While there are some who may still wax poetic about the days of cassette tapes, CD players and boomboxes, reports show that Gen Z represents roughly one quarter of the oil and gas workforce. Still, there are probably some of you reading this who do not know what those things are or how they work. In the advent of Napster, LimeWire and the ensuing revolutionary shift in the monetization model of the music business, record labels, music artists, movie studios and a vast majority of the film and music entertainment, business caused an uproar over the perception that artists would have no way to monetize their craft anymore and these downloads would be a death knell to the industry and was paramount to theft.

In truth, the industry evolved to create innovative revenue streams and is better off for it today. The ubiquity of music through streaming and other platforms has positively democratized the business and changed the game forever. There are numerous similar examples, yet human nature is to be skeptical of change until the requisite trust is built through time, adaptation and familiarity. As the world progressed from horses to cars, candles to electricity and printing presses to telephones, there were certain jobs that became obsolete or dramatically changed in scope upon the onset of these new protocols. Some of these workers took on other roles within the same company or industry, some found occupations in other industries, and some would simply automate elements of their workflow but kept their position due to the inherent nuance required to do the job effectively.

Arguably, the most impactful result of these leaps forward in technology and the correlated efficiency has repeatedly been the litany of new niche markets, products, services and support staff these new positions and industries require. For example, Global Market Insights has projected that the digital oil field market will exceed $35 billion by 2026 and the intense focus on the environmental, social and corporate governance (ESG) elements of the energy business will require significant manpower to support those new standard operating procedures.

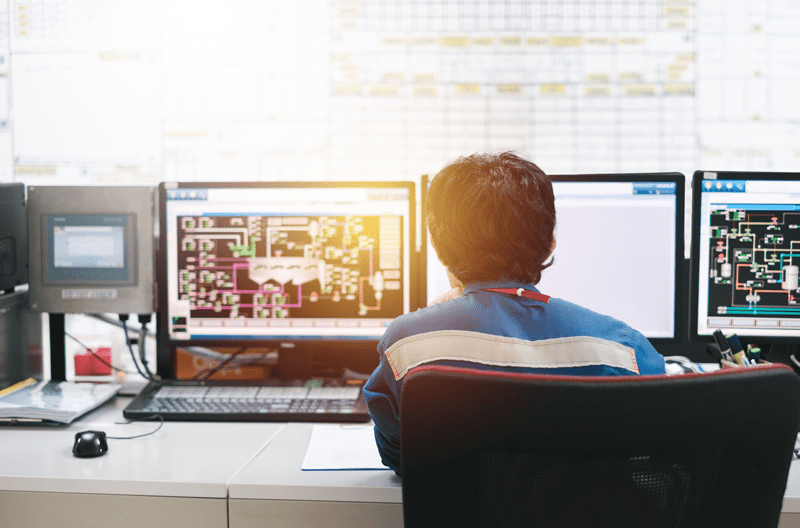

Further, recent reports indicate that approximately half of overall tasks done by humans today could be automated with current technology. The AI-driven predictive analytics and preventative maintenance capabilities already deployed in the field have enabled firms to more accurately and quickly strategize, operationalize, troubleshoot, monitor and revise operations. A significant barrier to entry for many firms, at this point, is the availability of employees with the skills necessary to collect, analyze, interpret and operationalize all of the available data without bias, as the director of data science at CLARA analytics, Jia Li, pointed out in a recent Forbes article.

“To build this team in-house, you will have to hire more than just data scientists. Full deployment of a new solution requires product managers, software engineers, data engineers and operational experts to develop process and operational workflows, staff to integrate data models into operations, people to manage onboarding and training of the employees who will ultimately use the solution, and staff who can quantify value generation.”

Operators with insufficient or incomplete data, whether from poor records, faulty measurement instruments, lackluster maintenance standards or other factors are in constant “firefighting” mode to tackle the next critical issue to come up on one of the sites they oversee. In an industry which continues to be starved of liquidity, stability, supportive regulation and investor confidence, accurate and real-time data powered by AI is the next giant leap forward that will keep the men and women of our industry out in the field and the rigs continuing to break ground with increasing efficiency, profit and safety; however, AI is only as good as the input data it is trained on, so implementation is critical. To add to the complexity, the oil and gas industry has some bad habits regarding accurate data across an entire operation, often experiencing gaps in these data streams, which can be problematic at the automation stage. Gigabytes upon gigabytes of data are generated daily at each and every wellsite and, if any inherent biases or other disruptive anomalies are introduced into the “training” of the AI, the output will mirror these flaws in its calculations and determinations.

“Digitalization will be the backbone of the energy transition,” says John Markus Lervik, CEO and co-founder of Cognite. “Instant access to trustworthy contextualized data for better business decisions will transform the industry. Those who invest in their digital agendas and focus on scalability and democratized user enablement will continue to lead the way and increase sustainability, safety, effectiveness and profitability in the process.”

There will be opportunities for workers who were displaced by the automation process to fill these roles once they are properly trained. Coupling the expertise of engineers, geologists, landmen and others with the predictive power of AI will yield far better results than either physics or pure AI could attain singularly. In an exceedingly competitive, complex and challenging industry like oil and gas, increasing efficiency, decreasing downtime and quickly adapting to new environments are all collectively and individually critical to long-term success.

While traditionally slow to adopt new ways of doing things, the industry recognizes the immense potential of artificial intelligence (“AI”) and machine learning (“ML”), which is a subset of AI, and the ball is only beginning to pick up steam, rolling downhill in the last couple years. As AI software and hardware incremental costs decrease and opportunity costs increase, there are innumerable ways in which downstream, midstream and upstream firms have and will continue to incorporate machine learning into their operations. According to the 2020 New Directions, Complex Choices study, published by DNV GL, 85 percent [of survey respondents] expect to maintain or increase spending on operational asset efficiency in 2020, while most (80 percent) will also maintain or increase investments to extend the life cycle of their existing assets.

“In our industry today, we waste so much time redoing things,” says Julie Cranga, vice president Subsea, at TechnipFMC. “We are too document-centric; engineers have to spend too much time trying to access reliable information. We see digitalization as a way to solve these issues, boost our efficiency and reduce our costs. It is also a way to help us reduce the number of people we have offshore. This is mostly because we want to limit risk, but it also helps lower costs.”

Over just the last eighteen months, we have seen Microsoft and Halliburton announce a strategic agreement to enhance Halliburton’s digital platform and build out the framework to support these automation initiatives across every division of the company; the University of Houston open the Artificial Intelligence Industry Incubator and Digital Oilfield Lab; data giant Enverus DrillingInfo’s primary financier sell a majority interest to a private equity firm with a focus on SaaS solutions; the Department of Energy (DOE) announce a $35 million grant to support clean energy and climate solution technology research; Egypt and Schlumberger collaborate on an initiative to model the national subsurface estate through enhanced modeling and numerous other major announcements. The race to refine and enhance these tools and reap the benefits is on; those that choose not to innovate will be left behind to slowly dissipate.

Ben Samuels, CEO of Source Rock Midstream, and chief growth officer of Blu Capital Resources, is an entrepreneur focused on the energy markets with an innovative and collaborative approach to the issues facing the industry today. Based in Midland, Texas, since 2014, Samuels has had a front row seat to the boom-and-bust cycles of energy investment and development, which has helped form his view on the markets, domestically and internationally. Samuels is a stakeholder in a litany of ventures across the energy markets value chain, with an emphasis on value creation, innovation and risk mitigation. His podcasts, Don't Let The Facts and Coffee & Liquidity, and body of work for The War Room, Oilman Magazine, Energy Brushback Insider and others, all speak to Samuels’ motivation to be a voice for the underserved and a positive force in the lives of those around him. When he is not producing content for these channels, he can be found immersed in other passions such as sports cards and cooking. Find Samuels on Twitter: @baspermian