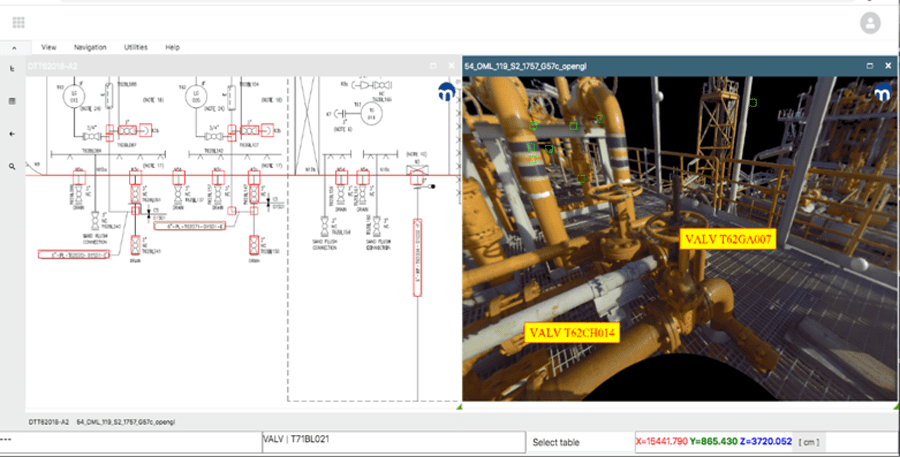

A 3D Digital Twin is a virtual replica of assets, consisting of “point cloud” data captured by Light Detection and Ranging (LIDAR) scanners, which is used to update Piping and Instrumentation Diagrams (P&IDs). This data is connected to a plot plan and users can navigate between the three (plot plan, point cloud and P&IDs) to perform a virtual walkthrough of a facility, where the data mentioned above has been curated and made accessible in the Cloud via a web browser. A 3D Digital Twin can be useful for buyers, sellers and due diligence service providers of industrial, above-ground assets with some degree of mechanical complexity in the oil and gas, process, mining and manufacturing industries.

The benefits of a 3D Digital Twin include:

- Overcomes issue of outdated engineering drawings pushed to the VDR, spurning questions regarding as-built status.

- Provides users with richly detailed asset virtual reality and browser-based access to perform a virtual asset walkthrough.

- Reduces Q&A about as-built status of the assets since P&IDs are updated and accurate, reducing time to complete due diligence.

- A viable and timely alternative to physical inspection of assets.

- Provides seller with a marketing tool to showcase the assets with guarantees of accuracy and reduced buyer remorse.

- Supports due diligence professionals (including SMEs, valuation, and Representation and Warranty policy underwriters) with more accurate and comprehensive data describing the assets, resulting in shorter time frames to complete due diligence.

- Overcomes travel restrictions to inspect assets.

- Web and cloud-based, providing ease of access with no software to download and install.

- Provides a longer-term foundation for digital transformation, including risk-based inspection and predictive maintenance, and subsequent addition of 3D modeling of corrosion loops.

- Supports regulatory compliance where inspectors and auditors require confirmation of assets and changes over time to correct deficiencies.

Situation and Problem

A midstream operator decides to sell certain assets in its portfolio, including a 200MMcfd natural gas processing plant and compression facility. Both facilities are over 10 years old and have undergone various engineering changes and modifications during their lives, including the replacement of certain equipment and configuration changes in piping, controls and other instrumentation. Both are subject to the recently enacted DOT/PHMSA Megarule requiring operators to have updated as-built documentation of affected assets, as well as OSHA process safety management for certain assets. No updates to P&IDs have been made by the operator since initial construction. The operator suspects that pushing outdated information regarding the assets, including out of date P&IDs, is going to generate a lot of questions. In addition, buyers and other due diligence professionals would potentially want to inspect the physical assets, which is problematic in the current pandemic. Other operators in the industry have similar assets for sale, reflective of the recent market downturn.

Action Taken

The operator made the decision to create a 3D Digital Twin for the to-be-sold assets, and the following steps were taken.

- The operator provided a plot plan to the 3D Digital Twin vendor, who created a “key plan” from that document and Google Earth which indicated the number and location of scanning locations.

- LIDAR scans of the facilities were performed and LIDAR SMEs provided Virtual Reality headsets to facility personnel, and remote assistance was provided as instruction on where and how to perform the scanning.

- Current P&IDs were provided to the Digital Twin vendor, who upon receiving the LIDAR data, updated the P&IDs to reflect as-builts and made them intelligent (auto-recognition of equipment, instrumentation and piping circuits, materials data and specifications as was present on the P&IDs).

- The resultant Digital Twin was uploaded to the cloud and credentials created for users to access through a web browser.

- Entire process, Steps 1- 4, was completed in xx weeks.

Buyers and Due Diligence Professionals Perform Virtual Review

The seller exports updated P&IDs as pdf files with CAD layers from the 3D repository and pushes these files to the VDR. Seller also provides a link and credentials to buyers and due diligence professionals to access the 3D repository. Buy-side is now guaranteed accurate data as well as the ability to perform a virtual inspection of the facility, with the ability to navigate between a plot plan, 3D of the assets, and the intelligent P&IDs. In addition, seller allows the 3D data to be used by buyer Representation and Warranty insurer underwriters, accelerating the issuance of a policy, which allows the seller to pocket a percentage of the deal which would otherwise be tied up in escrow for several years.

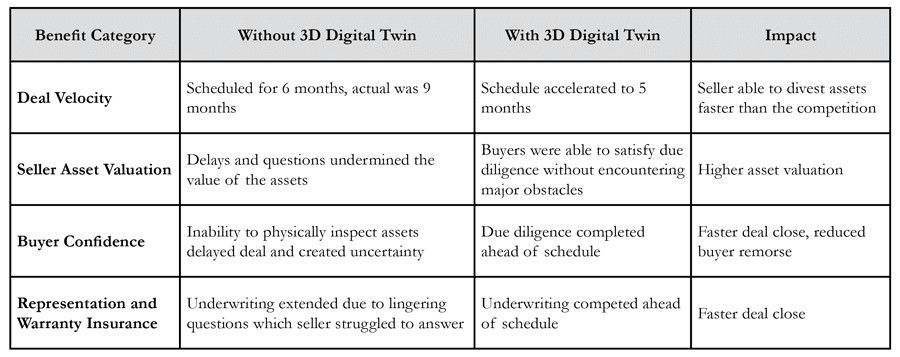

In this case, the use of a 3D Digital Twin provided the following benefits:

Conclusion

Using 3D Digital Twins to support, M&A due diligence is a novel solution which benefits sellers and their ability to move ahead of competing assets which do not leverage this solution. Buyers likewise benefit from increased confidence of understanding what they are acquiring. For M&A activity where there are above-ground assets of some mechanical complexity, using a 3D Digital Twin increases transparency of what is being sold, providing guaranteed accurate data with the ability to perform remote inspection of the assets. Improving deal velocity is the ultimate benefit.

Headline photo courtesy of mCloud

Brent Stanley is the VP business development, Connected Industries for mCloud, and has degrees inmechanical engineering, math and physics from Case Western Reserve University. He has spent the last20 years implementing digital transformation projects for Fortune 500 and industrial companies, including oil and gas and process industries. Stanley is a subject matter expert in adoption of 3D Digital Twin solutions to support mechanical integrity and RBI initiatives and has worked closely with industry participants to achieve regulatory compliance for the operation of assets affected by PHMSA, OSHA andother regulatory bodies.