“Capacity” – one of the most aggravating, yet one of the most common words coming out of West Texas and Southeastern New Mexico today. Production is at record highs, almost doubling within the past ten years, but exploration and production companies are having to ask themselves what they are going to do with the crude coming out of the ground. With high demand markets in Asia and Europe, the value of crude sitting in lease tanks is nothing compared to the price of crude that has made its way to the Gulf Coast for export. The Permian pipeline bottleneck, the increased requirements to provide a quality product, along with port vessel constraints have created unpredicted challenges for these companies.

Pipeline Constraints

For starters, they need more pipeline capacity. Midstream companies are changing the flow direction of their pipelines to remedy the capacity issue, transporting imported crude so that these pipelines are now likely to flow toward the Gulf Coast. Additionally, some NGL pipelines have been converted to transport crude oil. However, this has only functioned as a band-aid to a broader problem. Currently, over nine new pipelines have been proposed in the region and are expected to be completed by 2021. These pipelines will provide relief with additional capacity of about 5,000,000 barrels per day.

Quality Concerns

Permian producers are also concerned about protecting the quality of their crude coming out of the ground. With an increase in light crude coming out of the Permian recently, producers are also asking midstream companies to keep intermediate barrels separate from light barrels and minimize the interface between the two. By not comingling the different grades, the commodities remain pristine for their respective downstream markets.

To meet this expectation, midstream companies need to provide three things to producers:

Consistency: Producers want to know that the quantity and type of barrels that they put into the pipeline are consistent with the barrels they take out of the pipe. This ensures that their downstream markets are going to be satisfied with the crude they will refine.

Accuracy: Producers want to know that a barrel will reach its destination when the pipeline company says it will. This allows the producer to market the products more reliably and schedule additional downstream transportation as necessary.

Characteristics: Producers want to ensure barrels they put into the pipeline come out of the pipeline without excess additives like drag-reducing agents and other contaminants. Downstream markets may start declining a producer’s crude if it’s difficult or more expensive to refine.

Vessel Management

Exporting crude is the main target for Permian producers, leading midstream companies to become more and more creative in how they avoid some of the historical constraints. However, these types of projects are costly, slow to approve, and they take several years to build. An example of these capital-intense projects is modifying ship channels to become deeper and wider, which allows more traffic and larger vessels to access their docks. Other companies are evaluating building offshore docks to avoid these constraints altogether. All of these solutions to the bottlenecks may take five to ten additional years before they are resolved entirely, so streamlining today’s processes will help Permian suppliers distribute their product more quickly.

Also, marine terminal and dock owners can facilitate export services by providing better:

Location Awareness: Ensuring capacity at marine terminals is critical. Having tankage to store the abundant supply and being able to load that volume onto vessels with quick turnaround is crucial.

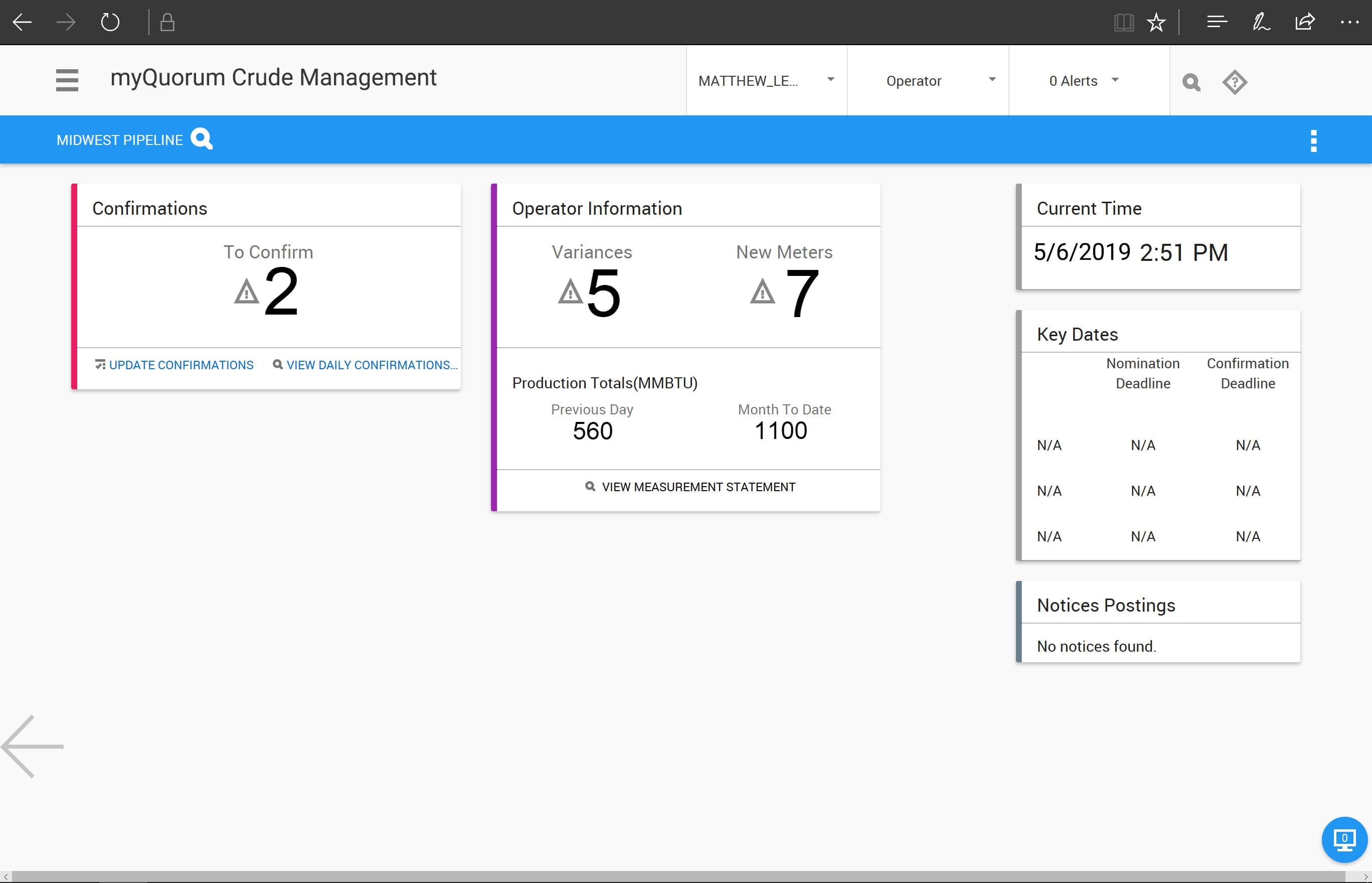

Timing: Dock owners need the ability to schedule vessels to the berth accurately. Understanding the timing of vessels coming in, de-ballasting, and loading of crude allows their shippers to avoid idle time in waiting for the berth to become available. Software companies such as Quorum offer vessel scheduling to maximize dock usage and throughput to streamline this process.

Optimization: Terminal operators benefit from tracking incoming volumes along with outbound vessels to maximize their use of capacity. This prevents the need to reroute crude, shut-in production, and leave vessels waiting in the bay. Software is critical to optimize these processes. Companies such as Quorum provide solutions that assist with pipeline scheduling, allowing shippers to know precisely when their barrels will arrive. Quorum also offers terminal scheduling solutions that ensure efficient capacity utilization.

Conclusion

According to Energy Information Administration data, the United States is now the largest oil producer in the world. With that achievement comes many challenges that the industry is working to overcome. First, much-needed pipeline capacity is being added to take crude from the Permian to the Gulf Coast. Second, higher standards are helping address product consistency and quality expectations alongside software that provides better visibility into processes. Lastly, vessel management, such as size accessibility, scheduling, and tracking, has become vital in helping the Permian move their product.

Ryan Cowan is a Senior Manager in the Solution Design group at Quorum. In this role, Mr. Cowan is responsible for the oversight of the myQuorum Crude Transportation program engaging with several of the largest liquid pipeline and storage companies in North America. With 8 years of oil and gas experience, Mr. Cowan has engaged with over a dozen midstream Fortune 500 companies in both the oil and gas space. Mr. Cowan has a BBA from the Rawls College of Business at Texas Tech University.