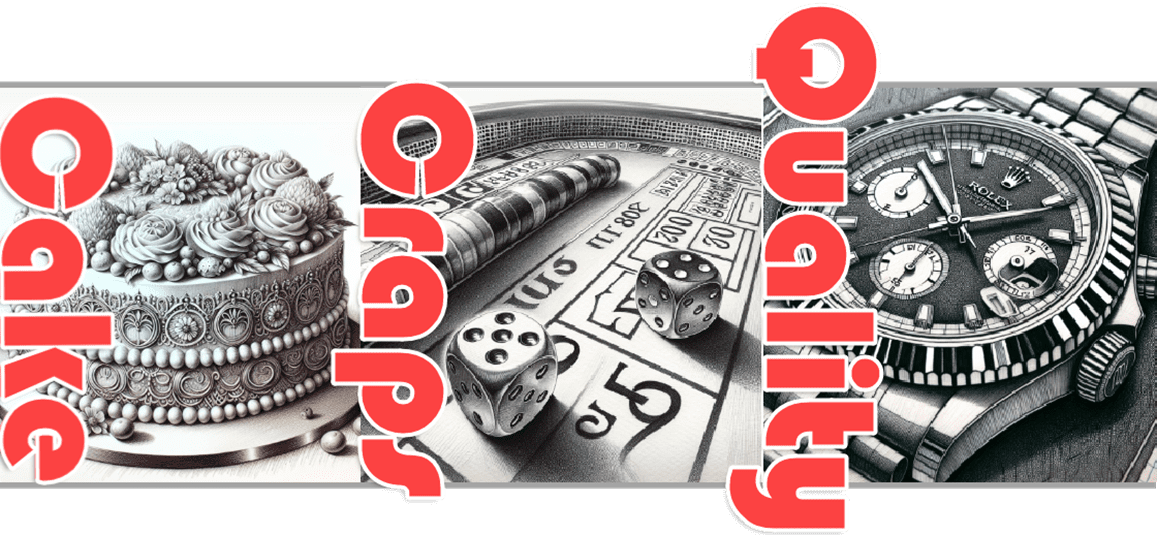

Craps is a game of chance played with two dice, where the outcome is unpredictable, much like a risky business venture—hence the term crapshoot. (Source: Merriam-Webster Dictionary).

In project management, Quality Assurance (QA) is crucial to ensuring that a contractor’s or supplier’s deliverables (equipment and materials) meet specified standards. Effective document QA comprises two key elements:

- Identifying required documents and their submission timeline; and,

- Reviewing and accepting the submitted documents.

Do your projects manage this process effectively? If not, you might as well be rolling dice at the casino. It’s time to ante up.

Like in a game of craps, inconsistent QA practices can lead to unpredictable results – where project deliverables likely miss the mark. Without a robust QA process, managing documentation can become a gamble instead of a certainty.

Is your project following best QA practices, or is it just a quality crapshoot? Do the submitted documents genuinely add value, or unnecessary costs and clutter?

This article breaks down the essentials for documentation success and explores how poor practices can turn these efforts into a roll of the dice. Let’s dive in.

Document Submittal

The timing and type of documents submitted by the contractor or supplier are typically detailed in the purchase order (PO); missing even one critical document in the PO can lead to additional costs, rework, or delays. Requesting unnecessary documents can have a similar result.

Pro Tip: If a document package is too large, such as a manufacturing record book (MRB) or turnover package (TPK), break it into manageable sections.

Projects that clearly define documentation requirements upfront are far less likely to face problems later. This clarity reduces confusion during submission and review, keeping the project on track and within budget. It’s much better to cash out at the cashier’s cage than withdraw from the ATM!

Document Reviews – Before, During, and After

Documents are typically reviewed for acceptance at these project stages:

Stage 1: Before Production

- This review ensures calculations, drawings, and procedures meet project requirements and are suitable for use. Documents typically submitted before production include:

- Calculations;

- Drawings;

- Inspection and test plans (ITPs);

- Operation and maintenance manuals (O&MMs);

- Non-destructive examination (NDE) procedures;

- Welding procedure specifications (WPSs); and,

- WPS summaries.

- Related: How Smart Projects Review Welding Procedure Specifications

Stage 2: During Production

- As work progresses, documents like material test reports (MTRs) and NDE reports may be reviewed for compliance.

- These documents might be submitted as work progresses or after production (see Stage 3) as part of the MRB or TPK. The review might occur at the contractor’s or supplier’s facility or onsite by an inspector representing the engineering and procurement (EP) company or owner.

- Question: If an inspector has already reviewed and approved documents such as NDE technician or welder qualifications, should they be reviewed again? Probably not – re-reviewing previously accepted documents may add unnecessary costs and delays.

Stage 3: After Production

- This review ensures that the final documents, created during production, meet specified project requirements. After production, all remaining documents are submitted, typically as part of the MRB or TPK. This includes:

- As-built drawings;

- Coating reports;

- Complete ITPs;

- Data reports;

- Hydrotest reports;

- Inspection releases;

- MTRs;

- NDE reports;

- Post-weld heat treatment (PWHT) reports; and,

- Torque reports.

- Question: If documents like NDE procedures and WPSs were already reviewed and accepted before production, should they need to be reviewed again after production? Probably not – this is usually unnecessary and always adds expense.

- Pro Tip: Avoid re-reviewing previously accepted, unchanged documents.

Related: Effective Final Review Strategies for Manufacturing Record Books and Turnover Packages

When QA Becomes a Quality Crapshoot

At first glance, QA of document submittals seems straightforward: specify, acquire, review, and accept. Easy, right? Not so fast.

Many projects do identify the necessary documents for submission, but problems arise when there are no clear instructions on how to review and accept them. This can turn QA into a quality crapshoot, where inconsistent or incomplete reviews lead to unpredictable outcomes.

Personnel are busy. With multiple administrative tasks, meetings, and attending to endless communication channels (e.g., Teams chats and email), project personnel may lack the time or training to properly review technical documents. This can lead to incomplete, rushed, and unfocused evaluations. The review process can be time-consuming, especially when managing documents across multiple projects through an engineering document management system (EDMS). It’s akin to hoping for a lucky roll at the craps table. Rework often adds complexity, requiring multiple reviews instead of one.

Critical files are sometimes inaccessible. Sometimes, the specified requirements are not easily accessible or referenced, making verification of their completeness and correctness a gamble. For example, if the PO is stored in a protected folder or unknown cloud location, relying on less reliable sources (e.g., a random drawing in a folder or hoping the contractor-supplier got it right) becomes a risky gamble that could scuttle project success, impacting future expansions or operations.

Personnel are pressured to complete reviews on time. Pressure to stay on schedule often forces rushed document reviews, compromising thoroughness and increasing the risk of overlooking critical details. Questions like: Are these WPSs good enough? And: Can we move forward? are common. Without clear instructions, progress becomes a gamble.

Pro tip: A poorly conducted review may not seem risky, but if a subpar review is considered acceptable, what’s the point of doing it at all?

The intended application of some documents may be unknown. Without knowing the intended application of the WPS (e.g., low-temperature or sour service) or lacking access to the PO and technical requirements, a proper review isn’t only unlikely – it’s impossible. For instance, a WPS for carbon steel pressure equipment requires specific tests depending on its service: Charpy V-notch testing for low‑‑temperature service and Vickers hardness testing for sour service. A WPS designed for low‑temperature, sour service can be used in normal conditions, but the reverse isn’t true. Without knowing the intended service, it’s impossible to verify that the WPS is fit-for-purpose. Accepting it blindly is no better than perilous guessing and gambling.

WPS Cake Recipe: Birthday or Wedding Cake?

A WPS is like a cake recipe. It lists the necessary ingredients (e.g., consumables, metals, and testing requirements), but without understanding its purpose (i.e., service conditions), how can you tell if it’s appropriate? You can’t. Accepting documents as-is without proper context or verification is a gamble that can fail, much like sending a birthday cake to a wedding.

Reviewing WPSs is similar to baking: just as a baker needs the correct ingredients and a recipe (instructions), a WPS reviewer needs detailed information about the application and technical requirements to confirm it fits the intended service.

Birthdays get birthday cakes; weddings get wedding cakes. Well-run businesses deploy robust processes … and gambling is for fun. And never the ‘twain should meet.

Taking Action

QA for documentation can quickly become a quality crapshoot without clear instructions and thorough reviews. Relying on luck or hoping things will sort themselves out is fine for the casino, but it’s a recipe for disaster in project management. Only businesses destined for failure leave project success to chance.

Bake the correct cake. Don’t gamble with your project’s success. Avoid turning your documentation QA into a risky bet – we are here to help ensure your project succeeds. Contact the KT Project today.

Related: The Key to Project Success – It’s all in How You Start!

Headline image by Derek Rosner. It was rendered using Microsoft Copilot Artificial Intelligence and TechSmith SnagIt software.

Roy O. Christensen is a Welding Engineering Technologist who has over 35 years’ experience with oil and gas, pipelines, and other projects. He has authored countless instructions, manuals, plans, proposals, reports, specifications, and other documents that continue to drive success for many projects. He is the founder of the KT Project, which saves organizations significant money and time, by providing key resources to leverage expert knowledge transfer for successful project execution.