In today’s energy landscape, with the shocks in the oil supply and demand, uncertainty looms over the crude oil prices. With advent of more cleaner energy sources and carbon tax from governments, the pricing pressure on the lift cost remains high. More and more companies are cautiously making CAPEX investments in exploration and development activities and are looking to optimize the cost per barrel produced. Even hydrocarbon exploration and production have become increasingly more complex – tighter formations, deep reservoirs, heterogenous lithologies, and extensive horizontal wells – companies face heightened technical and economic challenges.

In this environment, logging while drilling (LWD) technologies have become significantly important as they allow a geosteering decision to place the well in the sweet spot improving producibility, enable faster decision making through real time data transmission, and improve overall efficiency reducing the cost of the well.

The continuous innovation in the new generation LWD technologies, particularly in the domains related to nuclear magnetic resonance (NMR), geosteering and reservoir mapping technologies, and reservoir sampling and pressure, has fundamentally reshaped how sub-surface data is acquired, evaluated, and applied. E&P companies around the globe have evolved their workflows to adopt utilizing these measurements rather than traditional wireline (WL) and create value for them. These developments are not incremental improvements; instead, they have redefined the operator value chain from exploration to production.

The Evolution of LWD from data acquisition to Real Time Decision making

Traditionally, wireline has been the main source of data acquisition in the oil and gas industry. However, as the drilling of wells became more complex with more long reach horizontal wells, 3D trajectories, deepwater wells, high pressure high temperature (HPHT) wells, etc., the limitation of WL conveyance became evident and acquisition via LWD became the new norm.

What started with packaging of basic gamma ray and resistivity sensors into a drill collar, LWD technologies have evolved into much more complex measurements. The focus has shifted from gathering data for post drilling evaluation to real time decision making for better well productivity. This shift has been a true value creation for the E&P companies.

LWD High-Definition NMR While Drilling: From Pore to Production

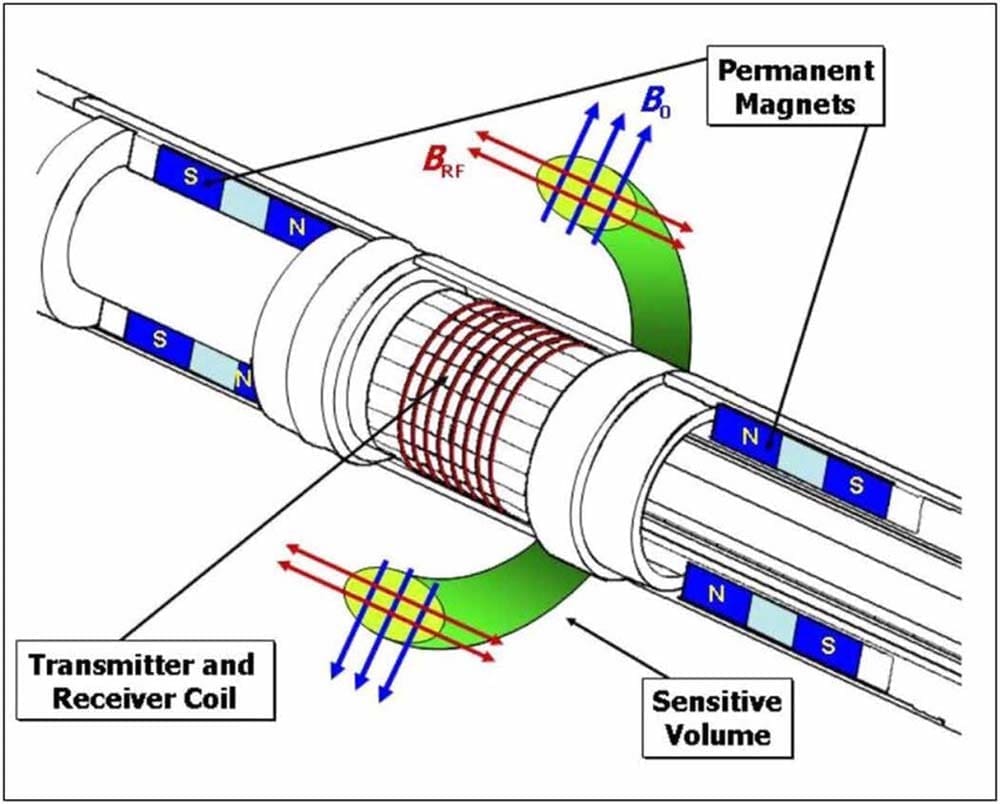

Nuclear magnetic resonance or NMR measurements is one of the most advanced formation evaluation technologies and are today utilized in many applications. Traditionally, NMR measurements have been used mainly for petrophysical evaluations, such as lithology independent porosity, permeability, bound fluid volume, and free fluid volume. Differentiating between movable and bound fluids, identification of light hydrocarbons versus water, and estimation of permeability allows companies to make better reserve estimates of exploration and appraisal wells. NMR application has also expanded to rock quality identification and geosteering wells depending on the porosity-permeability profile of the rock type being drilled. NMR measurement is also used to optimize the formation testing program by picking up the pressure and the sampling points. Finally, NMR measurements are used to determine grain size distribution that aids in completion optimization.

Getting good reliable NMR measurements consistently from LWD was a challenge. LWD NMR data suffered from a restricted rate of penetration (ROP) and the measurement’s quality was impacted from the drilling noise and the drilling BHA lateral motion. With modernized electronics, advancement in the digital modeling capabilities, and a ruggedized magnetic sensor assembly, LWD NMR measurements are able to provide WL-like data quality.

Geosteering: No Place for Oil to Hide

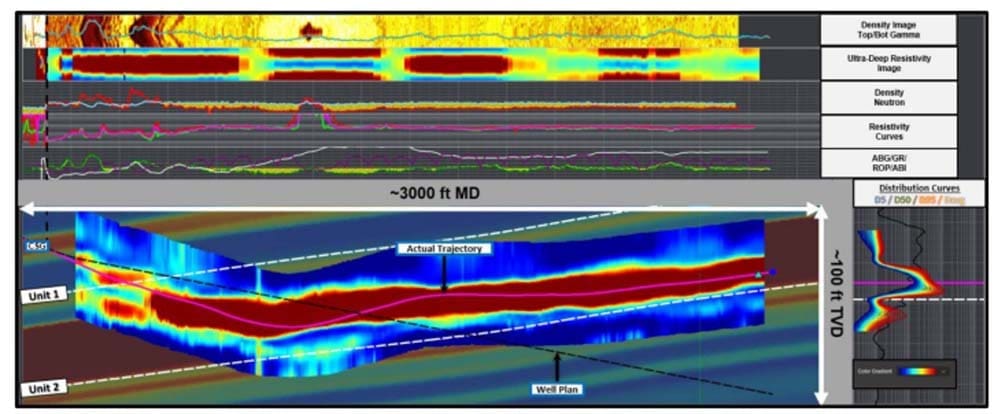

There is no other LWD technology that incorporates the synergy between tool measurement and operator action as effectively as geosteering. Legacy geosteering techniques embodied utilization of basic gamma ray, resistivity, density and imaging services with correlation from offset wells to place the well in a sweet spot. However, modern geosteering solutions utilize deep directional measurements, together with sophisticated modeling and visualization, to guide the bit along the optimal trajectory inside the reservoir.

Advances in the geosteering technology have now enabled companies to see the formation tens of feet ahead of the bit and allowed for proactive geosteering rather than reactive decision making. Accurate geosteering maximizes the reservoir contact, prevents unwarranted and costly sidetracks, allows for casing point detection, and avoids entering faults and shale zones. The adoption of geosteering technologies among the E&P companies has seen a significant side over the last decade, leading to higher production rates, improved well recovery, and reduced number of wells per field.

Formation Sampling While Drilling: The Fluid Story

Formation sampling while drilling (FSWD) technology helps capture fluid samples and measure its properties downhole in-situ conditions while drilling. The development of FSWD technologies represents one of the most sophisticated achievements in the LWD world because of its inherent complexity.

Typical FSWD technologies consist of multiple toolsets that are mechanically complex, require high power, and have to work in synchronization to provide a seamless service.

FSWD technologies provides formation pressure and mobility measurements determining the formation gradient and collect multiple fluid samples while allowing for fluid type identification, different fluid properties such as GOR, composition, etc., and the formation fluid contamination estimation. Development of FSWD has brought clear benefits to the companies such as reduced operational time by eliminating WL runs, improved reservoir understanding and de-risking of field development plans. The integration of formation fluid sampling together with other formation rock properties completed the loop of real-time formation evaluation via LWD.

The value drivers for LWD measurements have been the tangible benefits it creates for the E&P companies in multiple dimensions, such as technical certainty by providing high quality formation evaluation data, operational efficiency by eliminating multiple WL runs and the economic impact by real time decision making.

The Road Ahead: Integrating LWD measurements with Digital and Automation

The innovation in the LWD technologies have transformed the drilling activity from a pure mechanical operation to a reservoir optimized process. The future of LWD lies in integration of downhole LWD formation evaluation measurements with digital, automation and machine learning. With all the companies investing in automated interpretation and AI assisted geosteering, the value of LWD measurements will be further enhanced. As the oil and gas industry continues to evolve, the companies investing in new generation LWD technologies, digital solutions and automation will not just drill wells, they will engineer insight, efficiency, and value – one foot of a hole at a time.

Vivek Agarwal is the Product Champion at one of the world’s largest oilfield services companies, bringing over 17 years of diverse experience in the energy industry. He holds an MBA degree from Rice University, Texas, USA and an engineering degree from Indian Institute of Technology Kharagpur, India, and began his career as a field engineer working both offshore and onshore fields.

Throughout his career, Vivek has taken on multiple roles spanning operations, engineering, sales, marketing, and product management. His extensive experience across Asia, North America, and South America has allowed him to collaborate with leading energy companies, driving innovation and delivering impactful solutions. With a strong blend of technical and commercial acumen, Vivek continues to play a key role in shaping technology portfolio and supporting global energy initiatives.