The ability to ensure pressure control equipment is in good condition in offshore areas is a fundamentally important factor that helps to ensure the safe, low downtime, and longer life of the equipment. Consegic Business Intelligence analyzes that Pressure Control Equipment Market size is estimated to reach over USD 8,047.56 Million by 2031 from a value of USD 5,146.50 Million in 2023 and is projected to grow by USD 5,350.61 Million in 2024, growing at a CAGR of 5.7% from 2024 to 2031. Given that the marine environment is extremely harsh, including the high-pressure, corrosive atmosphere and the logistics offshore location, effective maintenance practices have become an absolute must for ensuring risks are mitigated, and operational efficiency is maintained.

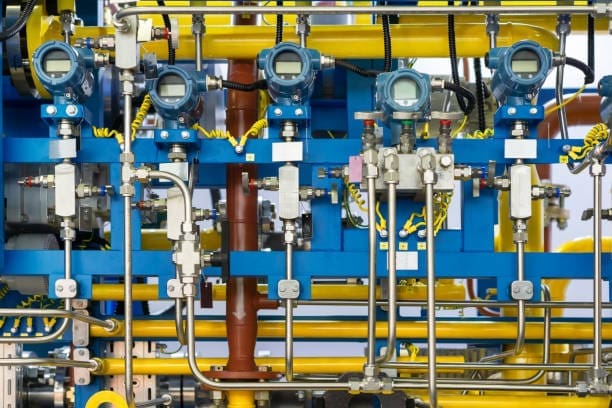

Preventive and predictive are both the main strategies that help to prolong the life of the equipment in offshore areas of pressure control. Preventive maintenance is the practice of planned maintenance tasks and replacements of components that make the equipment still viable or in good condition. This may involve periodical cleaning, lubrication, and inspection of seals, valves, and pressure systems for the sake of early prevention of unexpected failures.

Meanwhile, predictive maintenance is a technique that utilizes data analytics and IoT-linked sensors to obtain real-time monitoring of equipment performance. Thus, these data are accumulated, and from them, the operators can draw conclusions on the situation of each component and interpret the situations when repairs or replacements are necessary. This technique is therefore not only limiting the outages, which are usually not planned but also helps avoid the minor problems that might accumulate and eventually result in serious equipment failures.

Offshore environments are characterized by factors such as flooding, the high concentration of salt in water, and other corrosive chemicals to which pressure control equipment is exposed and which, through time, might wear out the metal components. In addition to that, companies should also use corrosion-resistant coatings and choose suitable materials in harsh environmental conditions.

Frequent inspections for corrosive wear, especially on susceptible surfaces, can be instrumental in the identification of early stages of the wear and tear process. When corrosion is discovered, equipment should be cleaned and treated to reduce further deterioration. Cathodic protection, the process of making the metal the anode in a given electrochemical cell, which guards metal surfaces can also be useful in terms of rust prevention.

Seals in pressure control equipment are very important in keeping the fluids and gases under high pressure. Nonetheless, seals are the materials that change from water to vapor, therefore the operational strains on offshore seals are temperature fluctuations, mismatches in pressures, and the frames exposed to chemical exposure. Inspection and maintenance of seals are crucial to ensure that the seals are in good condition.

Best practices include using high-quality, durable sealing materials suited to the offshore environment. Routine checks for leaks and pressure irregularities can help identify faulty seals before they cause larger issues. If a seal shows signs of wear or degradation, it should be replaced promptly to maintain equipment integrity and prevent pressure loss or leaks.

Remote monitoring technology is invaluable for maintaining pressure control equipment in offshore environments. IoT sensors and automated monitoring systems can track key metrics like pressure, temperature, and equipment vibrations, transmitting data in real time to onshore facilities.

This remote monitoring enables continuous oversight without needing frequent on-site inspections, which can be logistically challenging and costly in offshore locations. By analyzing this data, operators can identify abnormal patterns, such as pressure fluctuations or unusual vibrations, which may indicate potential issues. This proactive approach reduces the need for emergency repairs and allows for data-driven maintenance scheduling.

Pressure control equipment must meet strict safety and regulatory standards, particularly in offshore environments where the stakes are high. Regular audits, safety checks, and compliance assessments are necessary to ensure that all equipment adheres to industry standards.

Standards such as those from the American Petroleum Institute (API) and the International Association of Drilling Contractors (IADC) provide guidelines for maintaining pressure control systems. Adhering to these standards helps offshore operators maintain a high level of safety, ensuring that equipment is capable of withstanding extreme pressures and environmental conditions.

Conclusion

Effective maintenance of pressure control equipment in offshore environments requires a proactive, comprehensive approach. By implementing preventive and predictive maintenance programs, focusing on corrosion control, ensuring seal integrity, leveraging remote monitoring, and maintaining compliance with safety standards, operators can enhance the reliability and safety of offshore pressure control systems. With these best practices, offshore operations can maintain high performance, reduce downtime, and mitigate risks associated with operating in one of the most challenging environments.