In the wake of the coronavirus and collapse in crude oil prices, chemical, and oil and gas, and midstream companies will all slash capital spending (capex) for growth projects to preserve cash. As a result, the U.S. and global chemical investment wave looks to slow considerably in the years ahead.

While major U.S. chemical projects under construction should continue, the fall in Brent crude oil prices and the shrinking of the Brent/U.S. Henry Hub natural gas ratio from the 30s to the mid-teens “puts into question the economics long term”, said Kevin Swift, chief economist of the American Chemistry Council (ACC) speaking on an ICIS webinar on the economic outlook on 19 March.

“This creates an awful lot of uncertainty, and decision-makers don’t like uncertainty,” he added.

This year, U.S.-based Dow had already taken down its capex plan to $1.5bn for 2020 from $2bn in 2019. However, on a 16 March appearance on CNBC’s Mad Money program with Jim Cramer, CEO Jim Fitterling said the company would struggle to meet even the lowered $1.5bn capex target because of limitations on the movement of contractors and engineers given the coronavirus outbreak.

On 18 March, Shell announced the temporary suspension of work on its 1.5m tonne/year cracker under construction in Monaca, Pennsylvania to prevent the spread of the coronavirus. No timeframe was given for when work would resume.

For Dow, after having paid down around $2bn in debt in 2019, it would like to pay off another $500m-$1bn in debt in 2020, said Fitterling. At the end of 2019, Dow had net debt of $14.6bn.

Dow is in the process of starting up its Texas-9 cracker expansion adding 500,000 tonnes/year of ethylene capacity in Freeport by mid-Q2. Among other project plans are a 130,000 tonne/year ethylene expansion in Western Canada by H1 2021 and a 600,000 tonne/year polyethylene (PE) plant on the U.S. Gulf Coast for an H2 2022 start-up.

Canada-based Methanex on 16 March said it is evaluating all capital and operating spending, including its planned Geismar 3 project in Louisiana which would add 1.8m tonnes/year of methanol capacity. Construction on the plant started in late 2019 with planned start-up for mid-2022.

In late January, Methanex announced it was broadening its search for a strategic partner for Geismar 3.

Oil Companies to Pull Back

Major oil companies will also cut capex plans for 2020 and beyond in response to the collapse in oil prices. Importantly, many of these companies had aggressive plans for petrochemical capacity expansion, as they shifted their focus away from transportation fuel and towards chemicals for future growth.

While oil companies have not yet specifically mentioned cuts to chemical projects, all investments should see an impact.

Saudi Aramco, the world’s largest oil producer, is slashing 2020 capex from an expected $35-40bn range indicated in its IPO prospectus, to a level of $25-30bn. This is also down from capex of $33bn in 2019. Aramco’s capex plans for 2021 and beyond are also under review.

“As yet, no one knows precisely the impact on economic activity and energy demand from the coronavirus outbreak, especially in the longer term, and additional efficiencies may be required,” said Aramco chief financial officer Khalid al-Dabbagh, on the company’s Q4 earnings conference call on —.

Aramco has the most ambitious petrochemical expansion plans of any company, with multiple new cracker and derivative projects in Saudi Arabia, China, India and the U.S. It had planned to spend around $100bn towards petrochemical expansions over a decade.

U.S.-based ExxonMobil said on 16 March it is considering significant cuts to capex and operating expenses. The company is building a 1.8m tonne/year joint venture cracker complex with SABIC in Corpus Christi, Texas with a planned start-up in H1 2022, and is planning a cracker complex in China as well.

Other oil companies have also announced capex cuts, including Occidental Petroleum, Apache and Marathon Petroleum. More will surely follow.

Midstream Capex Cuts

North American midstream energy companies are also busy taking down capex plans.

Canada-based midstream energy and petrochemicals company Pembina Pipeline is chopping 2020 capital spending by between Canadian dollar (C$) 900m to 1.1bn ($625-764m) to a level of C$1.2-1.4bn.

A number of projects will be deferred, including Pembina’s investment in the Canada Kuwait Petrochemical Corp (CKPC) petrochemicals joint venture – which involves building an integrated propane dehydrogenation and polypropylene (PDH/PP) complex in Alberta.

Officials previously indicated an H2 2023 in-service timeline for the complex.

A number of other midstream energy companies have announced plans to cut capex, including Targa Resources, Hess Midstream, Enlink Midstream and ONEOK. Enterprise Products is also reviewing its capex program.

Major cuts to capex plans for oil and gas, and midstream energy companies are a long-term problem for the U.S. petrochemical industry, as access to abundant and low-cost natural gas liquids (NGL) feedstocks is its lifeblood.

The U.S. shale gas cost advantage has spurred hundreds of billions of dollars in chemical investment. With the crash in crude oil prices, which has severely diminished this advantage, the investment boom is clearly under threat.

“We could see delays in decisions for projects that were going to start up in 2025. Companies can certainly afford to delay a decision by a quarter or two,” said the ACC’s Swift.

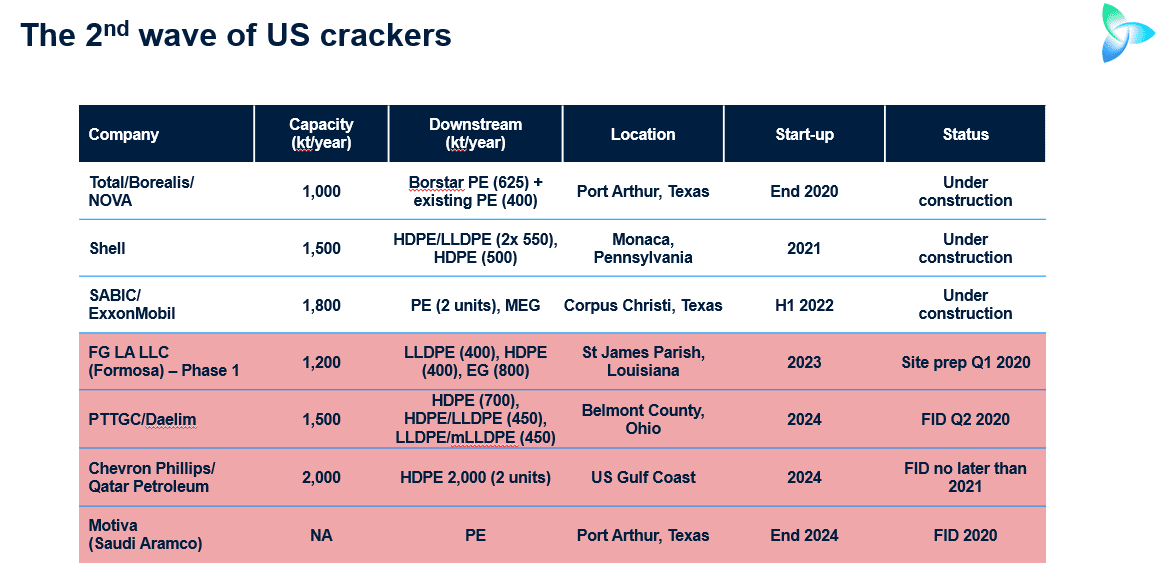

Planned U.S. cracker projects for start-up further down the road in 2023-2025 where final investment decisions (FIDs) have yet to be made include those by FG LA LLC (Formosa), PTTGC/Daelim, Chevron Phillips Chemical/Qatar Petroleum, and Motiva (Saudi Aramco).

Additional reporting by Stefan Baumgarten, ICIS