Even with the fluctuations in demand in the oil and gas industry, the existence of drilling wastes and the need to safely dispose of that waste remains constant. Operators often seek innovative and economical ways to handle, treat and even recover wastes from drilling processes.

Drilling fluid, also known as drilling mud, is a common waste from oil and natural gas drilling. The unique fluids are used to control subsurface pressures, lubricate the drill bit and stabilize the well bore. Drilling mud is pumped from the surface through the hollow drill string and exits through the nozzles in the drill bit. The fluid then returns to the surface through the round space between the drill string and the walls of the drill hole.

Drill cuttings, another common waste, are small pieces of rock produced in the process of drilling through rock to reach an oil or natural gas reservoir. These various sized and textured cuttings are brought to the surface by the drilling fluid.

Drill cuttings are generally disposed of as waste after the drilling operation is finished. Some drill cuttings, though, can be treated and reused, once the petroleum hydrocarbons are removed. Recycled drill cuttings have numerous beneficial applications in both the construction and manufacturing industries. Drill cuttings have been used to stabilize roads and drilling pads, resurface roads and create daily cover at landfills. Reused cuttings may even be used in cement production.

The most effective method for recovering drilling wastes is through thermal treatment, which uses extremely high temperatures to reclaim or destroy hydrocarbon-contaminated materials. Waste streams that are high in hydrocarbons, such as drilling fluids, are excellent candidates for thermal treatment.

One form of thermal treatment, thermal desorption, vaporizes volatile and semi-volatile contaminants through the application of heat. Thermal desorption easily and efficiently removes light hydrocarbons and other volatile organics. The results of the process include solids, water condensate and oil condensate.

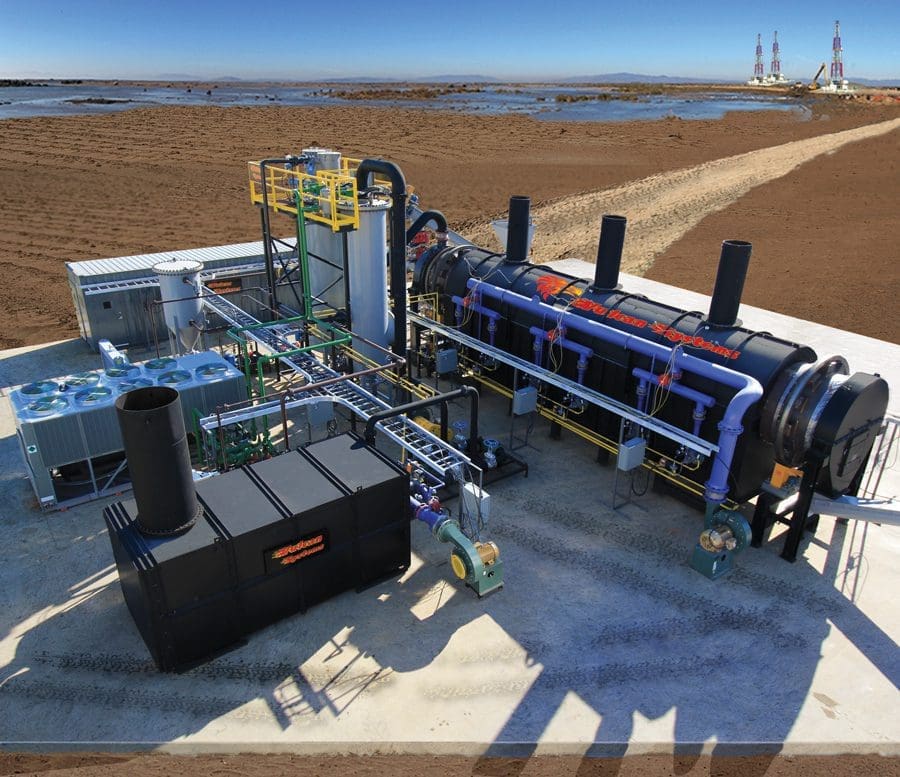

The most common equipment used for thermal desorption is an indirect fired rotary kiln. Rotary kilns use hot exhaust gases from fuel combustion to heat drilling wastes and remove contaminants. The kiln consists of a rotating drum placed inside a jacket. The drilling wastes are transported through the drum as it rotates, moving through a series of carefully placed flights that prevent the material from forming into clay. Heat for the thermal desorption process is provided through the wall of the drum by the hot exhaust gas that flows between the drum and the jacket.

In addition to a rotary kiln, a vapor recovery unit can be used to recover or condense hydrocarbons from the gas stream. Rather than being destroyed, the hydrocarbons may be reused in the thermal desorption process as an alternative fuel source or sold as a by-product. A vapor recovery unit generally consists of a quench scrubber, mist eliminator, shell and tube heat exchanger, knock-out pot, oil/water separator and pre-combustion chamber. Some processes also use a baghouse, thermal oxidizer or acid scrubber.

The operating temperature of the rotary kiln can reach up to 950 degrees Fahrenheit (510 degrees Celsius), and the kiln operates in an oxygen-deficient and slightly negative atmosphere. Vapors from the contaminated drilling wastes are pulled out of the system in a countercurrent direction to the material flow.

The vapor can then be pulled into a high-efficiency quench scrubber using oil as the quench liquid. The quench removes dust particulate, in addition to condensing the heavier hydrocarbons in the vapor stream. The condensed oil and sludge are pumped through a set of filters to an oil/water separator and then to a storage tank.

The vapor that is not condensed in the quench scrubber is pulled through the knock-out pot, which reduces the temperature. The condensed water and oil from the knock-out pot is then pumped to an oil/water separator. The non-condensable gases are pulled from the knock-out pot by an induced draft fan and pushed into a secondary treatment unit, where all remaining hydrocarbons are destroyed at temperatures reaching up to 2,000 degrees Fahrenheit (1,093 degrees Celsius) with a residence time of up to two seconds.

Recovering drilling wastes is an often cost-effective, practical and environmentally beneficial process. Recycling and reusing drilling fluids and drill cuttings can help operators meet disposal regulations, save on disposal costs, reduce truck traffic and save money on building well pads and roads. The proper disposal of drilling wastes prevents contamination of water supplies and the soil, and enables operators to recover reusable drilling fluids, resulting in substantial cost savings while also improving environmental performance.

Vulcan® Systems, formerly Worldwide Recycling Equipment Sales, provides custom-designed thermal processing solutions to clients in the oil and gas industry. For more information, visit vulcansystems.com or call 660-269-7502.