There is a missing piece in the oil and gas industry, a hole, if you will. We’ve all, as a collective group, come to an impasse in this industry. We knew it was coming, but as it sneaks up on us, in whatever group we belong, we are affected by it in some way. The missing piece is knowledge. Knowledge that is lost in the abyss called the skills gap. On the job, hands-on skills and more importantly, experience. People are the tool that make this industry turn. People furiously working in offices across the country and world, to produce things on paper that will turn into a successful, thriving product. In turn, it’s the other half furiously working to literally and physically bring to life what is on that paper and make it happen. In oil and gas, it’s the team of people on both sides that makes the outcome prosperous. What happens when the knowledge, the critical piece to this puzzle, threatens to break apart this perfectly orchestrated team?

The slowly forming hole in this puzzle is the wealth of knowledge that the baby boomers possess that they will be taking with them when they retire. Some of them have already made the transition and the rest are inevitably on their heels. The Millennials have the degrees and the jobs, but not the experience. The other component to this hole is the fact that the baby boomers that are still working and Generation X behind them, are somewhat reluctant to adapt to the new software and IoT (Internet of Things) that is becoming the norm in the workplace. These are all generalizations, of course, but in talking to upper management in various companies across the industry, this concern seems to be a trend that is becoming more commonplace.

Bridging the Gap

EKT Interactive

The situation may seem dire, but there is a way to bridge the gap. Training and continuing education are crucial to an ever evolving oil market. From classes you can physically attend to learning essentially on demand, there are countless options.

Companies like EKT Interactive are crossing the intersection where oil and gas meet e-learning. When asked, Marty Stetzer, EKT President, how he got his start, he said, “I had 30 years in the upstream and downstream, always a part of the startup or turnaround where training was important. In the down turn of 2014, I realized that I had 30 years of training materials and could reach those who needed this information.” This concept allows industry workers to learn around the way they live and in their own time with audio, video, e-books or podcasts. EKT stands for Energy Knowledge Transfer. Ironically, exactly what we’re visiting here now. When EKT got their start, their goal was to make e-learning three things: interesting, memorable and relevant. It also needed to meet objectives, the main one being knowledge. One of the obstacles EKT faces, which differs from other training courses, is that if someone is not interested, they can click out, as opposed to a classroom where they’d be much more reluctant to leave. “Because of this, EKT is constantly striving to engage their students and eliminate the SOP (Same old Powerpoint),” says Stetzer. For instance, one of their packages “Oil 201” is a deep dive into the knowledge portion of the industry. It is laid out in e-book format in 10-15 minute increments with a concept they call “micro learning.”

There are many people out there that work in the oil and gas industry, but are not necessarily a direct instrument that produces the final product. They are the oil and gas support, while not directly involved, still have the desire and need to be educated about the industry in which they work. So while it may not be required for them to necessarily get a certification, they can still be informed. EKT has many packages to fit the individual client, whether the focus is awareness or knowledge. To start, they even have a “three for free” package that is an introduction to the upstream, downstream and midstream.

It’s exciting to think of oil and gas education becoming so progressive. There are many companies dedicated to this cause and because of that, some of their methods differ, but the end goal remains the same.

Technical Toolboxes

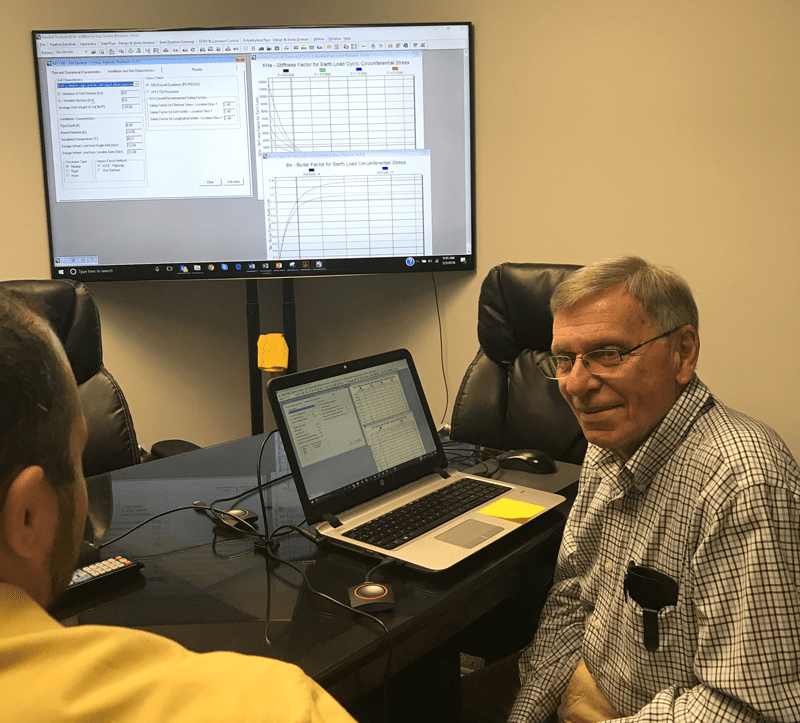

Technical Toolboxes is a company that specializes in software and on-the-job training, primarily covering the midstream. When asked about their training classes, Paul Schumann, Technical Toolboxes’ Training Product Line Manager stated, “We offer in excess of 20 unique specialized classes that cover all phases of the pipeline lifecycle from design, construction, and operations through integrity. RSTRENG is our most popular class in terms of classes held per year and it specifically addresses key areas in the integrity phase of the pipeline lifecycle.”

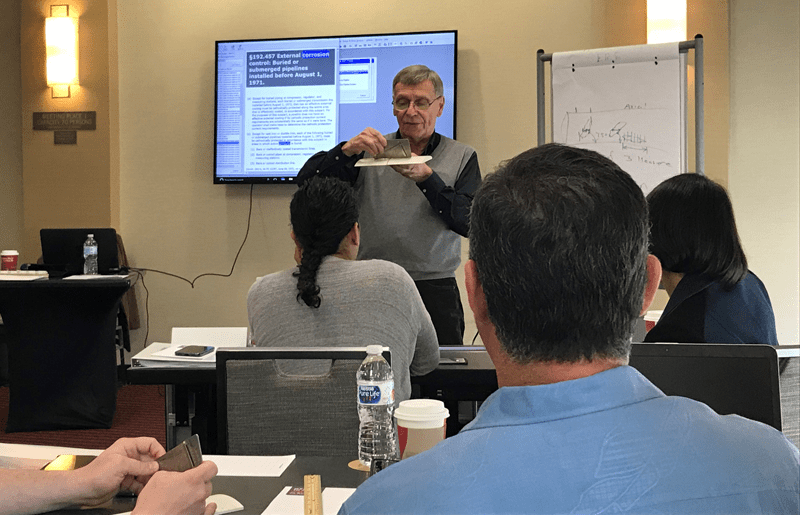

I sat in on one of these training classes to get a feel for how they are conducted and who constitutes their primary audience. The class was “RSTRENG & Defect Assessment,” given in Houston. RSTRENG is a Technical Toolboxes copyrighted software that they offer and it is called by name in 192 and 195 Code of Federal Regulations. When asked what “RSTRENG” stands for, Schumann stated, “RSTRENG is indeed an acronym for ‘Remaining Strength.’ It is based on research from PRCI (Pipeline and Research Council International) in order for pipeline operators to effectively assess the safe operating pressures in aging pipelines due to metal loss damage (corrosion) and remaining life. The class is more centered on RESTRENG+ which includes additional analysis that Technical Toolboxes includes in software packages.”

Technical Toolboxes’ training and instructors are highly specialized. A gentleman by the name of Joe Pikas instructed the RSTRENG class. Mr. Pikas has more than 50 years’ experience in cathodic protection, above and underground coatings and corrosion control design and implementation which includes project engineering management. He is an expert in pipeline integrity management, risk management, coating materials selection, cathodic protection design and testing, and pipeline internal and external corrosion control. He has been the recipient of several awards and has contributed many papers for industry trade magazines, NACE and SSPC publications and conferences. To say that he is an expert in this field, is a vast understatement. “Joe Pikas brings a unique background that has provided him the opportunity to participate in the research of RSTRENG, among other products, and has subsequently had the opportunity to apply these learnings in the field. As a result of his highly specialized training and practical experiences, he is able to add training value to the novice through the experienced pipeline engineers and technicians,” says Martin Fingerhut, Technical Toolboxes’ Chief Executive Officer.

Technical Toolboxes takes their task of educating the industry very seriously. “Historically, there was a focus on associating the Technical Toolboxes’ brand with high quality non-sales oriented technical training. Today, we continue with the same level of high quality technical training, largely related to theory and background knowledge required to operate a growing inventory of specialized software products properly,” says Drew Lafleur, Technical Toolboxes’ Chief Operating Officer. The RSTRENG training was over a span of a day and a half. It was for the certification, training and testing of individuals seeking technical certification for corrosion assessment. In addition, dents, gouges, weld anomalies and related pipe and vessel defects were covered for assessment and analysis. It also covered the following: understanding and recognizing pipe defects, flaw detection, measurement corrosion features/defects, analysis of corrosion features and feature identification, and data features for post processing and reporting. After the course, students had to pass a written examination and a practical examination, where two types of defects were to be analyzed. Upon successful completion, students received a trial of RSTRENG software, course notes on paper and in a flash drive and a certificate of completion awarding 12 PDHs.

The atmosphere of the class was extremely informative and engaging. When I walked in to observe, what I witnessed was the exact solution that we are exploring here. A man with an incredible wealth of subject matter knowledge collected over many years, is passing that along to mostly people between the ages of 30-40 years old. The students were captivated and full of questions. Questions that Mr. Pikas did not hesitate for a second to answer. “We recognize a generation gap exists in the workforce and that knowledge is leaving organizations as the experienced engineers and technicians are retiring. Our direction in the training space is to better engage millennials and encourage further knowledge transfer within industry and organizations,” says Lafleur. Technical Toolboxes is doing their part to educate the industry, they have done so for many years and they are not stopping any time soon. Fingerhut stated, “Technical Toolboxes specializes in midstream pipeline solutions in both the software and training spaces. After 20 years of supporting the pipeline industry, Technical Toolboxes continues to advance from calculation to simulation type products for pipeline operators and engineers alike, and recognizes that advancements in software require training methods to address a diverse workforce.”

NExT – A Schlumberger Company

NExT is another training and education organization doing their part in the industry to bridge the skills gap. Eighteen years ago, Schlumberger and three universities that offer petroleum studies programs, Texas A&M, University of Oklahoma and Heriot-Watt University, created a program called NExT (Network for Excellence in Training). Schlumberger acquired the commercial rights of NExT and retained the program’s original instructors, however, they added petrochemical experts and industry-recognized consultants to the NExT staff. Today, NExT has more than 3,000 expert instructors who train more than 15,000 technical professionals each year in 11 core disciplines – from characterization and exploration through development and production – and in industry-spanning domains.

NExT offers a full suite of training courses in upstream oil and gas industry disciplines as well as surface facility and midstream training for operators and technicians. Their training programs consist of classroom, workshop and field exposure and on-the-job mentoring. The training they offer is not exclusive to Schlumberger employees, the classes they offer are both private and open to the public. NExT designs their training programs using a blended learning approach that encompasses the following:

- Mentoring

- Operations Assignment

- Expert-led Training

- Self-Learning

- Research and Technology Center Tours

- On-the-job Projects

- Field Course

- Software Tools and Workflows

“In essence, NExT is the largest Petro Technical Training and Competency Development provider in the world, helping organizations, teams and professionals build their technical skills for the E&P challenges that they face,” Peadar McKkvitt, NExT Schlumberger Global Resource Manager, stated. “We are now grafting onto our industry key Digital Technology capabilities so that E&P PetroTechnical experts can optimize the discovery, development and management of their assets. Connecting people and technology (PetroTechnical and Digital) we are building a Digital Learning Ecosystem for the future. Working with our clients and extended resource network, we are now actively creating that future together!”

NExT has access to well-equipped, global Schlumberger training centers and technical facilities, where participants gain practical, hands-on experience. The training centers are located in the following places: Tulsa, OK – Rio de Janeiro, Brazil – Melun, France – Abu Dhabi, UAE – Tyumen, Russia. This also goes hand-in-hand with the geology field trips that they offer, which are also global. The whole concept of being able to learn in such a hands-on environment is exciting and engaging. Geology can be better studied in the field and learning by doing puts things into their proper scale, context, and perspective. With a carefully selected portfolio of practical, high-quality field trips covering relevant depositional and tectonic environments, NExT meets the needs of working geologists and petroleum engineers and the companies that rely on them to meet their goals.

The field trips build expertise and develop practical interpretation skills by improving the understanding of geological complexities, strengthening technical knowledge through exposure to new and diverse geological environments, delivering broader perspectives and new insights through hands-on field experiences. The experiences include trips to road cuts, ancient outcrops, modern sedimentary environments, core analysis laboratories, and research facilities. The field trips broaden understanding with first-hand experiences in field formation evaluation, log and core analysis, and 3D reservoir modeling. Course topics include the following: faults and fractures, carbonate platforms and reefs, shallow carbonates and evaporates, fluvial-deltaic and deep-marine clastics, rift zones, turbidites, and deltaic fan systems. They truly cover all the bases and provide invaluable knowledge to their students.

Optimistic Outlook

There is no doubt that the skills gap is a real, valid issue in the oil and gas industry. However, there is hope – not all will be lost with the retirement of the baby boomers. Because of companies such as EKT, Technical Toolboxes and NExT, there are options out there to educate the workforce. Not only educate, but truly inspire and pass down this extremely valuable knowledge in the most innovative and engaging way possible. These companies and many like them are not stopping here. They are going further out of the box to keep the wheels turning. Knowledge is power and when you have power to offer, it’s a good business to be in.

Sarah Skinner is a graduate of Louisiana State University with a degree in English. She has been a technical writer and editor in the oil and gas industry for over ten years in Houston and in Louisiana. She currently works as a technical writer for a pre-cast concrete construction company in Louisiana that builds blast-proof buildings for petrochemical plants.