Throughout 2021, it is our intention to continue to expand our team at our base in Scotland, whilst reviewing options for a variety of locations globally, specifically in key oil and gas hubs, because we work with products which have a global market,” states Milne.

In addition to improving sustainability in the industry, Legasea is focused on making products more efficient, reliable and up-to-date. “Wherever you go, subsea components are of a standard design, and there are limited manufacturers. The global industry is suffering from the same issues, with regards to availability and obsolescence. In the North Sea, we use the same components as a field in the Gulf of Mexico, which uses the same components as a field offshore Perth, Australia,” Milne explains. Ultimately, Legasea is focused on making parts and equipment readily available and usable for operators around the globe, reducing obsolescence in the industry, and minimizing the environmental impacts along the way.

Headline photo: Legasea Facility – Photos courtesy of Legasea

Tonae’ Hamilton has been a contributor and associate editor to the magazine for two years. She has been writing professionally for almost four years. In her free time, Tonae’ likes to spend time with her three pets, cook, and binge-watch Netflix shows. Tonae' has a Bachelor of Arts in Communication from McDaniel College.