Graphene is a sub-derivative material of the most abundant element on our planet: carbon. Known by scientists as the miraculous material, graphene is positioned as the biggest dream of manufacturers of materials such as spaceships, pipes protective covers, computer parts, auto parts for both bodywork and engines. It has also become the perfect compound for batteries and phone screens, computers or submarines. This is just a small list of all the utilities this material has.

The first quality of graphene is that it is extremely light, but tremendously strong at the same time: a 1 m2 layer weighs only 0.77 grams. It is transparent, flexible, waterproof, does not pollute and it’s harder than a diamond, 200 times stronger than steel and more flexible than carbon fiber. It is also a super conductive: 100 times faster than the silicon used on chips.

It conducts heat, generates electricity when it receives light, and changes its properties when combined with other materials. For example, it can repel water or be more conductive.

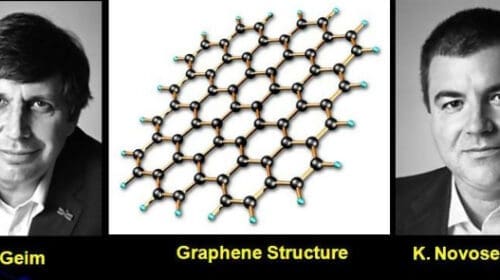

Initially discovered in the 1930s, graphene did not acquire any importance, because in order to produce a small piece of it, high pressures and temperatures had to be used, but not until 2010 when two Russians, Andre Geim and Konstantin Novoselov, won the Nobel Prize in Physics for discovering a new method for a more stable graphene production.

Quoting the article written by these scientists about graphene, this material “is a form of carbon. As a material it is completely new – not only the thinnest ever but also the strongest. As a conductor of electricity it performs as well as copper. As a conductor of heat it outperforms all other known materials. It is almost completely transparent, yet so dense that not even helium, the smallest gas atom, can pass through it. Carbon, the basis of all known life on earth, has surprised us once again.”

When we turn to the oil and gas industry, we need a material that can be resistant to pressure, compression, abrasion, and at the same time, that has a significant flexibility or hardness to be capable of conducting electricity in voltages equal to or greater than 480 Volts. Also, we need it not to be destroyed or weakened in approximately 15 years, which is the average usage time that an electro submersible pump is kept on the ground before it is necessary to apply corrective maintenance.

With such a bold material it is necessary to go through each sector of the industry to see in which applications it could improve the oil and gas field.

Subsoil

Every day that goes by, there are fewer conventional reservoirs and it is necessary to use more resources to access unconventional ones. The first difficulties when facing these deposits, are the adverse conditions that the operator faces.

A reservoir placed in the Triassic age, can face pressures above 12k psi, or temperatures greater than 400 ° C. To these conditions is usually added the existence of contaminating fluids, so that a metal pipe with tungsten carbide alloys works, but after a period of time, it jeopardizes the well, whose investment tends to exceed an amount of 7 digits.

The graphene, even when it’s 200 times thinner than a sheet of paper, is capable of coating the casing and production pipe to shield subsoil equipment that was compromised in the past, because it is so slim that the commonly used diameters would not be affected.

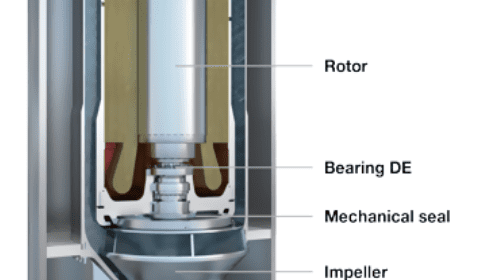

In addition to this, it is advisable to use the lifting method known as BES (Electro Submersible Pumping), when it comes to ultra-deep wells, since this technique has the highest volume of production, but it also tends to be the most expensive one. One of the main expenses of this type of pumps is the power cable, which is responsible for carrying energy from the surface to the bottom.

The ability to conduct 200 times more electricity than silicon, offers us a much thinner power cable than commonly used, which is also more reliable in terms of power. On the other hand, we have its resistance to the different pollutants that are exposed and a power cable designed to resist much more than the one factories tend to use.

The deadly enemies of bombs are abrasion and corrosion. While having a minimum of revolutions of 3500 rpm, there is no time to filter the fluids or to make a separation of them while facing the pollutants, so the use of graphene becomes an important option.

The BES system consists of a centrifugal pump that drives the fluid to the surface. In these cases the passage of liquid fluid is the pump’s cooling agent, so when there is gas, the pump suffers severe damage, since it tends to overheat. If we use graphene to build the pump, we avoid damage and corrosion by abrasion and pollutants in the first instance.

Thanks to its ability to be combined with other elements, we can make a graphene alloy for heat dissipation and thus we’ll have a BES system capable of working with larger amounts of gas, besides being much stronger over time.

Exploration

In addition to metal-like capabilities, graphene is the best sound conductor that exists, capable of moving waves or receiving them with a precision that’s never seen before. Sound companies with IHiber or Beats use graphene for their special equipment.

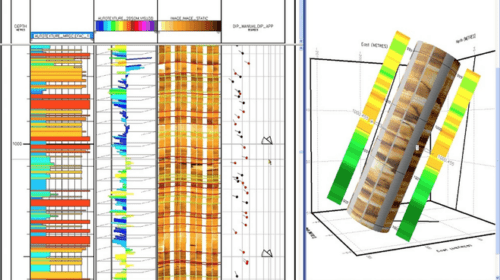

In the exploration sector, one of the most important studies ever made is the seismic research. It’s carried out with the emission of sound waves that travel through the subsoil, returning to the surface and being captured by receivers. Using graphene would highly improve the emitted and received signals, and this way the sharpness of the subsoil images would be optimal for geophysicists, substantially supporting exploration work.

Not very different but just as important are the sonic records offered by many service companies. These records allow to recreate an image of the formations that are being traversed during drilling and are using the principle of bats. They allow to see the micro fractures, fractures and, in the best cases, to recreate a 3D view of the formation. Likewise, when having a better sound emitter and receiver with graphene, the quality and certainty of the results would be neat and fully functional.

At the same time, it provides the opportunity to be used in cases such as the Pearl Deposits in Venezuela, gas fields located in the northwest of the country. This deposit presents one of the largest gas reserves in South America close to 15 trillion cubic feet of gas, but with the difficulty that in its generating rock is born, besides gas, the mercury metal, that makes sustained production impossible, (mercury is a highly toxic and corrosive liquid metal).

One of the few metals capable of tolerating mercury at high pressures is graphene. Using a thin layer of coating, so thin that it would practically not affect the diameters of the pipes, good oil extraction can be achieved with few durable wells over time.

Surface

The surface equipment has a double degradation: inside pipes, heads, separators and valves passes the fluid produced that sometimes contains highly corrosive pollutants. To this we add environmental conditions such as the arid areas of Africa, the strong sea waves from the north, the abrasion of the sands in the area of Arabia among other things. The use of graphene as protector of these equipment would be the best option.

Surface separators fulfill a crucial task: when the fluid is produced and arrives to surface, its pressure changes, so it releases aggregate fluids that come as solution such as gases or water. And since water is a natural oxidant, any gas that travels in the triple solution of oil, gas and water can become a lethal acid, for this reason the three-phase separators are responsible for preventing the trip of these three fluids in a flow line that could later reach storage tanks.

Separators tend to be large, robust and heavy tanks and need an important maintenance to avoid deterioration. When using graphene to cover the tank, we reduce the impact of corrosion by contaminants. On the other hand, graphene can be used on the internal shock plate that has the separator, because in addition to being resistant, the vibration thrown by the plate would provide a better detachment of the gas and water atoms that joins the oil. This way, a cleaner oil will travel in the flow line.

Given So Many Uses and Solutions, Why Not Graphene?

Despite the discovery of a more stable method of producing graphene, it still has a very high cost. Besides this, the oil and gas industry is one of the world’s commercial activities that generates the highest amount of money, so it can easily makes sense to ask why grapheme isn’t being used industrially today.

Raul Palencia is an engineer and researcher with more than 10 years of experience as a geologist. He graduated from the prestigious University of Andes (ULA), later he received a master’s degree in reservoir engineering at the Venezuela Hydrocarbons University. During his career development, he worked for oil companies in positions such as: field geologist, reservoir engineer and reservoir simulation. He has worked in Argentina, Ecuador, Mexico and Venezuela. He currently resides in Texas.