With the passage of time, it is increasingly difficult to get trained personnel for the oil industry. The experience as a crane operator, drilling rig, welder, drilling floor engineer among others, will only be achieved with time, and practical knowledge is only acquired with practice.

Worldwide companies use millions of dollars for the training of personnel in these areas, and they still have the risk of some problem when using the equipment they were trained for. This is why it can be highly difficult to find experienced professionals in practical operations such as equipment management in the oil industry.

Faced with this need, the virtual reality industry offers a solution to the oilfield. By bringing together design professionals, architects, mechanical engineers, petroleum engineers and (as a key piece) engineers of the disciplines related to the computational area, such as computer, systems and virtual design engineers.

With the aforementioned ingredients, we expect as a result a functional response to the need for practical staff training, and it has not been fully achieved, but there has been a growing process. Every time, more companies are venturing with these types of tasks and more and more operations are simulated for learning every day.

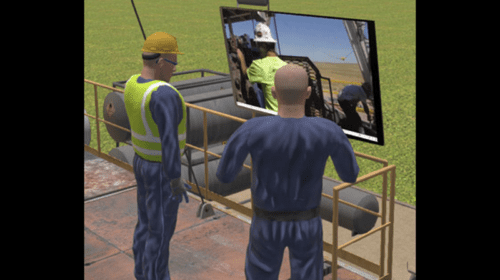

When this type of service is hired, specialists in the area to be trained are mixed together with the virtual reality technology, which emulates the operating controls of the drill (if this is the type of operation to be learned), then every training provides practical and theoretical knowledge by specialists. This undoubtedly translates into less preparation hours and better results regarding staff learning.

The investment when training staff with this type of tool represents a greater amount than the one that’s usually put in professional training with specialists in the area, but the risk of losses due to errors of non-experienced professionals is even greater.

What is This Learning Based On?

With replicas of the original controls to operate drills or cranes in some cases during teaching, the difficulties that the operator can face could be modified, from environmental conditions to the occurrence of blowouts or accidents. It implies going further.

By understanding that there are different types of learning, experienced professionals are used in the training areas, together with the virtual reality simulator. In this way kinesthetic, visual, auditory and reading learning are covered all at the same time.

Nowadays, there is a significant amount of companies that are dedicated to this training modality, but some dare to innovate a bit further.

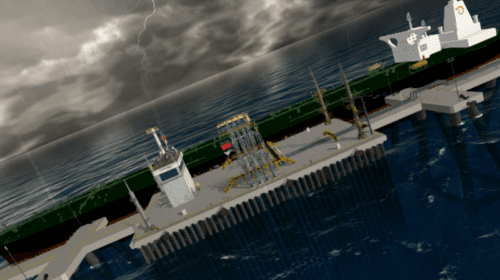

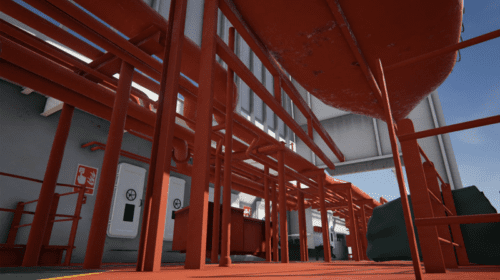

The Optimax MLA Simulator created by Castillo Max, a Venezuelan company, is a virtual reality system that allows the training of Marine Cargo Arms operators. With the use of this simulator, the transition from theory to practice in the handling of Load Arms by operators is facilitated.

This mechanism gets to simulate different environmental conditions as well as different operating protocols, operational emergencies or extraordinary situations; and most important, the arm control scheme, as it includes original handlers of this type of equipment to recreate an experience as close to reality as possible.

The position of marine cargo arms operator is a dangerous work and calls for a high responsibility, not only the component’s integrity is put in danger, but also human lives, like the diver in the bottom of the sea.

On the other hand, we have the Luminous Company from the United Kingdom, which uses laser technology to copy scenarios, that is, with the structures scanning, you can create an exact copy of the location so the public can learn from the processes in the same place where they will be working.

Despite not having controls schemes that are normally used in the oil and gas industry, this system allows the personnel training in the most important field: safety. Using a 3D scenario with virtual reality in real time, it shows workers the structures to be occupied in their day-to-day labor, with the use of casual examples such as putting out the fire, picking up tools on the floor or a check list to achieve the basic instruments of protection.

Luminous offers to companies the ability to train people with real structures, either offshore or on land by changing environmental conditions or by varying the possible problems that the worker may face.

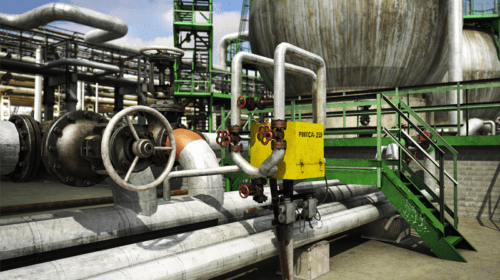

Unigine is the Russian company pioneer in the use of virtual reality for personnel training, although it moves a little away from the drilling floors, it focuses on one of the sectors with the most exposure to danger the industry has: the refineries.

In the past, accidents registered in refineries were due to lack or neglect of maintenance tasks. This is why Unigine has an Interactive Maintenance Training program that uses detailed virtual scenarios in which the apprentice can do several things, from moving into the premises to doing maintenance work to a power box, in order to start a process cooling pump, and thus avoiding an accident in the future.

In the refineries arduous search for qualified and attentive personnel, Unigine shows great progress, despite not having extreme emergency situations, as could happen in some cases, it gets very close to what is necessary for the development of common activities in a refining plant operator’s day.

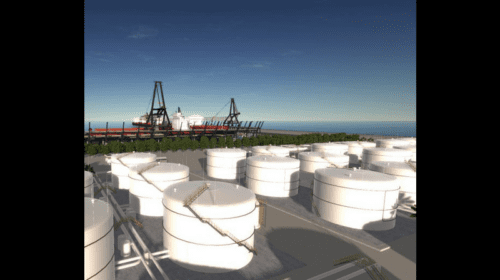

Q-bit Technologies, located in Palo Alto, CA, represents one of the most important presences in VR training for the oil industry, because it covers areas such as lifting, on land and offshore drilling, refinery, and the implementation of virtual classrooms.

They use the internet to provide theoretical training in virtual classrooms, and practice sessions in real time from anywhere in the world.

And We Wonder, Why Virtual Classrooms?

Well, in this line you have the duality of sharing classrooms with other people from other countries with rich experiences. At the same time, you can carry out drilling practices with people worldwide, who occupy different roles on the drilling floor or in refineries, depending on the chosen type of training. In this way, they could not only save time, but also money, since only the VR equipment and an internet connection are needed.

- Among the qualities of Q-bit are:

- Industrial Machinery and Procedures VR training

- Risk and Safety VR Training

- Oil and Gas, Drilling and Refinery Simulators, Oil & Gas VR Training

- Hospital and Emergency Care Procedures VR Training

- Soft Skill and Management VR Training

- Collaborative VR Workshops and Virtual Reality Classrooms

- Collaborative VR Training Environments

- Virtual Reality Collaborative Training Simulations

After analyzing the different advances in VR technology for the oil industry, it shows that there is a long way to go. Although the demand is high, what the oil and gas industry looks for every day is highly trained personnel, which can be reliable for different practical activities such as drill, cranes and marine arms manipulation, or refinery processes to name a few.

The pending subject of this training modality would focus on the actual equipment controls and on being able to simulate experienced situations in order to prepare their staff, not only to face the ideal scenario, but also the most difficult tasks, such as a pressure increase during drilling, as an example.

It is expected that one day VR simulators can train a diver and a sub-marine arm operator in real time, by using the North Sea waters as a scenario, among other activities. Apparently, that day is nearer that we think.

Therefore, it is not an easy task for VR engineers joined with the oil and gas specialists, but in terms of security, the sum invested in training and safety is usually not restricted in the oil companies. For this reason, the VR appears as an option with more and more importance.

Andres Ocando is a 30-year old petroleum engineer, who has been working for PDVSA for five years, facing positions such as reservoir engineer and geomechanical engineer. He currently works as a project analysis engineer. There, he has optimized the data collection process for the development of geomechanical models. Ocando has experience in copywriting and is currently a technical writer on topics related to the oil and technology industries. He collaborates for important technical publications such as OILMAN Magazine and SPE. Quality and responsibility are two words that describe him perfectly. Ocando is currently pursuing higher studies at the University of Zulia to obtain his master’s degree in petroleum engineering.