The world’s energy demand is steadily increasing to the point that it has now become difficult for conventional hydrocarbon reservoirs to meet demand levels. Therefore, oil and gas companies have gone through rapid changes to adapt, survive, improve processes, create automation, generate value and are also seeking novel ways to exploit and unlock the potential of unconventional resources. These resources have been known to exist for some time and their production has become increasingly economically viable over the past decades through the industry’s continuous technological progress based upon the combination of horizontal drilling and hydraulic fracturing. Drilling of high-pressure, high-temperature (HPHT) wells and shale reservoirs has become more widespread in the global petroleum and natural gas industry. There is a current need to extend robust techniques beyond costly drilling and completion work, with the potential for exponential expansion. This article identifies some operational aspects that must be taken into consideration when operating unconventional reservoirs.

Unconventional Reservoirs

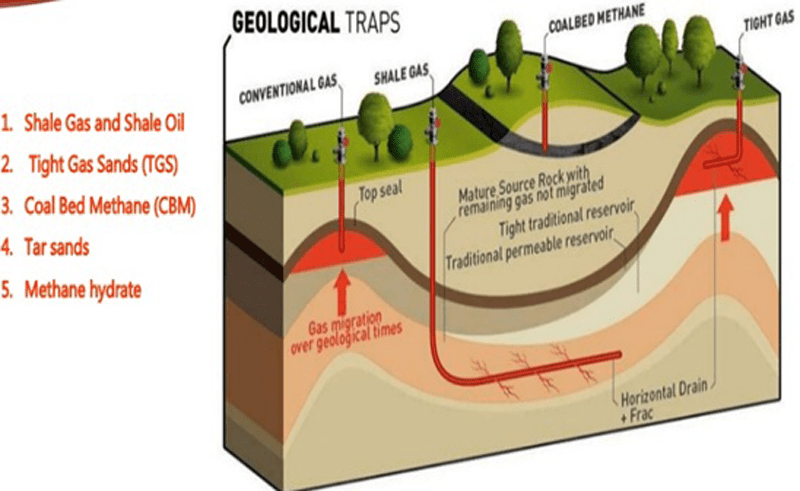

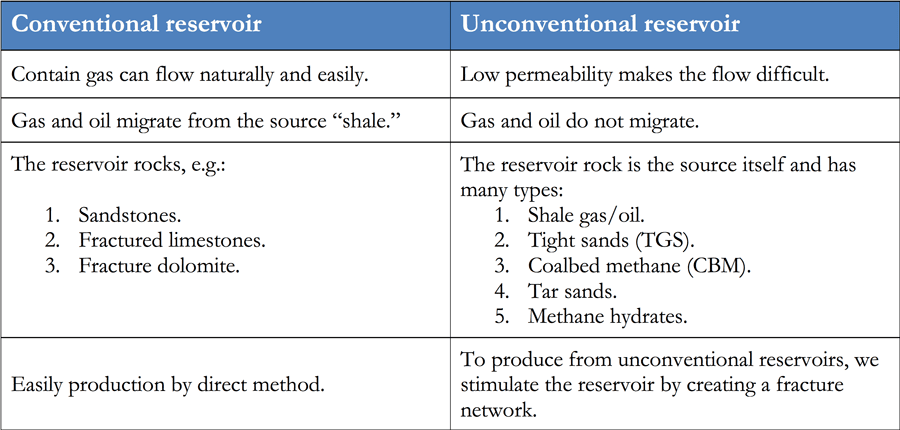

When we talk about unconventional reservoirs, we essentially refer to any reservoir that requires special recovery operations outside the conventional operating practices. Unconventional reservoirs include reservoirs such as tight-gas sands, gas and oil shales, coalbed methane, heavy oil and tar sands, gas-hydrate reservoirs, and high-pressure, high-temperature (HPHT) wells. These reservoirs require assertive recovery solutions such as stimulation treatments or steam injection, innovative solutions that must overcome economic constraints in order to make recovery from these reservoirs monetarily viable (1).

Unconventional Versus Conventional Reservoirs

The oil and gas industry has used the terms “conventional” and “unconventional” resources for decades, although no standard definitions exist. At its most basic level, a “conventional” resource will flow on its own to the wellbore, while an “unconventional” resource will not. Unconventional resources require the application of external stimulation to enable hydrocarbons to flow. Hydraulic fracturing, which cracks underground source rock releasing gas or oil embedded within it, is one such form of external stimulation.

The terms “unconventional” and “conventional” can cause confusion in the public. They can imply that conventional means simple and unconventional means difficult. The distinguishing feature is whether the oil or natural gas can naturally flow on its own, not the relative ease or difficulty in extracting the resource. The term “unconventional” neither refers to nor requires operational difficulty, just as “conventional” is not defined by operational simplicity. In fact, the unconventional resources can be developed by less complex means than the operations involved with many projects that are accessing and producing conventional resources (2).

Operating Unconventional Reservoirs

The economic viability of developing unconventional resources depends upon many factors. These include:

- Geology (nature of resource, nature of source rock, resource depth, size of resource, etc.).

- Geography (size of markets, proximity of resource to markets).

- Topography (ability to construct well pads, water sources, sand sources, etc.).

- Governance (nature and stability of laws and regulations, over-arching fiscal regime, mineral ownership, lease/resource access, royalties/taxes, liability exposure, right-of-way policies).

- Supporting infrastructure (roads, railways, waterways, power sources, pipelines, disposal options, worker housing/social services).

- Supporting labor force (availability of trained personnel).

- Materials and equipment availability (drilling, fracturing and environmental management equipment, cement, gravel, sand, chemical additives, trucks, piping, etc.).

- Pricing (the price being offered for the given oil or gas commodity at the time of investment decisions).

The costs and anticipated development pace associated with each of these factors can encourage or discourage investments in one location relative to other regions or countries. In the United States, supporting infrastructure, labor and supplies, as well as other factors have contributed in many instances to a favorable climate for unconventional resource development investment and expansion. To develop an unconventional resource, several steps are undertaken to drill a well and begin producing it. Generally, the time to construct a well is relatively short (months) compared to the time the well viably produces a resource for sale (decades).

When developing an unconventional reservoir, non-conventional processes must be put in place, there are some few tips we could considerate for this, each one for each discipline (2).

Drilling

When drilling a well in unconventional reservoirs many factors must be considered in order to secure its integrity, which is achieved by a properly designed and constructed oil and gas wellbore based on right well drilling trajectory, drilling fluid design, features on casing to use, cementing.

Drilling trajectory. Most of the wells drilled on unconventional reservoirs are horizontal, which is why determining the optimum drilling trajectory is such an important point, achieving this involves the analysis of different elements, such as azimuth, well inclination, sand thickness, layer dip, reservoir’s structure, pore pressure, magnitudes of vertical and horizontal stress, collapse and fracture pressure. The best hole stability is obtained by drilling in the direction of the least deviatoric stress; that is, in the direction where the perpendicular stresses present the smallest difference.

Drilling fluid design. The HPHT environment requires suitable techniques and selection of particular technologies in order to conduct drilling into extreme environments. Drilling engineers currently require thermally stable, multifunctional, environmental and inexpensive durable drilling fluid additives for the drilling of unconventional HPHT reservoirs. Below there are several tips to ponder when selecting a drilling fluid system for the HPHT environment, which include:

- Narrow drilling operating window versus high density of HPHT drilling fluid.

- High-density drilling fluids may plug nano-pores in unconventional reservoirs in particular shale.

- Thermal stability of fluid products and systems.

- The technical performance of the fluid for the HPHT environment should be placed as the main priority, not cost, as the margin for error in the HPHT environment is very small, causing the whole operation to fail with the underperformance of drilling fluid.

- The fluid and additives should be stable at high temperatures and withstand the maximum expected time under the most extreme conditions.

- For HPHT operations, well and drilling fluid programs become more critical, where it is important to prepare backup plans (3).

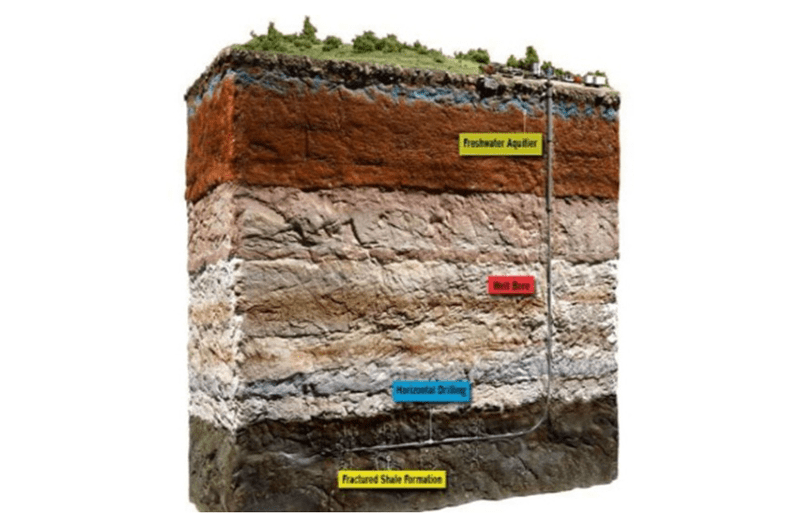

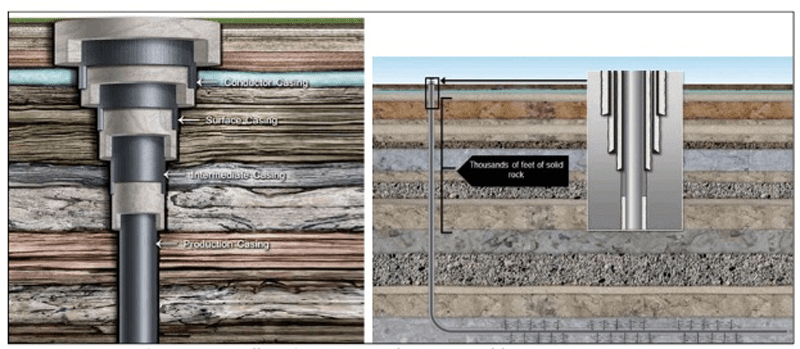

Casing and cementing. As oil and gas companies must carry out different stimulation methods for the development of unconventional reservoirs, there are many pressing questions concerning the development of these resources, such as, “Will my drinking water be safe?” Here is where casing and cementing selection plans take an important role. There are protective measures that consist of multiple layers of steel casing and cement to separate the well from the aquifer and also to isolate production streams within the center of the well. Casing and cementing designs must be based on real data obtained from previous wells. Testing the casing and cement is necessary to ensure they do not create a pathway for oil and gas to enter the water table. In addition, hydraulic fracturing completions are closely monitored and managed to ensure that the pressures involved do not exceed well design parameters (1).

Starting-up and Developing an Unconventional Reservoir

The development of drilling horizontal wells and using multi-stage hydraulic fracturing have made the exploitation of unconventional reservoirs not only possible but also profitable reserves for small and big operators. These new extraction methods have led to the shale reservoirs playing a major role in the oil and gas industry, and these reserves are providing clean energy, environmental sustainability and increased security. The U.S. Energy Information Administration (EIA) predicted that shale gas production would increase by 23 percent in 2010 and 49 percent by 2035.

It is important to examine the different natural fracture systems present in coalbed methane and shale gas reservoirs, the connection between hydraulic fractures (created during frac work) with natural fractures in the reservoir creating the necessary channels for optimum production. Therefore, a moderate presence of natural fractures is necessary to economically produce from shale reservoirs. A coalbed methane reservoir has a uniform fracture network making it easy to model while the shale matrixes possess a non-uniform fracture system that requires sophisticated models, such as quad-porosity and double-permeability models.

In addition to the amount and quality of shale organic content, water saturation must also be under 45 percent for production to be economically feasible.

The clay content of shale is another important parameter to investigate for shale reservoir evaluation. Clays are soft and loose materials formed as a result of weathering and erosion over time. Some clay swells when in direct contact with water and this can cause a reduction in the efficiency of hydraulic fracturing. Moderate clay content (under 40 percent) is needed for a marketable production in shale reservoirs.

Rock mechanical properties, such as brittleness, Young’s modulus and Poisson’s ratio also play an important role when designing a fracturing process. A high Young’s modulus and low Poisson’s ratio are the goal in hydraulically fracturing a zone. Rock brittleness is often used as an indication of formation fracability.

Reservoir pressure, also known as pore pressure, is another important parameter in commercial production from shale gas reservoirs. Reservoir pressure needs to be above normal, which is defined as any reservoir with a pressure gradient >0,465 psi/ft. Areas that have above normal reservoir pressure gradients are considered optimal for production enhancements. By using RFTs and MDTs, reservoir pressure can be estimated (4).

Internal Risks

The safe and efficient development of unconventional resources depends on two important elements. A company should have both a responsible operation philosophy and an established and effective risk management approach or framework. All businesses have risks and it is important to identify these risks, make assessments based on real data, and put in place mitigation measures to reduce the risks to an acceptable level for both the operator and the community where it is operating. Risks should be assessed by their probability and consequence, using operational expertise complemented by technical studies that enable companies to mitigate and manage risks based upon real data from actual developments (2).

Conclusion

Unconventional reservoirs are resources that to be economically exploitable must be accompanied by a strong multi-disciplinary management that guarantees adequate design and control of its operations, based on technical knowledge and experience acquired in practice, since it depends upon many factors. A good understanding of the difficulties involved in carrying out successful operations in this type of reservoir is necessary.

One of the most relevant disciplines for the development of unconventional reservoirs is geomechanics, since it generates results that range from the generation of an optimal operational window (mud density when drilling) to the optimized design of the hydraulic fracturing for the commissioning of the wells.

References:

Headline photo: Unconventional reservoirs. Source: Popular Mechanics

Jose Osoriohasworkedas a petroleum engineer forthreeyears.He hasworked for the oil andgas industry as an industrial electromechanical technician for Turbinas y Mecanicas, c.a.andas an oil reservoir development engineer forPetroleos de Venezuela, s.a.Osorio hasexperience on AutoCad industrial designs,gas artificial lifting method Simulators Software. He isable to give supporttoany content related to the oil and gas industry, and analyze well designs, develop geomechanical models for conventional reservoirs, handle and give support with software related to the oil and gas industry, plan well intervention activities to obtain required well/reservoir performance data, perform production optimization activities to ensure reliability and optimum well performance,andchampion new technologies aimed at improving well productivity. Osorio hasknowledge of various oil and gas software/data-viewer (WellFlo, Ofm, Pipesim, Drillwork, Sisub, Centinela, COPyR, Skua-Gocad, MS Office), developing special techniques, procedures, tests and evaluatingnew technologies to enhance production and safety of wells,andtranslatingtechnical documents related to the energy industry.