Borealis has set the stage for Sweden to drastically increase XLPE manufacturing capacity thanks to two new projects that will position the European nation at the forefront of the energy transition. Cross-linked polyethylene is essential for the energy industry as it enables the safe transportation of power through insulated cables that power the world. Now, Sweden is set to boost its manufacturing capacity for XLPE thanks to Borealis.

Borealis announces two major investments in its XPLE production facility

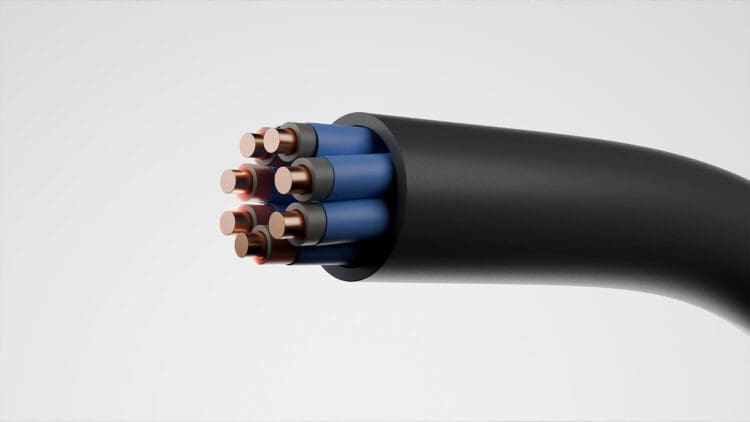

Insulated cables are essential not just to the European energy market, but the global one as well. With the expansion of the global energy market, XPLE facilities have become an essential tool to expand the production of insulated power cables for the international energy market.

Borealis has recently announced that it will make two substantial investments that will boost the company’s XPLE manufacturing capacity at its site in Stenungsund, Sweden. These two investments will position the company as a regional leader in the manufacturing of insulation materials used in medium, high, and extra-high voltage power cables.

Borealis expects the first project to boost MV XPLE capacity

The first project that will receive the substantial investment from Borealis is aimed at expanding capacity for MV XLPE at the Stenungsund facility. The project will construct a new unit specifically designed to manufacture insulation grades used in medium-voltage power distribution cables.

The unit will produce a new-generation homopolymer XLPE grade that matches Borealis’ already impressive manufacturing grade portfolio while delivering a substantially lower carbon footprint through an optimized production process. Borealis expects commercial availability for the project in Q1 of 2027.

The new year brings with it a wave of potential for the international energy market

While some nations are focused on increasing energy output capacity from the oil and gas markets, and others outline plans for substantial investments in renewable energy, Sweden is positioning itself to serve the XPLE market through its significant investments in its portfolio.

The second project that will receive the substantial investment from Borealis involves the manufacturing of advanced XLPE grades used in high- and extra-high voltage alternating current (AC) and direct current (DC) cable systems. These are essential for enabling large-scale power transmission and reinforcing national grids.

Construction on both upgrades at the Stenungsund facility is set to kick off this year, with Borealis expecting commercial viability in 2027. As several nations and companies outline refinery upgrade plans, Borealis is aiming to expand its XPLE manufacturing capacity this year.

“We’re continuously investing in innovation and optimizing our product portfolio to meet the evolving needs of the energy industry. This expansion at our Stenungsund site strengthens our ability to keep pace with growing demand for advanced insulation materials and enables our customers to deliver the power cables that make the energy transition possible.” – Craig Arnold, EVP Polyolefins, Circular Economy Solutions and Base Chemicals, Borealis

As the needs of the international energy market shift, Borealis is aiming to lead the market into the new year with an upgraded XPLE manufacturing portfolio that will position the company, and Sweden overall, as the go-to destination for high-quality, market-leading XPLE cables that are essential for the global energy industry.

The ever-changing energy market requires innovative solutions from companies

With the new year well and truly underway, the international energy industry is faced with a troubling question: what future is there for traditional energy generation in a world that has been consumed by the calls to integrate more renewable energy projects? With nations like Australia set to break ground on new biofuel refineries this year, it has become evident that the market is in a constant state of evolution.